A kind of preparation method of semi-aromatic polyamide

A technology for semi-aromatic and polyamide, which is applied in the field of preparation of semi-aromatic polyamide, can solve the problems that the low-temperature solution polycondensation method is not suitable for industrialized large-scale production, cannot be operated continuously, and requires high reaction equipment, and achieves low cost, The effect of low production cost and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

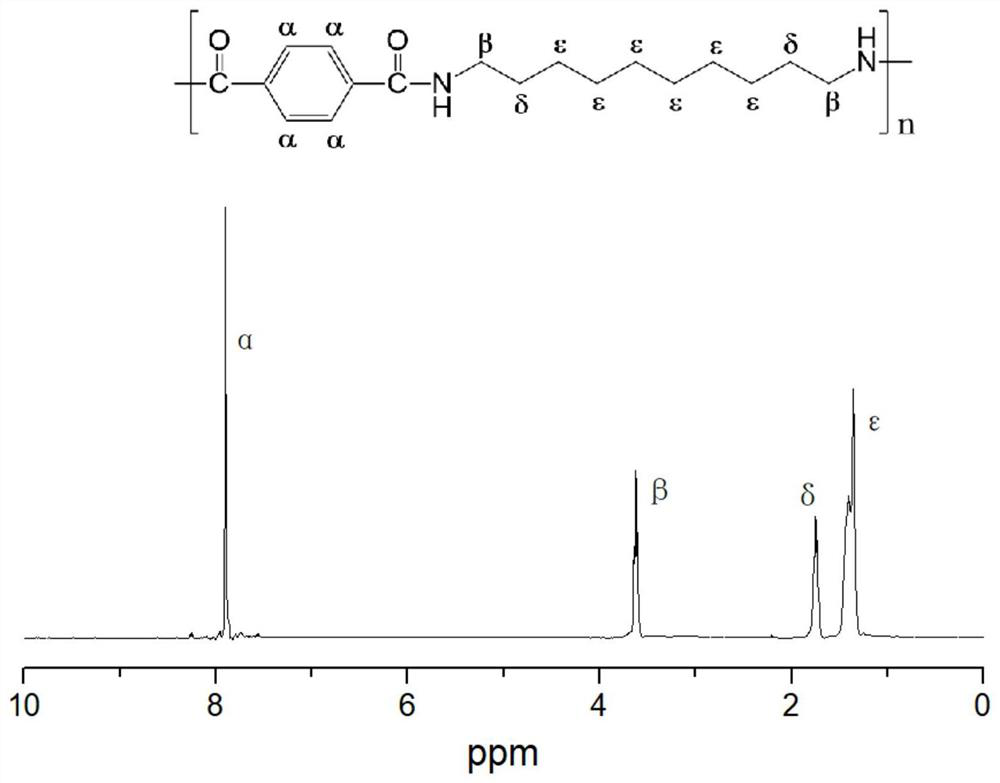

[0047] The preparation of semiaromatic polyamide comprises the steps:

[0048] 1mol (ie 166.13g) terephthalic acid, 1.01mol (ie 174.05g) decanediamine, 0.01mol (ie 1.22g) benzoic acid, 0.34g sodium hypophosphite, 1.00g N,N'-bis-( Add 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine and 510g deionized water into the high-temperature and high-pressure polymerization reactor, replace the air in the reactor with nitrogen for 10 times, start stirring, and The temperature is 100rpm, the temperature is raised to 80°C within 0.5h, and the salt-forming reaction is carried out at a constant temperature. The time of the salt-forming reaction is 1h; after the completion of the salt-forming reaction, the temperature is raised to 220°C within 2h, during which the pressure is controlled by discharging the gas in the kettle No more than 2.8MPa, pre-polymerization at constant temperature, the time of the pre-polymerization is 0.5h, after the completion of the pre-polymerizat...

Embodiment 2

[0051] For the preparation of semi-aromatic polyamide, the method steps are the same as in Example 1, except that the rotational speed of the agitator is changed to 120 rpm. The product performance test results are shown in Table 1.

Embodiment 3

[0053] The preparation of the semi-aromatic polyamide is the same as in Example 1, except that the prepolymerization temperature is changed to 210°C. The product performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com