A method for preparing levoglucosan from agricultural and forestry waste

A technology of agricultural and forestry waste and levoglucosan, which is applied in the field of biomass energy utilization, can solve the problems of difficult recycling, low yield of levoglucosan, and high extraction cost, so as to increase yield and realize high-value utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] S1: Weigh 10g of rice stalks and place them in a 500ml high-temperature and high-pressure hydrothermal reaction kettle, add 100ml of water, and fill with CO with an initial pressure of 2MPa. 2 , at CO 2 Under the atmosphere, the temperature was raised to 200°C at a rate of 8°C / min, and stayed for 30 minutes for hydrothermal pretreatment;

[0044] S2: After the reaction is completed, the reaction mixture is vacuum filtered and separated, and the obtained solid product is dried;

[0045] S3: CO is introduced into the fixed bed 2 As the pyrolysis carrier gas, the flow rate is set to 200ml / min. After the air in the reactor is exhausted, the dried hydrothermal coke is pyrolyzed at 360°C, and the volatile matter is condensed at 120°C to obtain a liquid product, which is analyzed by gas chromatography Wherein the content of levoglucosan.

[0046] Further, after the present embodiment is analyzed by gas chromatography, the results are as follows Figure 4 As shown, it is ca...

Embodiment 2

[0048] S1: Weigh 10g of rice straw and place it in a 500ml high-temperature and high-pressure hydrothermal reaction kettle, add 100ml of water, and fill it with CO with an initial pressure of 1.5MPa. 2 , at CO 2 Under the atmosphere, the temperature was raised to 200°C at a rate of 8°C / min, and stayed for 30 minutes for hydrothermal pretreatment;

[0049] S2: After the reaction is completed, the reaction mixture is vacuum filtered and separated, and the obtained solid product is dried;

[0050] S3: CO is introduced into the fixed bed 2 As the pyrolysis carrier gas, the flow rate is set to 200ml / min. After the air in the reactor is exhausted, the dried hydrothermal coke is pyrolyzed at 380°C, and the liquid product is obtained after condensing the volatile matter at 140°C. Analyze it by gas chromatography Levoglucosan content.

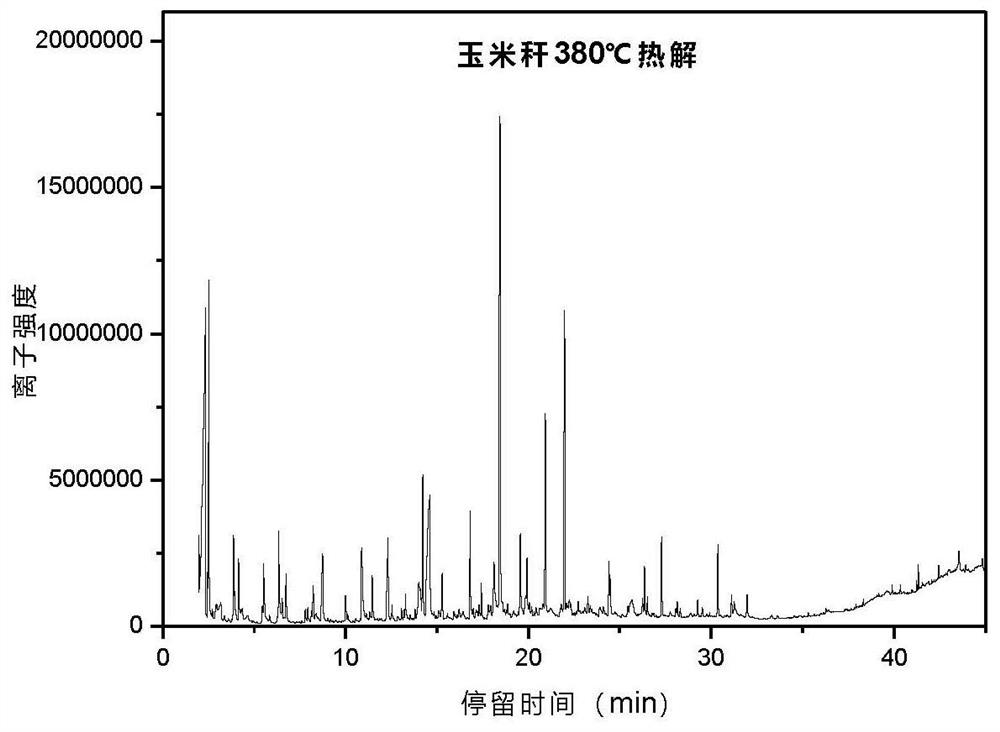

[0051] Further, after the present embodiment is analyzed by gas chromatography, the results are as follows Figure 5 As shown, it is calculated tha...

Embodiment 3

[0053] S1: Weigh 10g of rice stalks and place them in a 500ml high-temperature and high-pressure hydrothermal reaction kettle, add 100ml of water, and fill with CO with an initial pressure of 1MPa. 2 , at CO 2 Under the atmosphere, the temperature was raised to 200°C at a rate of 8°C / min, and stayed for 30 minutes for hydrothermal pretreatment;

[0054] S2: After the reaction is completed, the reaction mixture is vacuum filtered and separated, and the obtained solid product is dried;

[0055] S3: CO is introduced into the fixed bed 2 As the pyrolysis carrier gas, the flow rate is set to 200ml / min. After the air in the reactor is exhausted, the dried hydrothermal coke is pyrolyzed at 400°C, and the liquid product is obtained after condensing the volatile matter at 160°C. Analyze it by gas chromatography Levoglucosan content.

[0056] Further, in this example, after gas chromatography analysis, it is calculated that the relative content of levoglucosan is 28.11%, and the yiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com