Filter-bag non-woven fabric hot-melting structure

A technology of non-woven fabric and filter bag, which is applied in the field of non-woven fabric hot-melt structure of filter bag, which can solve the problems of affecting the filtering effect, poor filtering quality, and reduced filtering area, so as to ensure the filtering area and filtering speed of the filter bag , the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

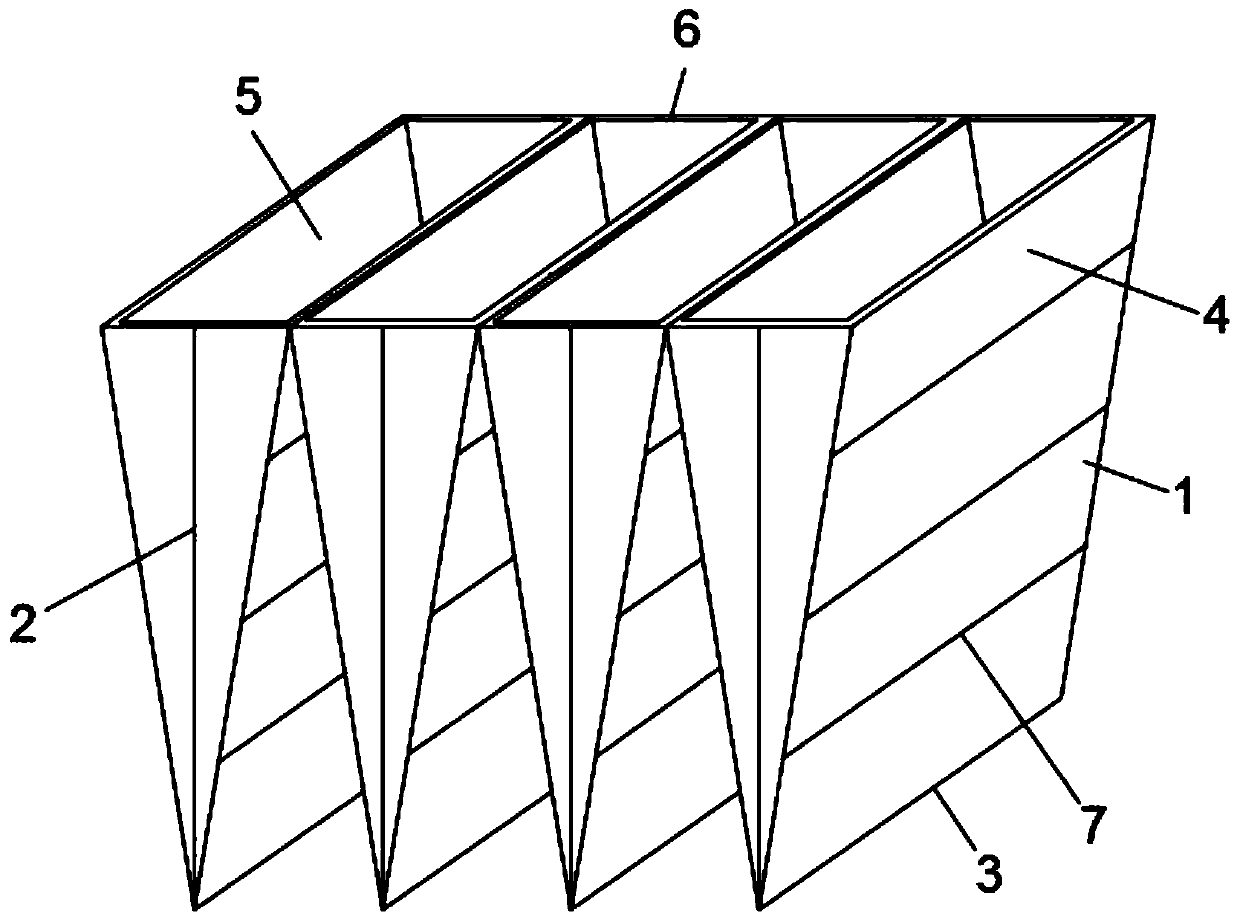

[0017] refer to figure 1 , filter bag non-woven hot-melt structure, including a bag filter composed of a plurality of filter bag monomers 1, the outer ring of the bag filter is equipped with an outer frame, and the bag mouth of each filter bag monomer 1 is A support frame is fixed, and the outer wall of the support frame is fixed on the inner wall of the outer frame. By setting the support frame, the strength of the bag mouth of the filter bag monomer 1 is enhanced to ensure that the bag mouth does not deform when the airflow blows in. Each filter The bag monomer 1 is formed by bonding two filter cloths to each other. The two sides of the two filter cloths are thermally fused through the side bonding line 2, and the lower sides of the two filter cloths are thermally bonded through the lower bonding line 3. The adjacent side bonding line 2 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com