Portable foam brush

A portable, foam technology for brushes, cleaning methods using liquids, shipping and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

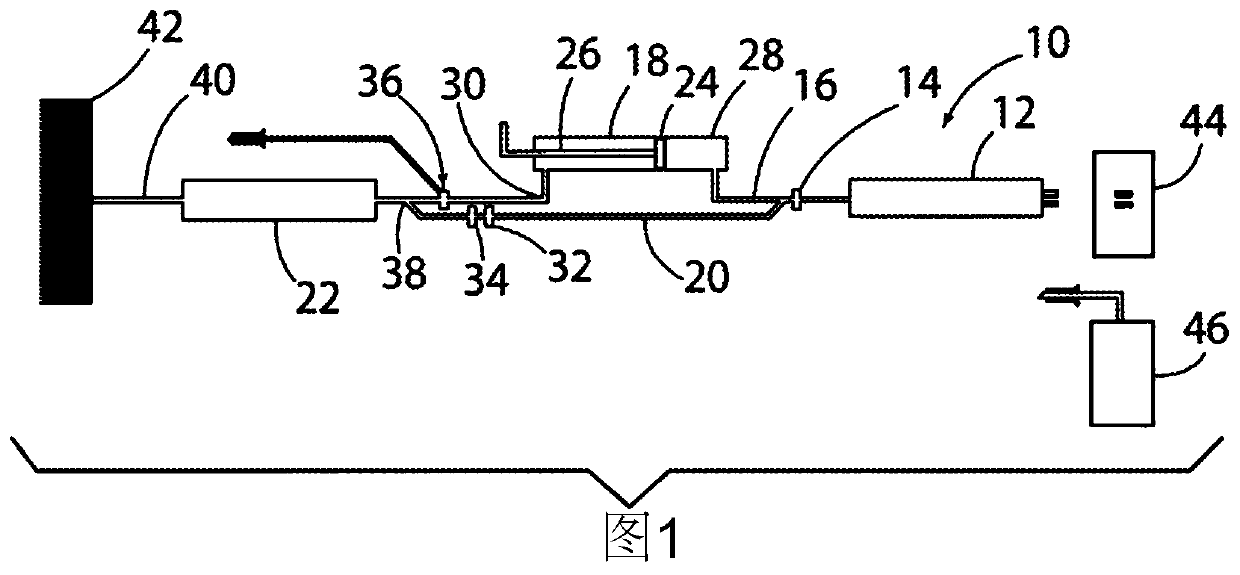

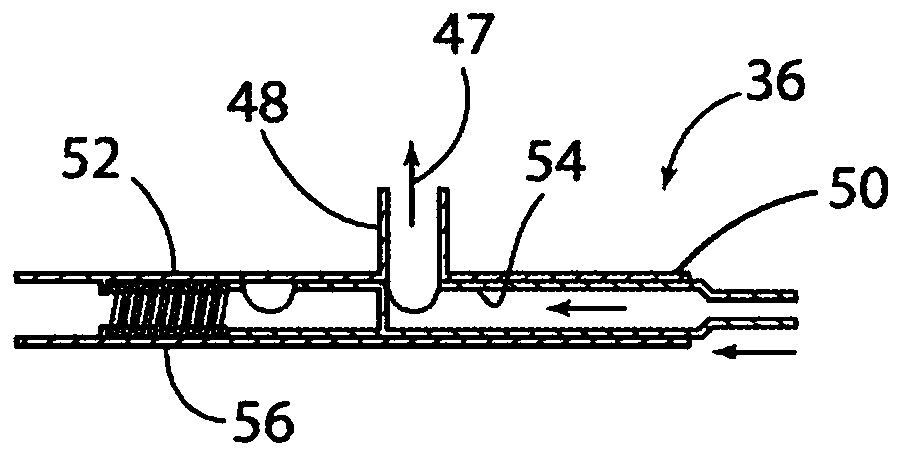

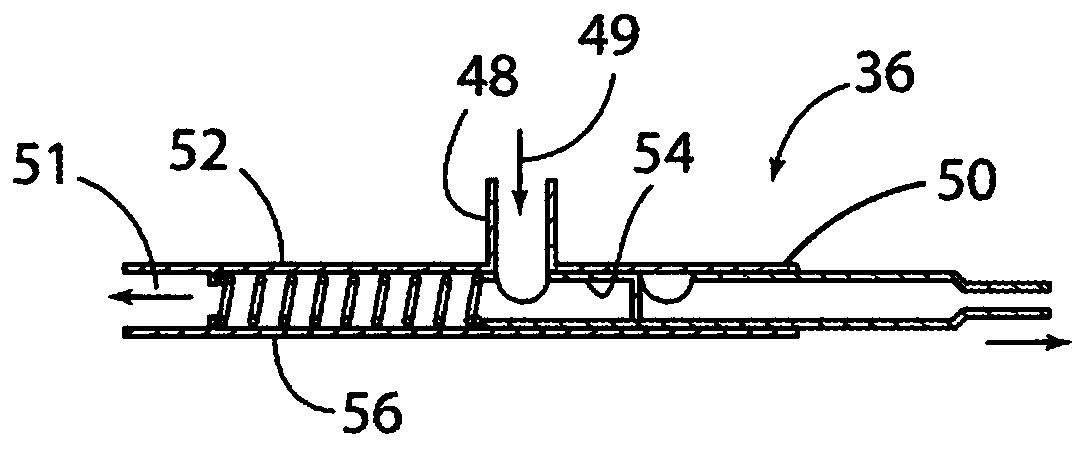

[0061] This article describes and Figure 1 to Figure 42 Various embodiments and aspects of a portable foam brush are shown in the exemplary embodiment of . It should be noted that any dimensions provided in the figures are for illustrative purposes only and are provided to aid in the understanding of the embodiments. According to one approach, the components of a portable foam brush may include a base, a water supply, an air compressor, a soap reservoir, a foaming chamber, and a brush. According to another approach, components of a portable foam brush may include a battery-operated air compressor, a liquid soap reservoir, a foaming chamber, and a brush tip. The brush end is adapted to attach a bristle assembly for brushing. An air compressor supplies air to the soap reservoir to allow soap to enter the foaming chamber. The air compressor also independently supplies air to the foaming chamber for mixing with the soap in the foaming chamber to form the foam and force the foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com