Position sensorless brushless DC motor start control and low speed operation method

A brushed DC motor, low-speed operation technology, applied in the direction of motor generator control, electronic commutation motor control, excitation or armature current control, etc., can solve problems such as excessive starting current, large average torque, and difficult starting process , to achieve fast and accurate starting, reduce high-frequency harmonics, and widen the speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Image 6 Middle (a) is the torque before improvement (b) is the torque after improvement (c) is the comparison chart of torque before and after improvement.

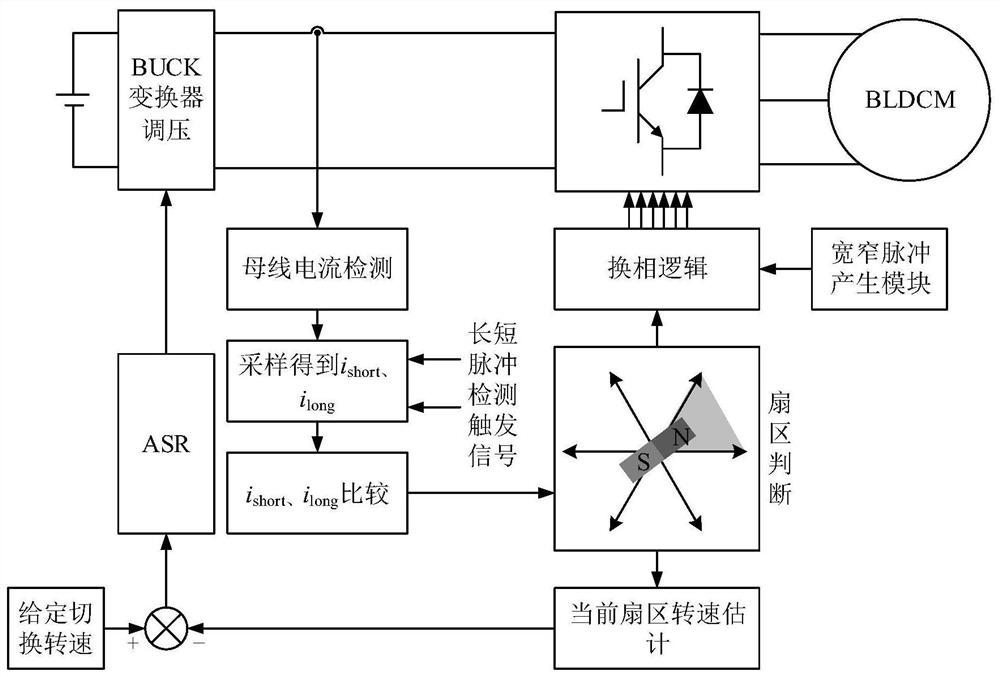

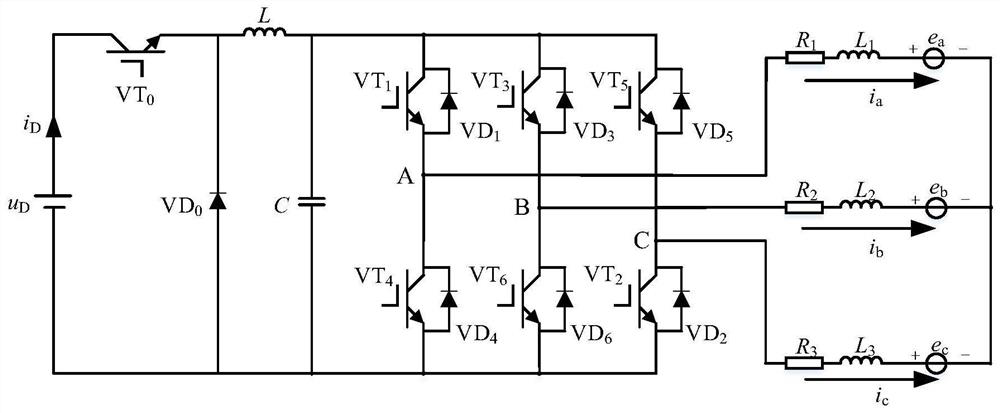

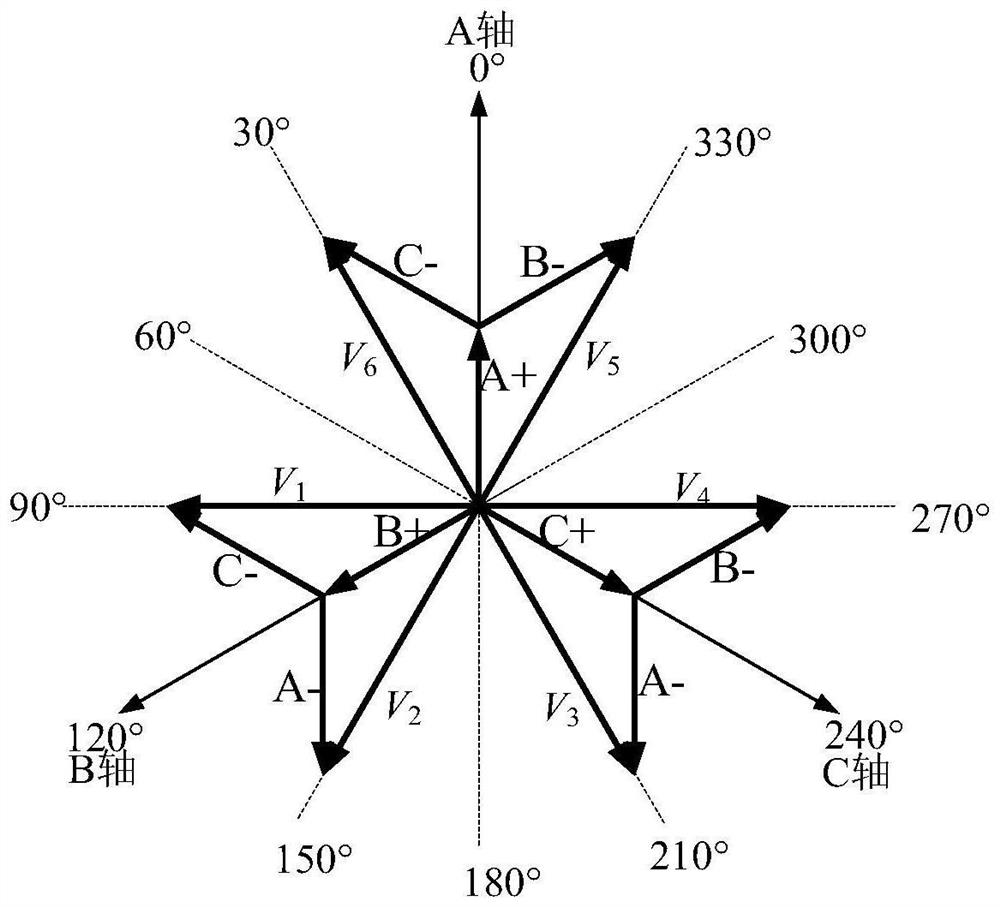

[0029] An improved sensorless brushless DC motor (Brushless DC Motor, hereinafter referred to as BLDCM) method for starting control and low-speed operation, including a Buck converter, a brushless DC motor, a pulse generation module, a position detection module, a controller and a rotating speed Calculation module: generate wide and narrow pulses through the pulse generation module, the position detection module uses the current sensor to detect the current response under the action of the pulse generation module to determine the current position of the rotor, and uses the speed calculation module to estimate the approximate speed of the rotor to form a closed loop of speed, and finally through the Buck tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com