Adaptive PCB plate defect visual positioning detection and classification system

A PCB board, visual positioning technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of high risk, difficult detection, low efficiency, etc., and achieve the effect of high precision, fast speed and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

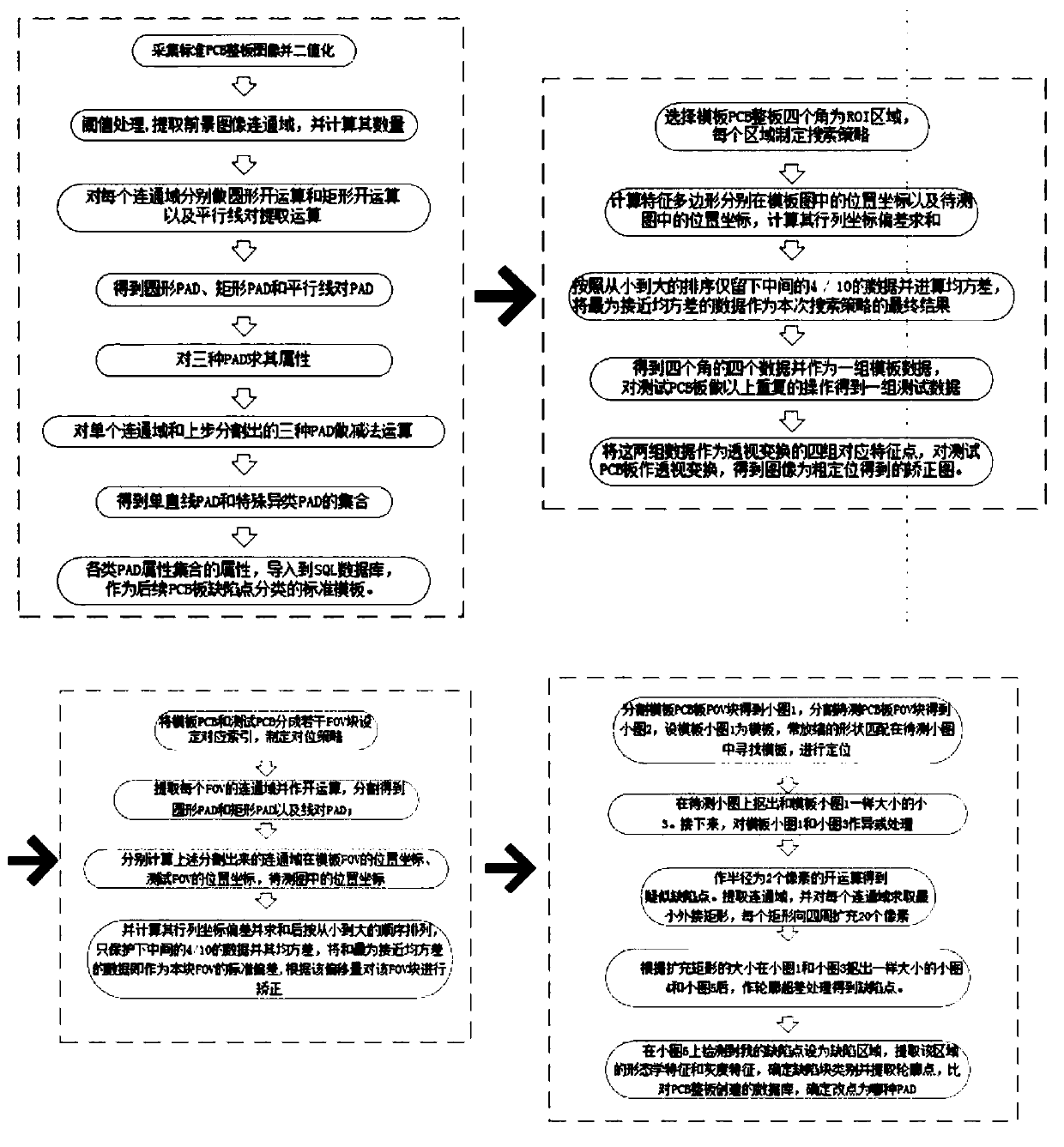

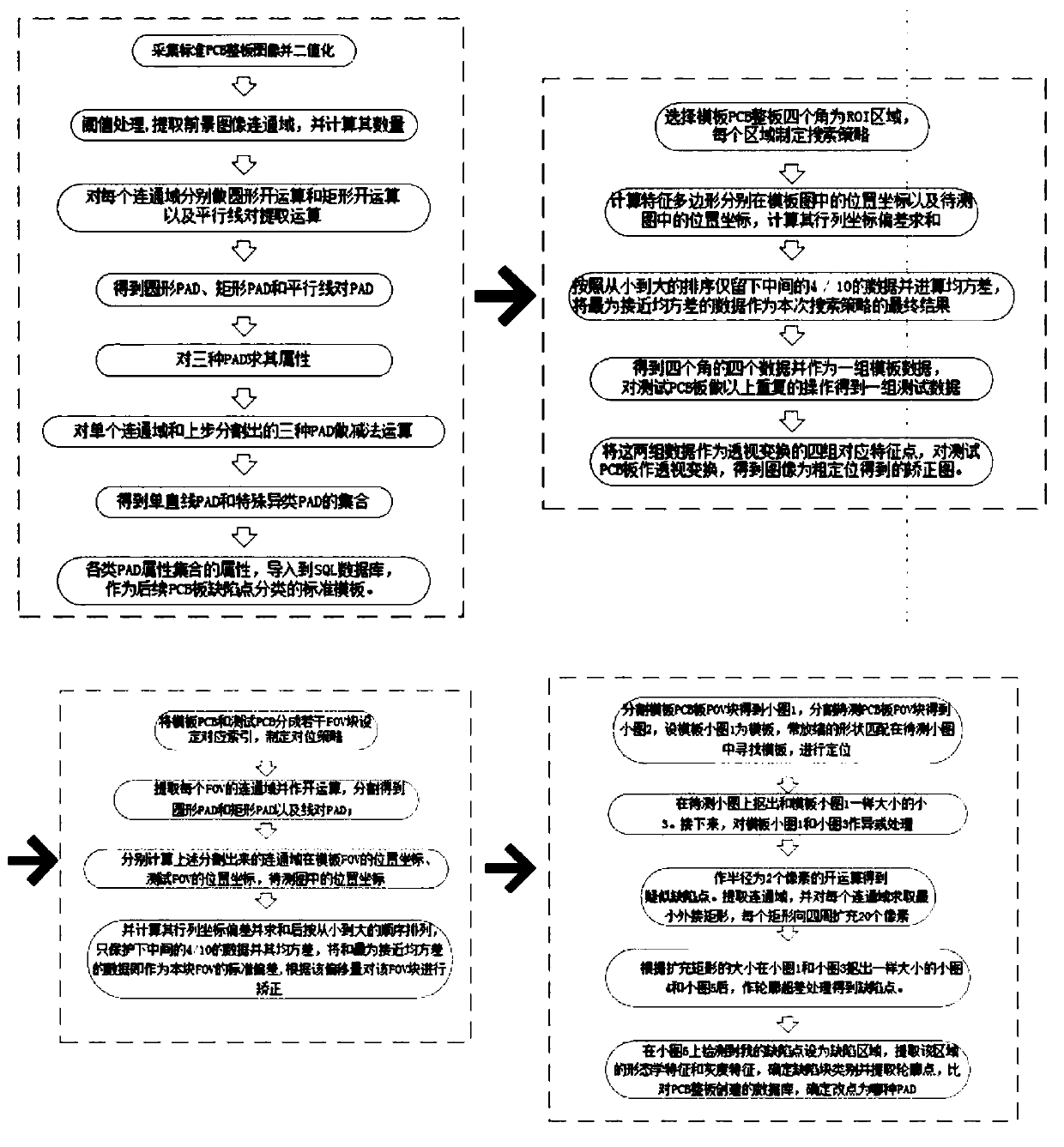

[0026] Embodiment: An adaptive PCB board defect visual positioning detection and classification system.

[0027]An adaptive PCB board defect visual positioning detection and classification system, including the offline PCB board pixel classification module, the online front-end PCB board positioning module, the online middle-end defect detection module, the online end defect classification module, and the offline The pixel point classification module of the whole PCB board at the end mainly classifies the pixels of different PADs on the whole PCB board, including circular PADs, square PADs, parallel line PADs, single straight line PADs, special heterogeneous PADs, etc. The preparation of the classification module is characterized in that the PCB positioning module at the front end of the line mainly includes coarse positioning and fine positioning; the defect detection module at the middle end of the line mainly adopts the method of multi-template matching and out-of-tolerance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com