Fiber-integrated interferometer series structure three-dimensional space distributed deformation sensor

A technology of deformation sensor and series structure, which is applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of spectrum demodulation and aliasing at detection points, and achieve the elimination of temperature cross-sensitivity effects, improve high temperature resistance, and eliminate temperature The effect of cross-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

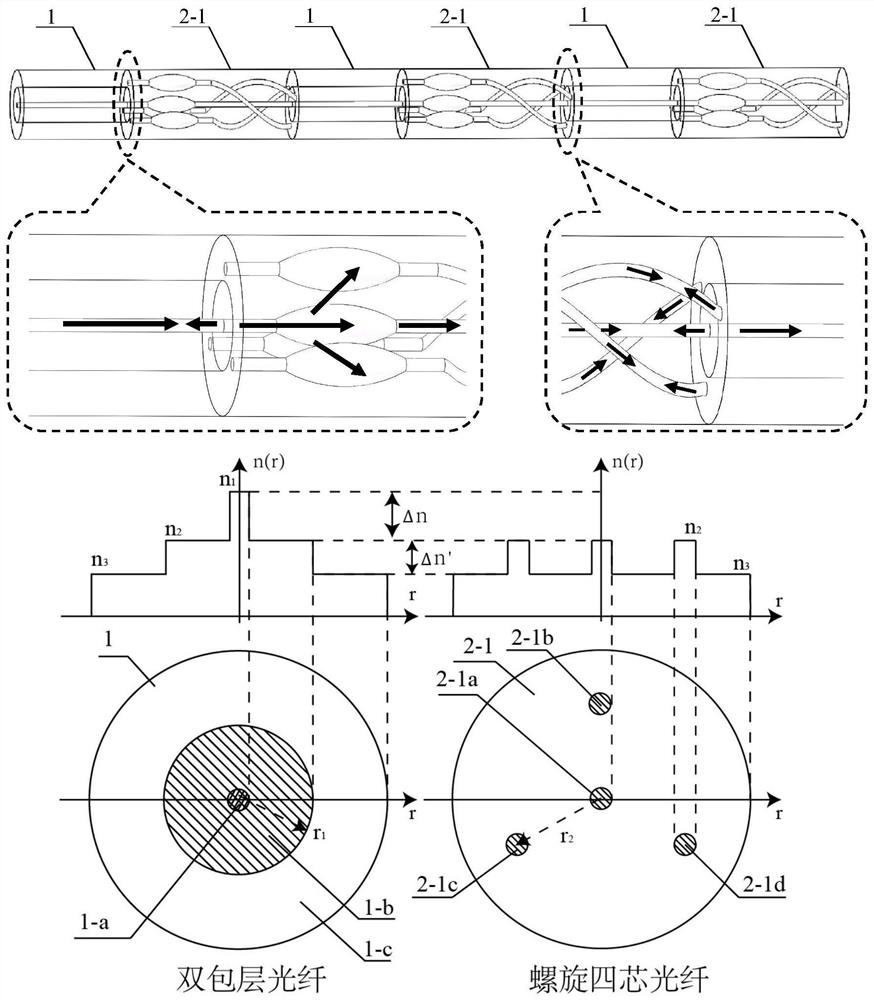

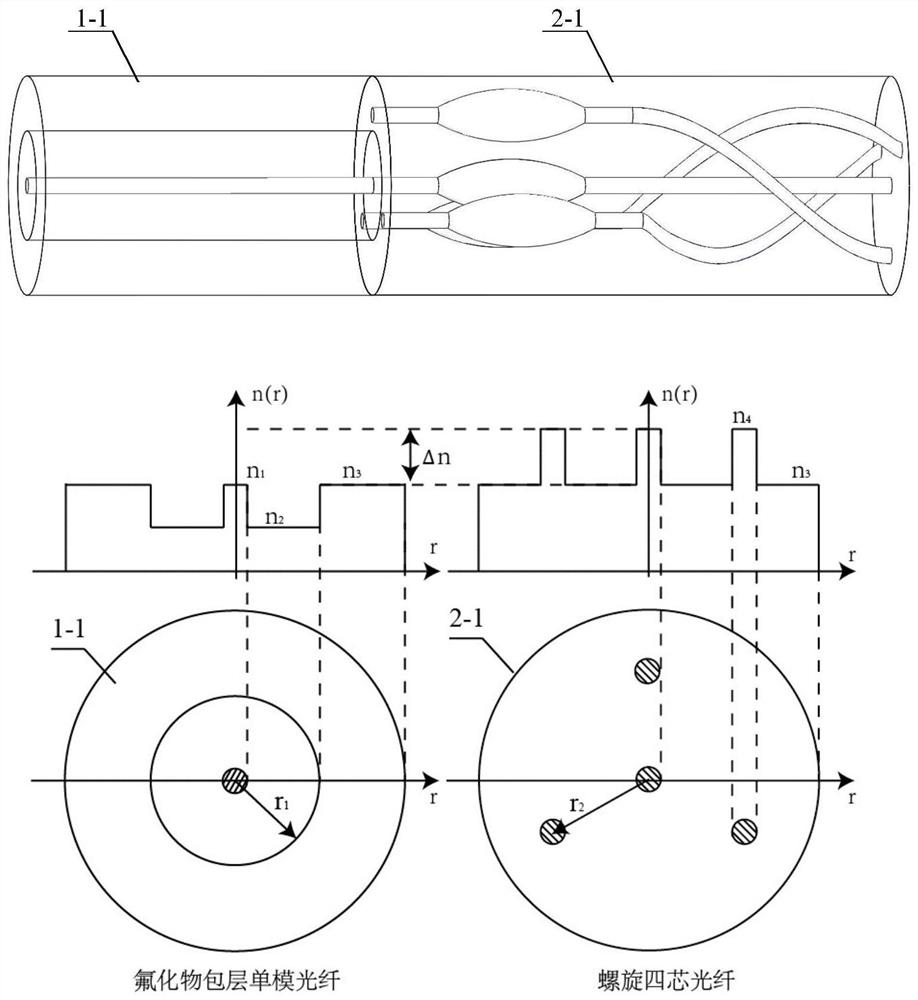

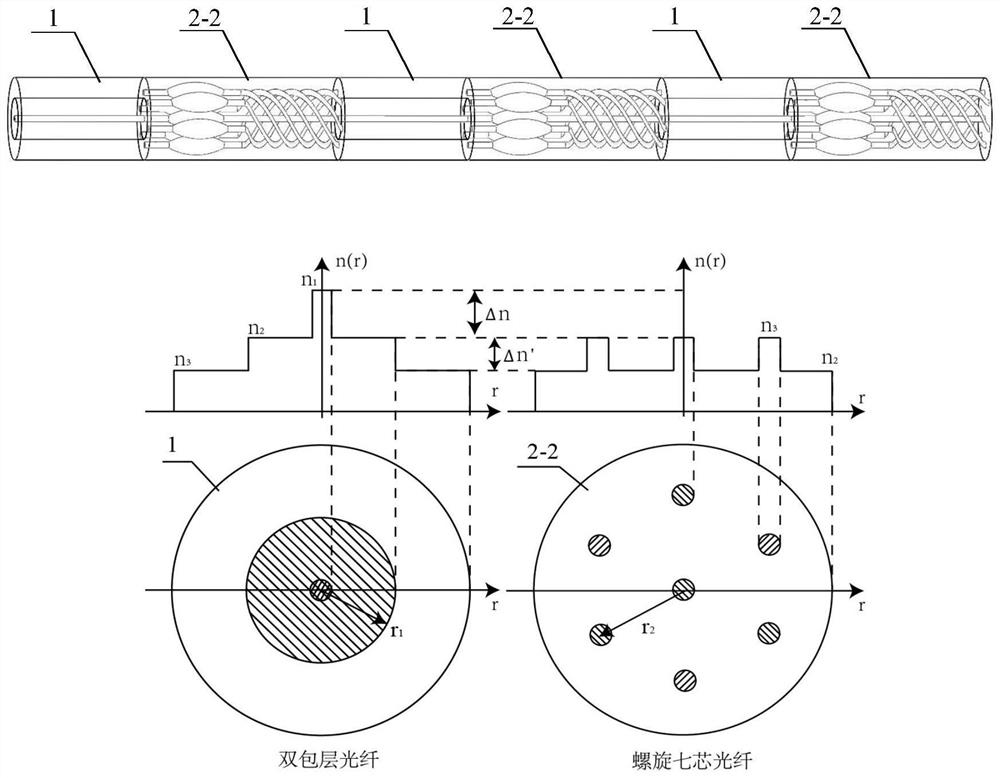

[0034] Example: figure 1 It is a structural schematic diagram of a fiber-integrated interferometer series structure three-dimensional space distributed deformation sensor, and it is also a specific implementation mode of the sensor.

[0035] In order to analyze the optical path difference of the four fiber cores of the helical quadruple fiber 2-1 due to bending, the establishment of Figure 5 The reference coordinates of the shown helical quadruple-core optical fiber 2-1 in a bent state. For the curved coordinate system of the helical four-core fiber 2-1 in the figure, it is assumed that the length from the thermal coupling of the helical four-core fiber 2-1 to the end face of the four-core fiber is L, and the outer three cores 2-1b / 2-1c / 2- The distance from 1d to the central core 2-1a is r.

[0036] The optical path calculation is determined by the following formula:

[0037] L=n eff l (3)

[0038] In the formula, L is the scanning distance of the translation stage, n e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com