A vector strain gauge based on micro-nano multi-core special optical fiber

A technology of special optical fiber and multi-core optical fiber, which is applied in the field of sensing, can solve the problems of low sensitivity of optical fiber stress sensor and the inability to detect the direction of stress, and achieve the effects of promoting development, enhancing flexibility, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below through technical texts and drawings.

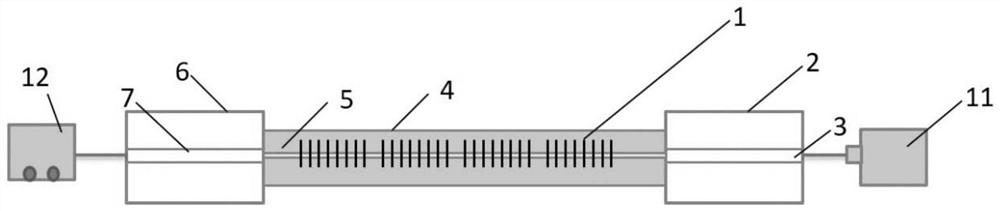

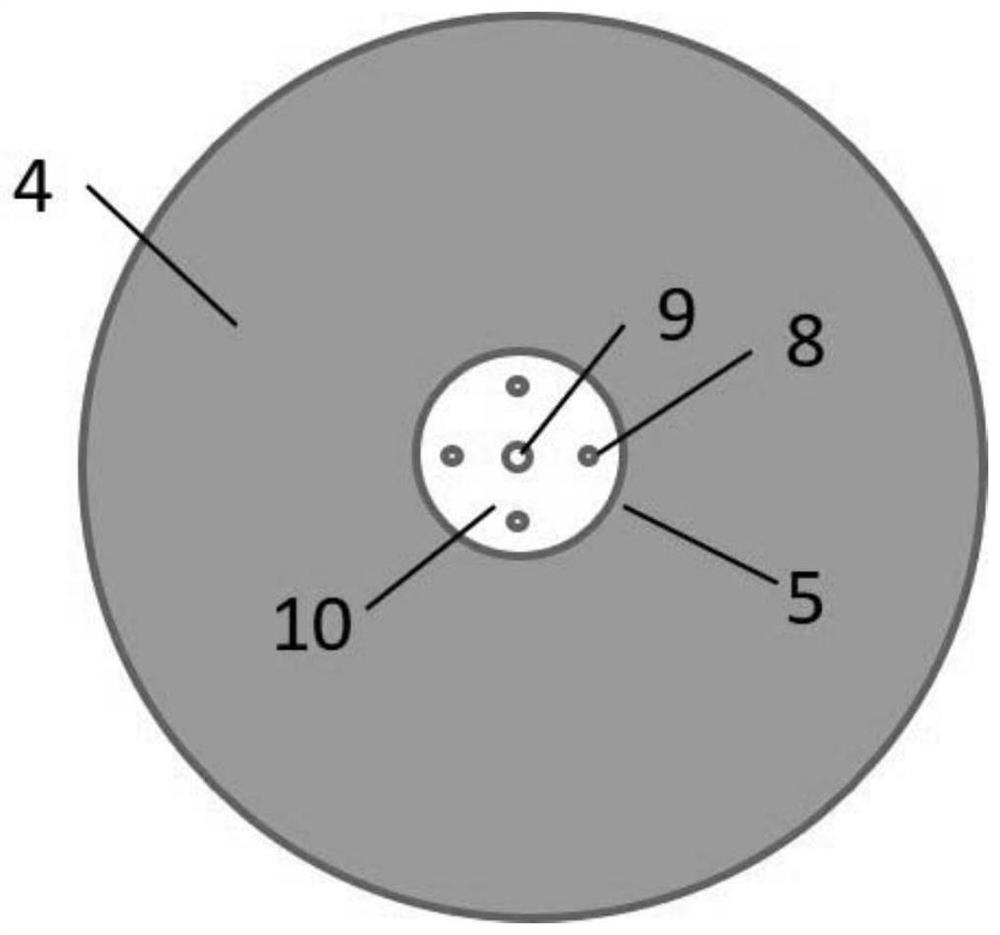

[0022] As shown in the figure, a vector strain gauge based on the micro-nano multi-core special optical fiber of the present invention has a main body that is a cascaded structure obtained by welding the micro-nano multi-core special optical fiber 5 with the single-mode optical fiber A2 and the single-mode optical fiber B6; The broadband light source 11 emits light signals, and after passing through the cascade structure, a set of output spectra will be obtained on the spectrum analyzer 12, and when the external pressure acts on the cascade structure, it will deform and bend, so that the output spectrum is consistent with zero There is an offset when the pressure is on.

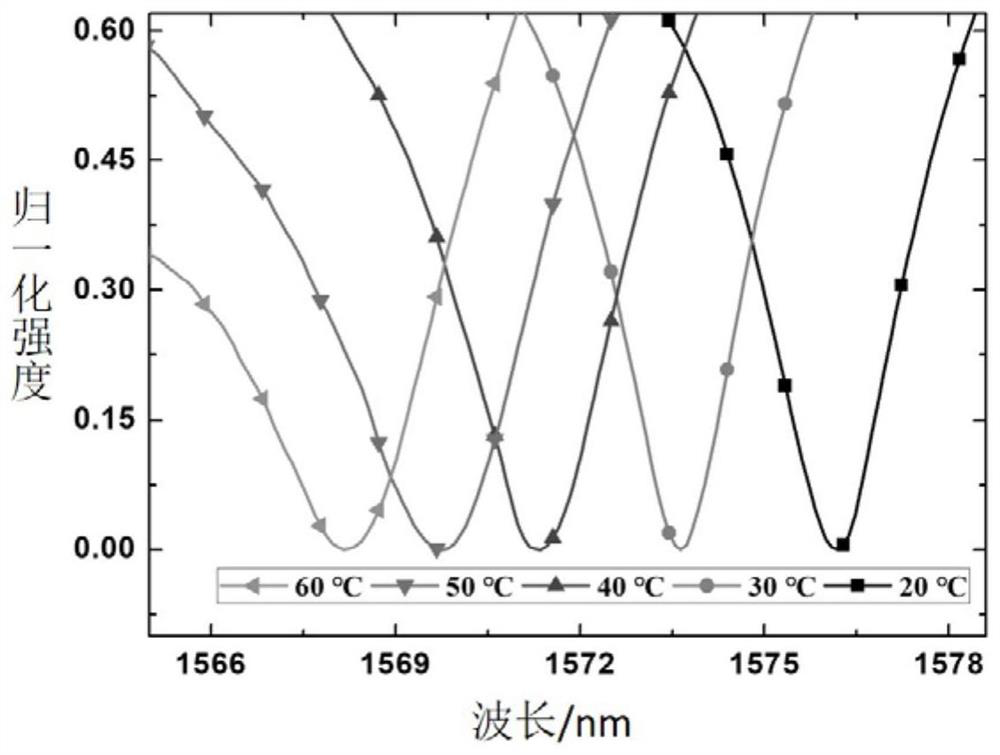

[0023] Among them, with the bending of the cascaded structure of the grating 1, the characteristic wavelength on its interference spectrum will move by Δλ 1 , the distance between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com