A structure of a highly sealed liquid flow control ball valve which is convenient for connection

A high-sealing, liquid technology, used in valve devices, cocks including cut-off devices, mechanical equipment, etc., can solve problems such as poor flow regulation effect of ball valves, and achieve the effect of enhanced sealing effect and reduced airbag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

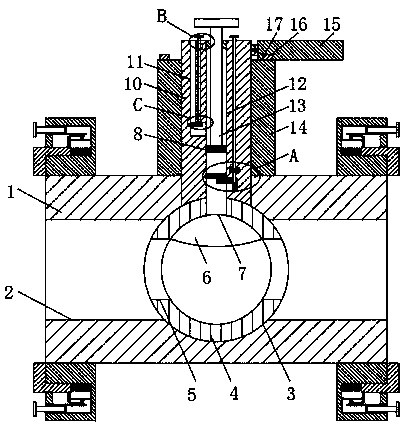

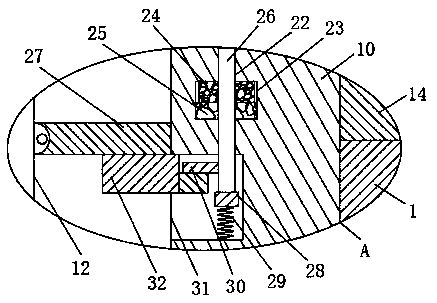

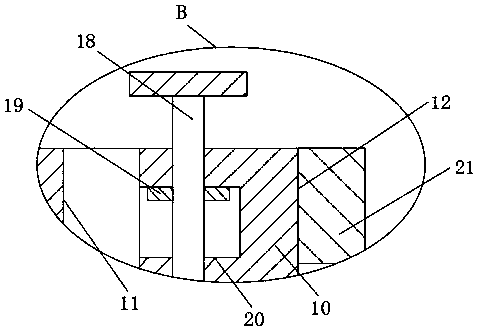

[0023] Reference Figure 1-4 , An easy-to-connect structure of a high-sealing liquid flow control ball valve, including a housing 1, a water channel 2 is provided on the side wall of the housing 1, a rotating groove 3 is provided on the inner wall of the water channel 2, and the inner wall of the rotating groove 3 is slidingly connected with a hollow The inner wall of the symmetrical two ends of the sphere 4 is provided with a circulation hole 5, the upper inner wall of the sphere 4 is glued with an airbag 6, and the upper end side wall of the sphere 4 is penetrated with a vent groove 7, which communicates with the interior of the airbag 6. The upper end of the sphere 4 is welded with a rotating shaft 10, and the upper end of the shell 1 is welded with a rotating shell 14. The rotating shaft 10 penetrates the upper wall of the shell 1 and the rotatable shell 14 and extends to the upper end of the rotating shell 14. The inside of the rotating shaft 10 is provided with a limited f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com