Automatic water quality sampling equipment

An automatic sampling and equipment technology, applied in the direction of sampling devices, etc., can solve the problems of increasing the difficulty of the work of the staff and reducing the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

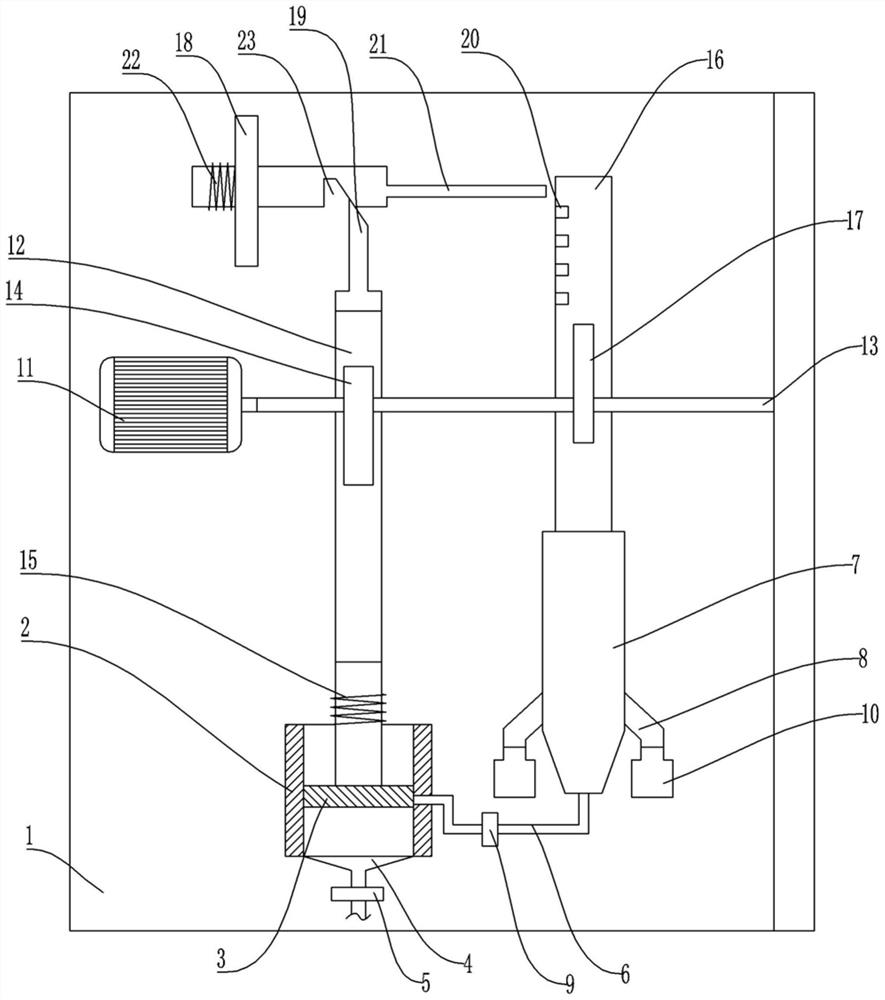

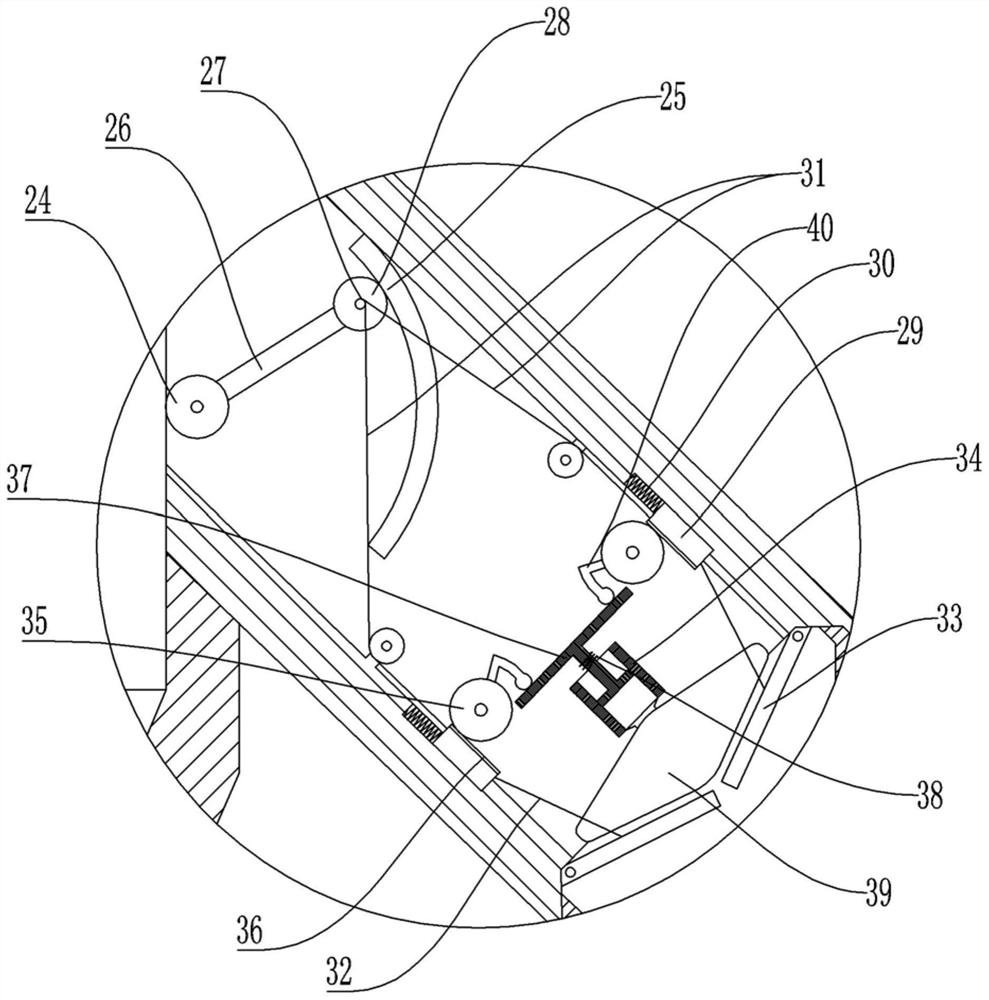

[0027] Basic as attached figure 1 , attached figure 2 And attached image 3 Shown: automatic sampling equipment for water quality, including machine base 1, driving wheels are installed at the bottom of machine base 1; water pumping mechanism and sampling mechanism are arranged on machine base 1, water pumping mechanism includes piston cylinder 2 fixedly connected with machine base 1 and The piston block 3 sliding in the piston cylinder 2, the piston cylinder 2 is connected with the water inlet pipe 4, and the first one-way valve 5 for the fluid to flow from the water inlet pipe 4 to the piston cylinder 2 in one direction is installed on the water inlet pipe 4; the piston cylinder The side wall of 2 communicates with outlet pipe 6.

[0028]The sampling mechanism includes a main pipe 7 and two branch pipes 8, the main pipe 7 is fixedly connected to the machine base 1, and the two branch pipes 8 are symmetrically arranged on both sides of the main pipe 7 with the main pipe 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com