One-bath dyeing method of polyester-cotton knitted fabrics

A technology of same-bath dyeing and polyester-cotton needles, applied in the field of textile printing and dyeing, can solve the problems of low production efficiency, short process flow, long process flow, etc., and achieve the effects of improving production efficiency, shortening the dyeing and finishing process, and reducing the chroma of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0041] The same-bath dyeing method of polyester-cotton knitted fabric in this embodiment is to dye black on T / C single jersey (65% / 35%), and the specific steps are as follows:

[0042] ① Cationic modification of T / C single-sided fabric.

[0043] Arrange the above T / C on one side in the modifying solution, and evenly paddle it with a rolling car to achieve a surplus rate of 80%, and then stack it at room temperature for 12 hours.

[0044] The formula of the modified liquid is as follows: cationic modifier 100g / L, sodium hydroxide 30g / L, penetrant 10g / L, and the rest is water.

[0045] The cationic modifier is 3-chloro-2-hydroxypropyltrimethylammonium chloride cationic quaternary ammonium salt.

[0046] The penetrating agent is strong alkali-resistant non-silicon penetrating agent FS.

[0047] ②Arrange one side of T / C after cationic modification in the overflow dye vat for neutralization and cleaning, the temperature is 70°C, and the time is 15 minutes.

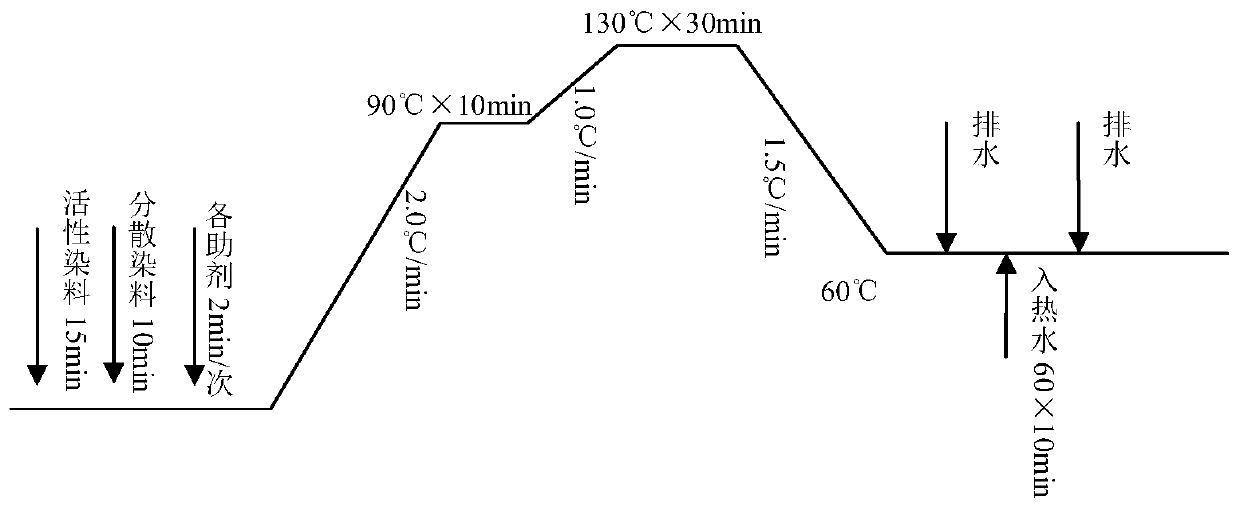

[0048] ③ Dyeing in t...

Embodiment 2)

[0057] The same-bath dyeing method of polyester-cotton knitted fabric in this embodiment is to dye emerald blue on T / C single jersey (65% / 35%), and the specific steps are as follows:

[0058] ① Cationic modification of T / C single-sided fabric.

[0059] Arrange the above T / C on one side in the modifying solution, and evenly paddle it with a rolling car to achieve a surplus rate of 80%, and then stack it at room temperature for 12 hours.

[0060] The formula of the modified liquid is as follows: cationic modifier 80g / L, sodium hydroxide 24g / L, penetrant 8g / L, and the rest is water.

[0061] The cationic modifier is 3-chloro-2-hydroxypropyltrimethylammonium chloride cationic quaternary ammonium salt.

[0062] The penetrating agent is strong alkali-resistant non-silicon penetrating agent FS.

[0063] ② Arrange one side of T / C after cationic modification in the overflow dye vat for neutralization and cleaning, the temperature is 80 ℃, and the time is 20 minutes.

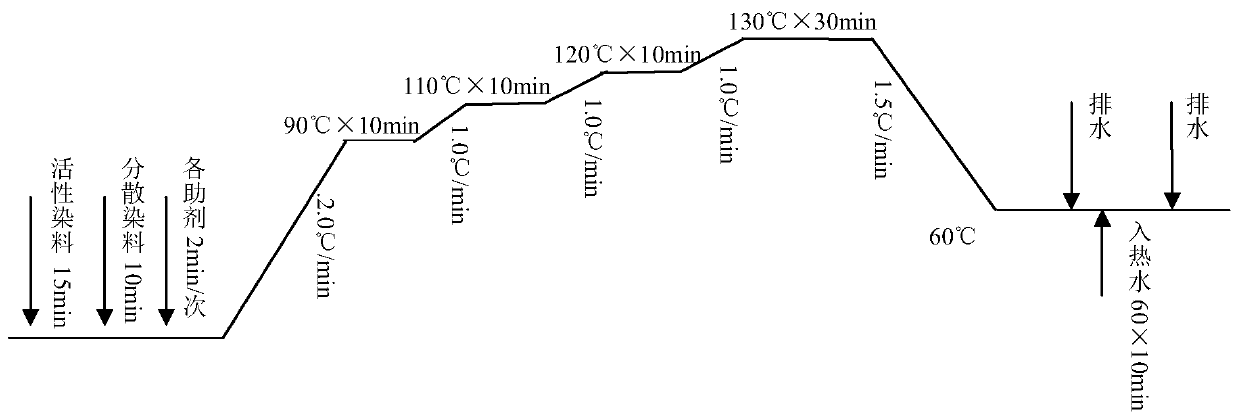

[0064] ②'Bleac...

Embodiment 3)

[0075] The same-bath dyeing method of polyester-cotton knitted fabric in this embodiment is to dye red on T / C single jersey (65% / 35%), and the specific steps are as follows:

[0076] ① Cationic modification of T / C single-sided fabric.

[0077] Arrange the above T / C on one side in the modifying solution, evenly paddle and paddle, the excess rate is 80%, and then stack at room temperature for 12 hours.

[0078] The formula of the modified liquid is as follows: cationic modifier 70g / L, sodium hydroxide 21g / L, penetrant 7g / L, and the rest is water.

[0079] The cationic modifier is 3-chloro-2-hydroxypropyltrimethylammonium chloride cationic quaternary ammonium salt.

[0080] The penetrating agent is strong alkali-resistant non-silicon penetrating agent FS.

[0081] ② Arrange one side of T / C after cationic modification in the overflow dye vat for neutralization and cleaning, the temperature is 80 ℃, and the time is 20 minutes.

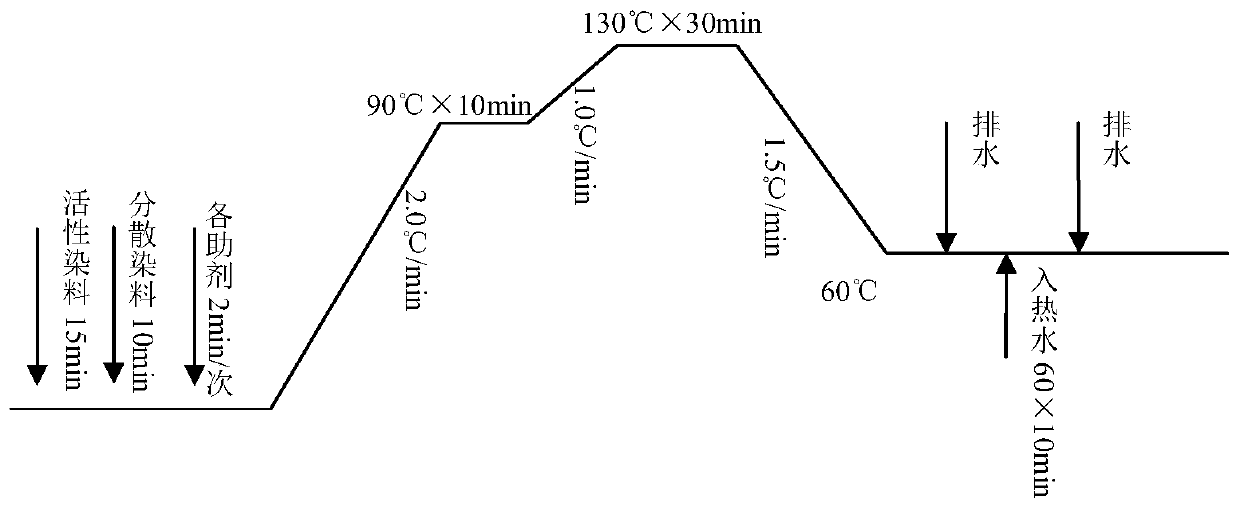

[0082] ②'Bleaching is carried out according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com