Garment parts separation mechanism and garment parts separation method

A separation mechanism and separation method technology, applied in the field of cutting bed, can solve the problems of multi-layer fabrics and small pieces that cannot be sucked up, so as to improve the level of production automation and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

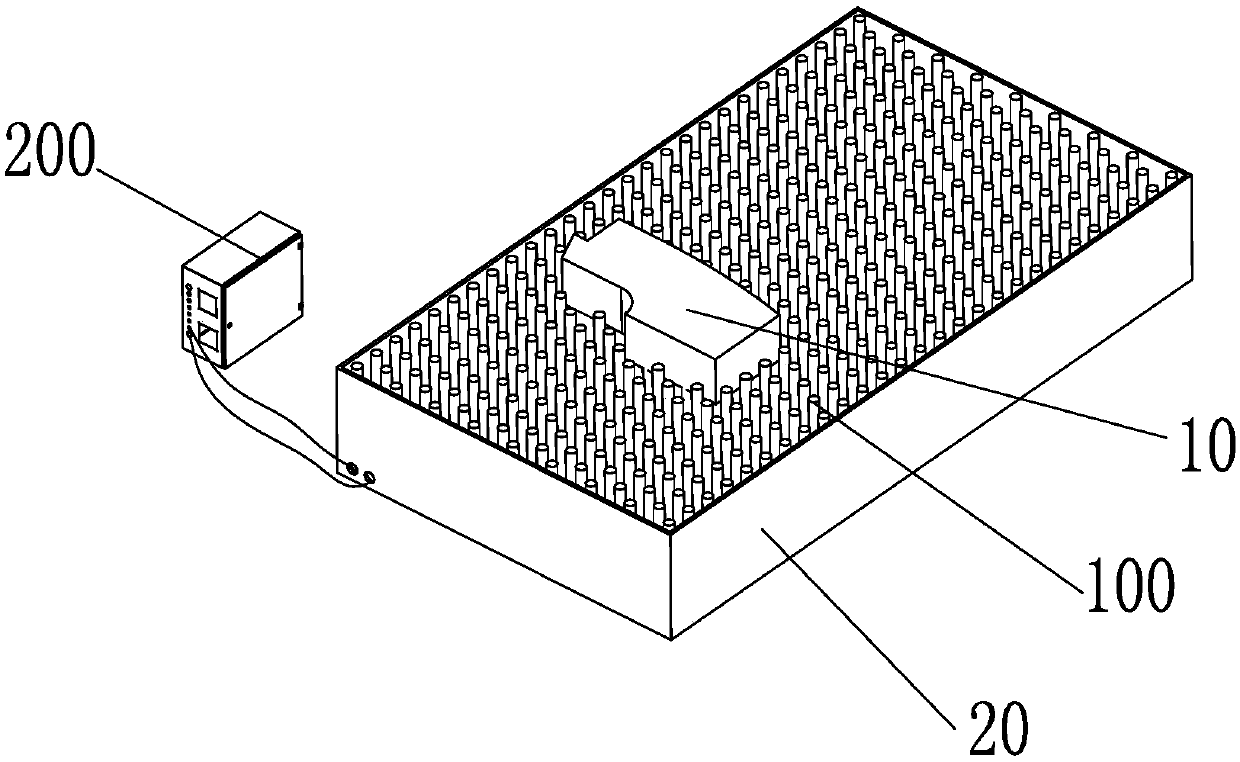

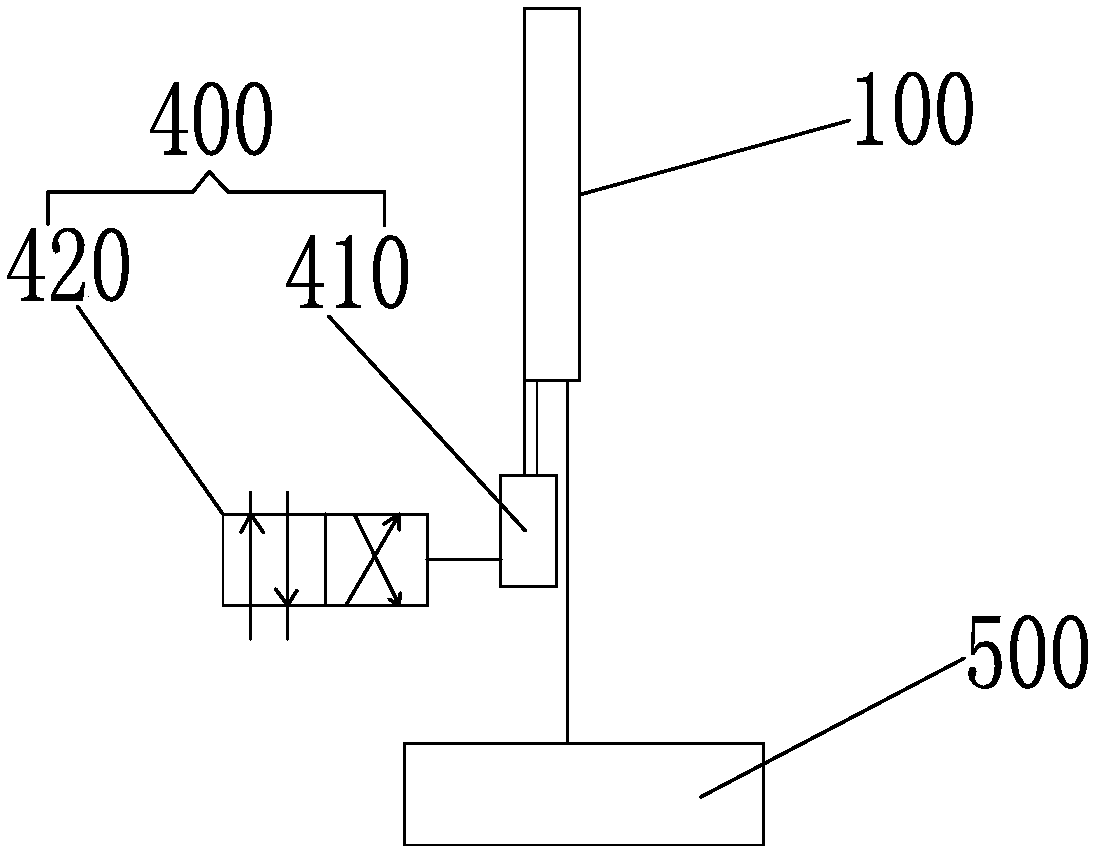

[0035] Such as Figure 1 to Figure 3 As shown, the piece separation mechanism of this embodiment is used to separate the cut piece 10 from the fabric from the fabric;

[0036] Part separation mechanism, including:

[0037] A plurality of support members 100 arranged on the top surface of the receiving platform 20, all support members 100 are arranged in a matrix, and each support member 100 can rise or fall along the vertical direction;

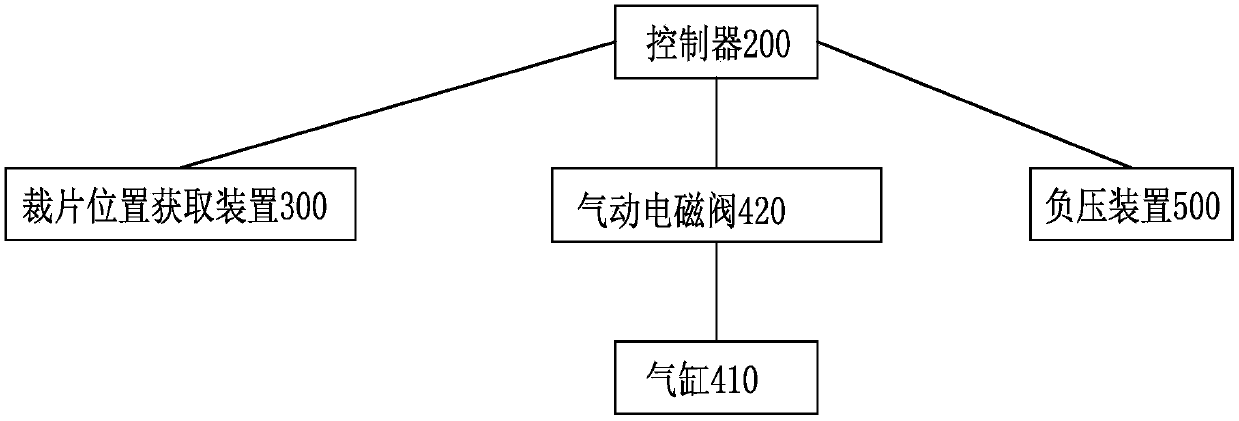

[0038] The controller 200 can separately control each support member 100 to rise or fall along the vertical direction;

[0039] The cutting piece position acquisition device 300 collects the position information of the cutting piece 10 on the receiving table 20, and transmits the position information of the cutting piece 10 to the controller 200; the controller 200 controls the support member 100 directly below the cutting piece 10 Rise or fall along the vertical direction to separate the fabric from the cut piece 10.

[0040] In the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com