Auxiliary brake parking assembly based on vehicle passive safety

A passive safety and auxiliary braking technology, which is applied to vehicle parts, brake components, brakes, etc., can solve the problems of rapid vehicle loss of control, serial car accidents, etc., and achieve the effects of low cost, reduced vehicle damage, and slowed down the forward trend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

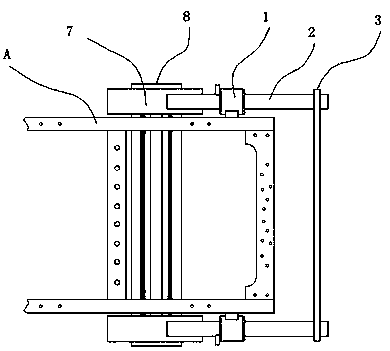

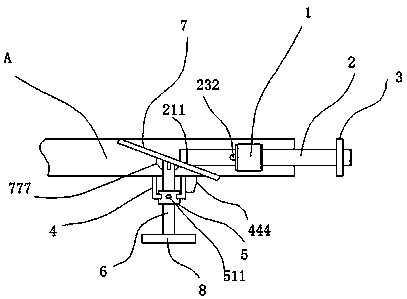

Image

Examples

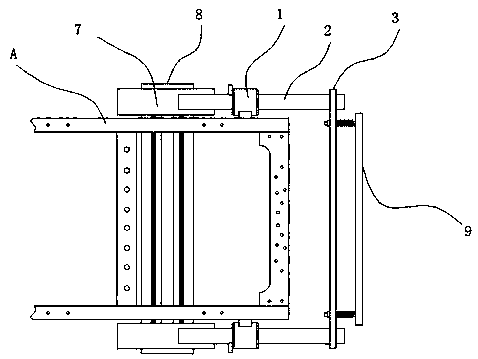

Embodiment 2

[0040] See image 3 with Figure 4 As shown, a laterally movable first plate 9 is provided on the right side of the plate 3, the first plate 9 is parallel to the plate 3, and the first plate 9 also adopts Q235 Material, thickness is 12mm, the left end surface of the first plate 9 is welded with a plurality of rods 901, the rods 901 penetrate the plate 3 to the left and then threadedly connected to the limit nut 902, on the rod 901 A spring 903 with a wire diameter of 4mm is sleeved on the upper part. The spring 903 abuts between the plate 3 and the first plate 9. When the first plate 9 receives a collision force, it compresses the The spring 903 absorbs energy through the compression of the spring 903.

Embodiment 3

[0042] See Figure 5 with Image 6 As shown, a foam board 333 is glued and fixed on the left side of the board 3. Normally, the foam board 333 is not in contact with the first board 9. When the first board moves , And compress the spring. Before the spring is compressed to the limit, the first plate contacts the foam plate, and then the first plate continues to move to the left to absorb energy until the foam plate cannot be compressed. At this time, the first plate The force of the piece acts on the plate, and the foam board and the spring cooperate to achieve double energy absorption and improve the energy absorption effect.

Embodiment 4

[0044] See Figure 7 As shown, a flexible contact plate 999 made of rubber material is glued and fixed on the right side of the first plate 9 and the thickness of the contact plate 999 is 20 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com