Punching device for carrier tape and processing method of punching device

A punching device and carrier tape technology, applied in metal processing and other directions, can solve the problems of inconvenient use of packaging and dislocation of holes during collection, and achieve the effect of facilitating packaging positioning and improving packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

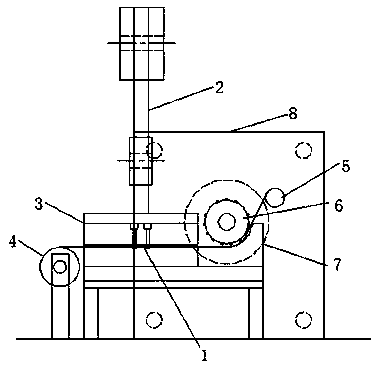

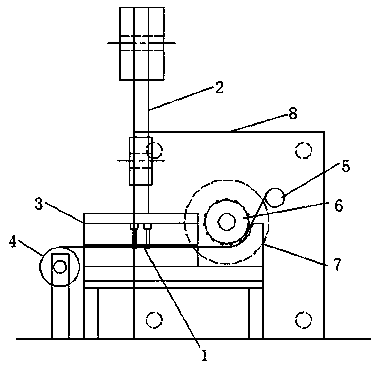

[0020] The technical solutions of the present invention are specifically described below in conjunction with the examples. The present invention discloses a punching device for a carrier tape. figure 1 As shown, it includes a processing table, a punching mechanism 2 arranged above the processing table, a punching die 3 is arranged between the punching mechanism 2 and the processing table, and a punching die 3 is provided for punching Initially determined as the positioning hole. At the same time, it can ensure that the position of the positioning hole of the carrier tape in the Y direction is accurate.

[0021] One side of the processing table is provided with a receiving mechanism, and a positioning and guiding mechanism is arranged between the receiving mechanism and the processing table, and the positioning and guiding mechanism includes a guide block 7 and a surface that cooperates with the guide block 7. Trackwheel6.

[0022] The surface of the guide block 7 is arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com