Cooling system for alloy casting

A cooling system and alloy casting technology, applied in foundry equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of severe fluctuation of alloy melting and casting process parameters, unstable content of alloy elements, affecting the stability of other processes, etc. The effect of homogenization and densification, avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a better understanding of the present invention by showing examples of the present invention.

[0012] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

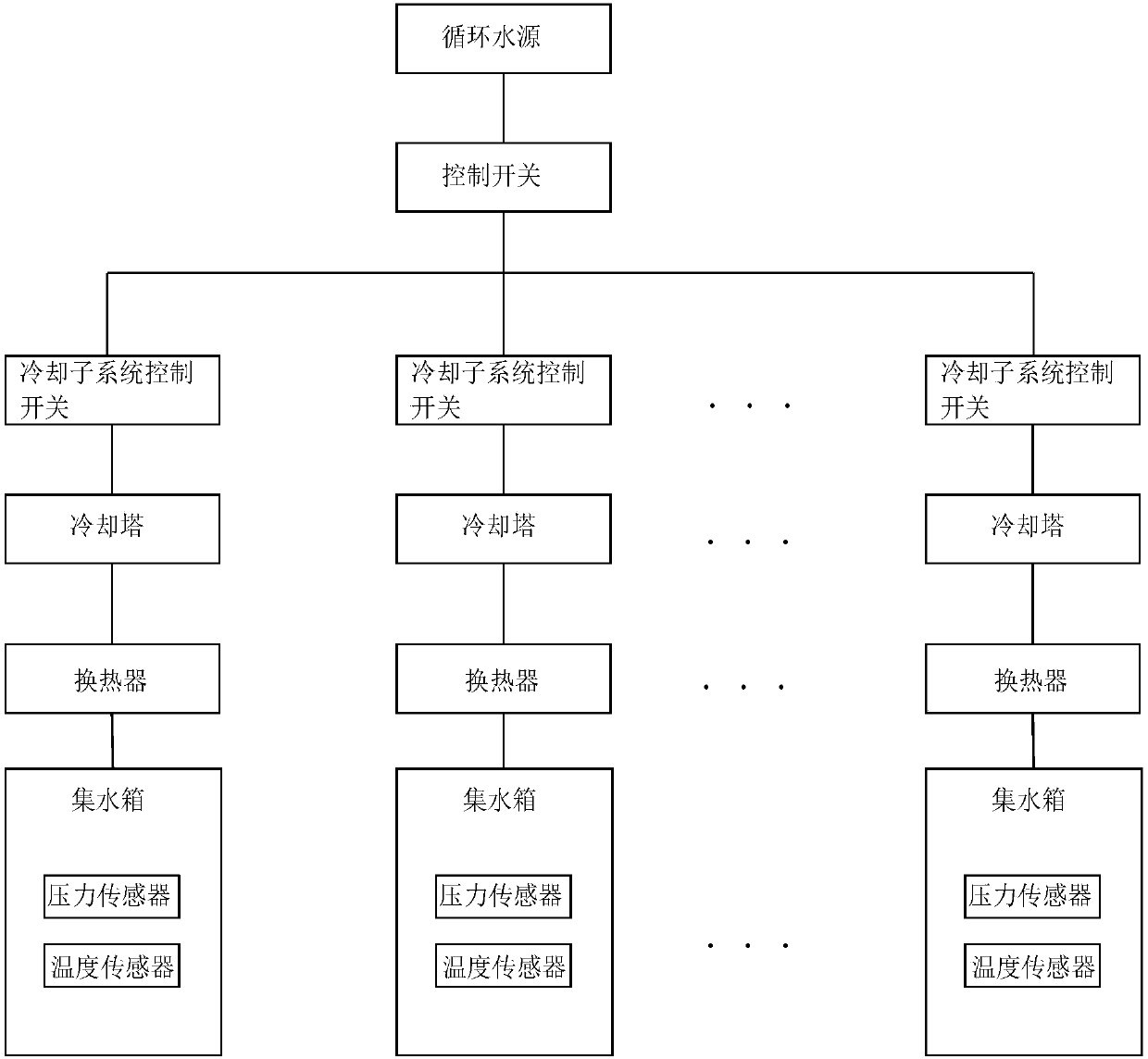

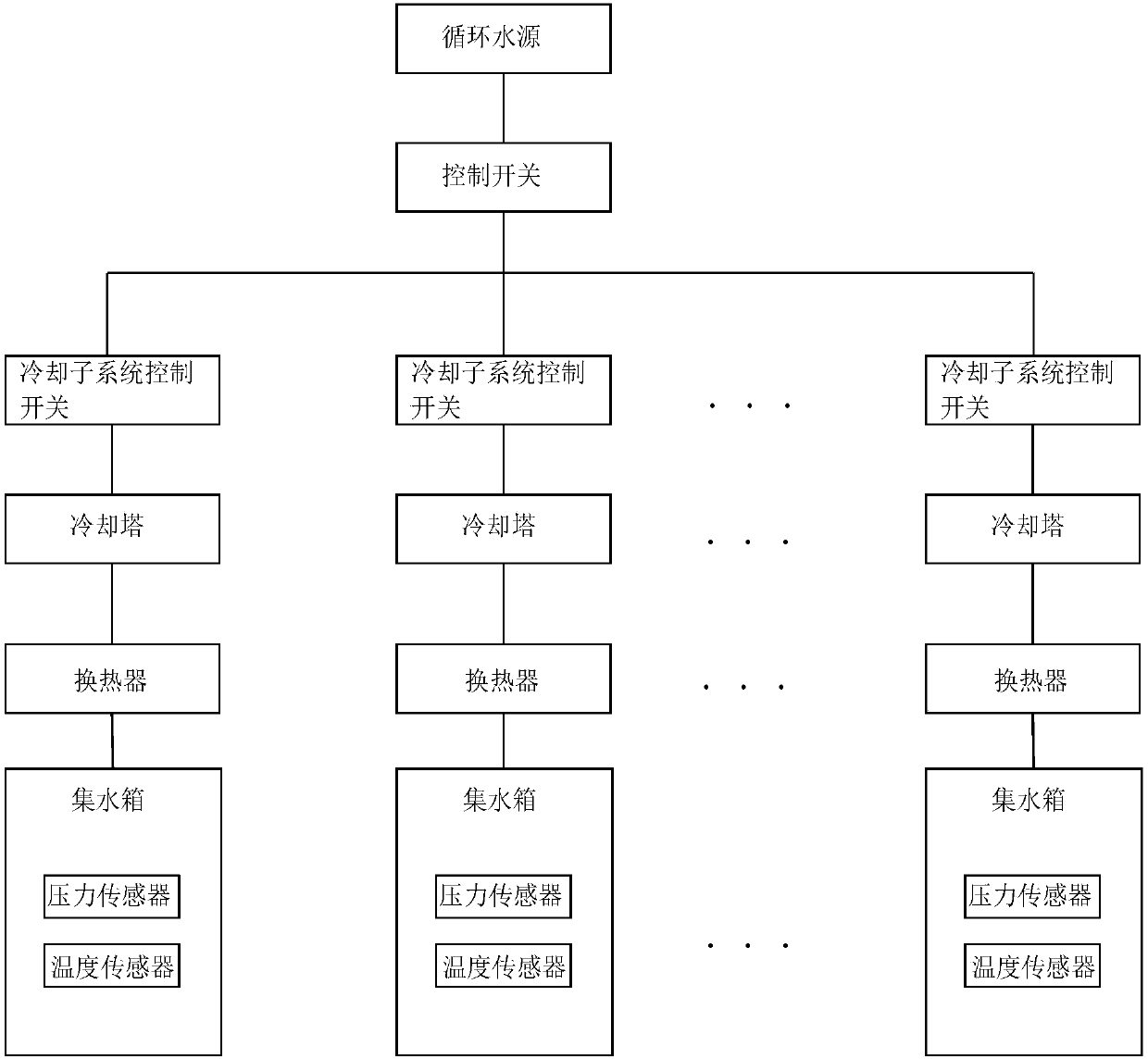

[0013] Such as figure 1 As shown, the present invention provides a cooling system for alloy casting, including: a circulating water source, a cooling tower, a heat exchanger, a sensor unit, a water collection tank, and a control switch; the circulating water source is connected to the control switch; the cooling tower It is connected with the heat exchanger; the heat exchanger is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com