A magnetic circuit structure of a double-V permanent magnet hub motor

A technology of in-wheel motor and permanent magnet is applied in the field of magnetic circuit structure of double-V-type permanent magnet in-wheel motor, which can solve the problems of less research and application, and achieve the effect of strengthening heat dissipation effect, small magnetic leakage coefficient and reducing core loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

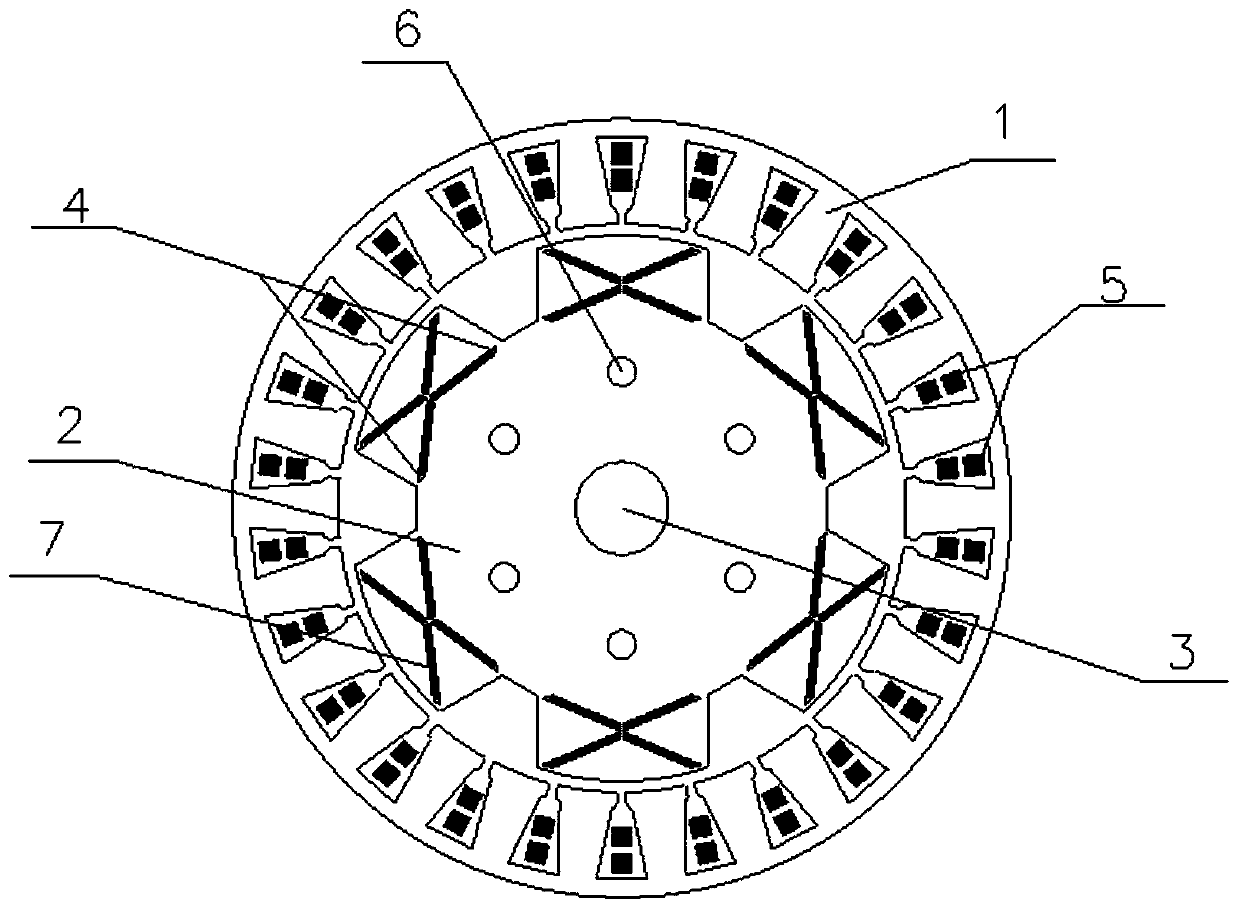

[0015] Such as figure 1 As shown, this embodiment provides a double V-shaped permanent magnet hub motor magnetic circuit structure, including a stator 1, a rotor 2, a rotor shaft 3, a winding slot 5 and a permanent magnet 7; the rotor 2 is arranged inside the stator 1 And the rotor 2 is arranged coaxially with the stator 1, the rotor shaft 3 is arranged at the center of the rotor 2, the winding slot 5 is arranged on the inner wall of the stator 1, and the permanent magnet 7 set on the rotor 2.

[0016] In this specific embodiment, the outer wall of the rotor 2 is provided with a plurality of rotor teeth. Four permanent magnets 7 are arranged on each rotor tooth, and the permanent magnets on each rotor tooth are distributed in an X shape. It also includes a magnetic isolation bridge 4, and the magnetic isolation bridge 4 is arranged at the root of the rotor teeth. Six ventilation holes 6 are uniformly arranged on the rotor 2 along the circumferential direction.

[0017] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com