Hydrogenation rate control method and hydrogenation machine

A technology of rate control and hydrogenation machine, applied in the field of hydrogenation machine, can solve the problems of high cost and complicated control system, and achieve the effect of low implementation cost and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

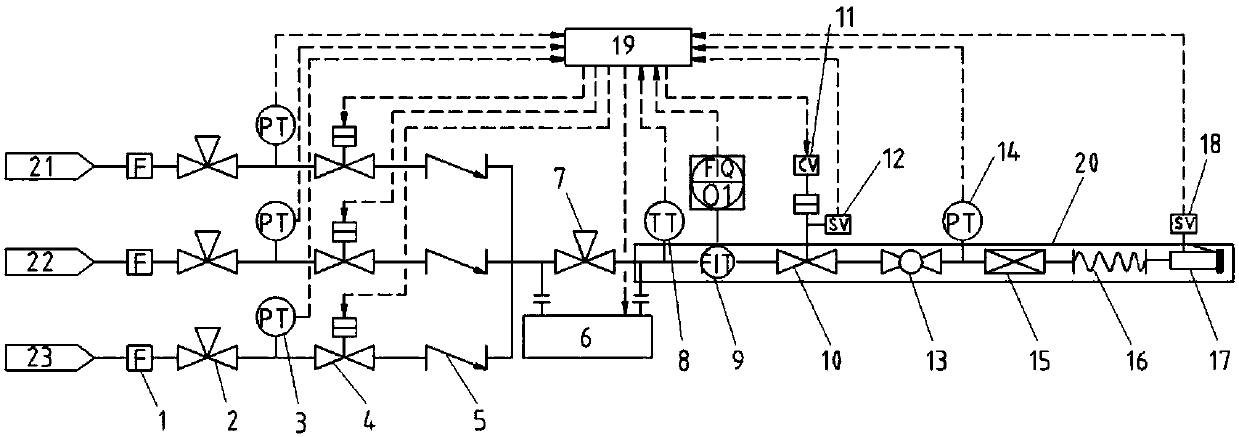

[0032] Embodiment 1 of the hydrogenation machine of the present invention is as figure 1 As shown, it includes a hydrogen storage tank and a hydrogenation gun 17, and also includes a control system 19 that controls the hydrogenation rate according to the ratio of the pressure of the vehicle hydrogen bottle to the temperature change value within the set time. Different high-pressure hydrogen storage tanks 21, medium-pressure hydrogen storage tanks 22, and low-pressure hydrogen storage tanks 23 are connected through a pipeline system between the hydrogen storage tanks and the hydrogenation gun 17. The pipeline system includes a high-pressure hydrogen storage tank 21, a medium-pressure hydrogen storage tank The pressure hydrogen storage tank 22 and the low-pressure hydrogen storage tank 23 respectively lead to the shunt pipeline of the confluence point and the main pipeline connected to the hydrogenation gun 17 from the confluence point. The high-pressure hydrogen storage tank 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com