Pre-tightening type bolt connecting assembly for ultra-large compressor spindle connection

A technology for connecting components and compressors, applied in the direction of shrinkage connection, connecting components, threaded fasteners, etc., can solve problems such as mechanical damage, scraping between rotor and stator, and achieve the effect of eliminating static deflection and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

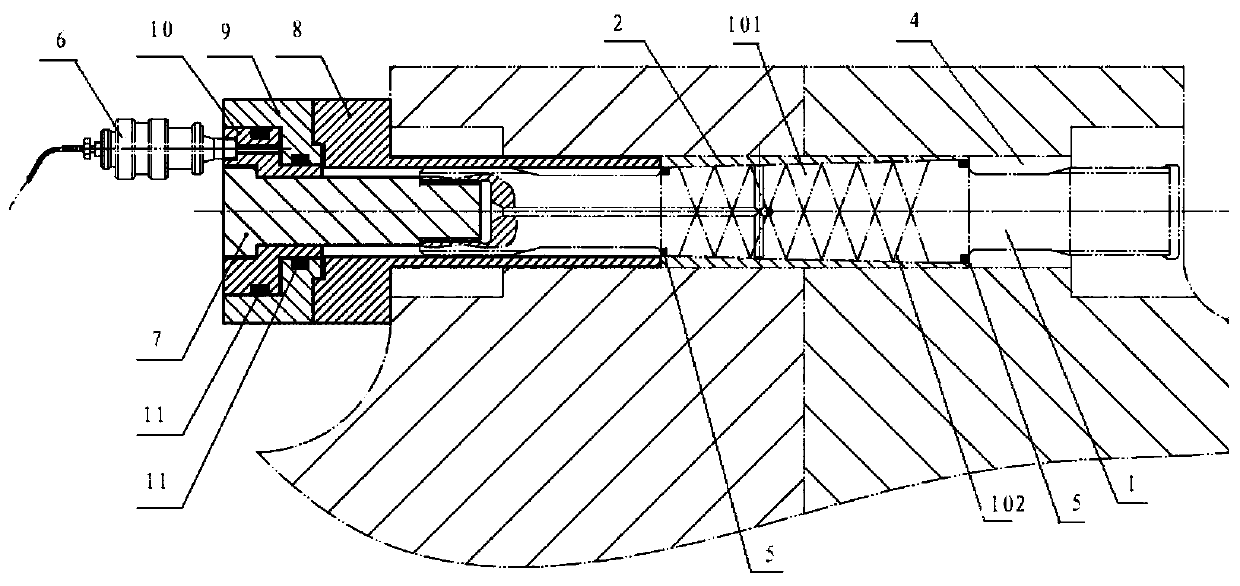

[0026] Such as figure 1 As shown, a pre-tightened bolt connection assembly suitable for connecting the main shaft of an ultra-large compressor includes a bolt mechanism and a disassembly mechanism; the bolt mechanism includes a screw 1, a bush 2 set in the middle of the screw 1, and a The nut 3 with detachable connection at both ends, the bushing 2 is set on the screw 1 in a truncated cone shape coaxial with the center line of the screw 1, and the radius of one end surface of the bushing 2 is not greater than the radius of the main shaft connection hole 4, the bushing The radius of the other end surface of 2 is greater than the radius of the main shaft connecting hole 4; the disassembly mechanism is detachably connected with one end of the screw 1, and the disassembly mechanism is used to move the screw 1 axially in the main shaft connection hole 4 to complete the bolt on the main shaft. Assembly and disassembly in hole 4.

[0027] In this embodiment, the bushing 2 is fitted ...

Embodiment 2

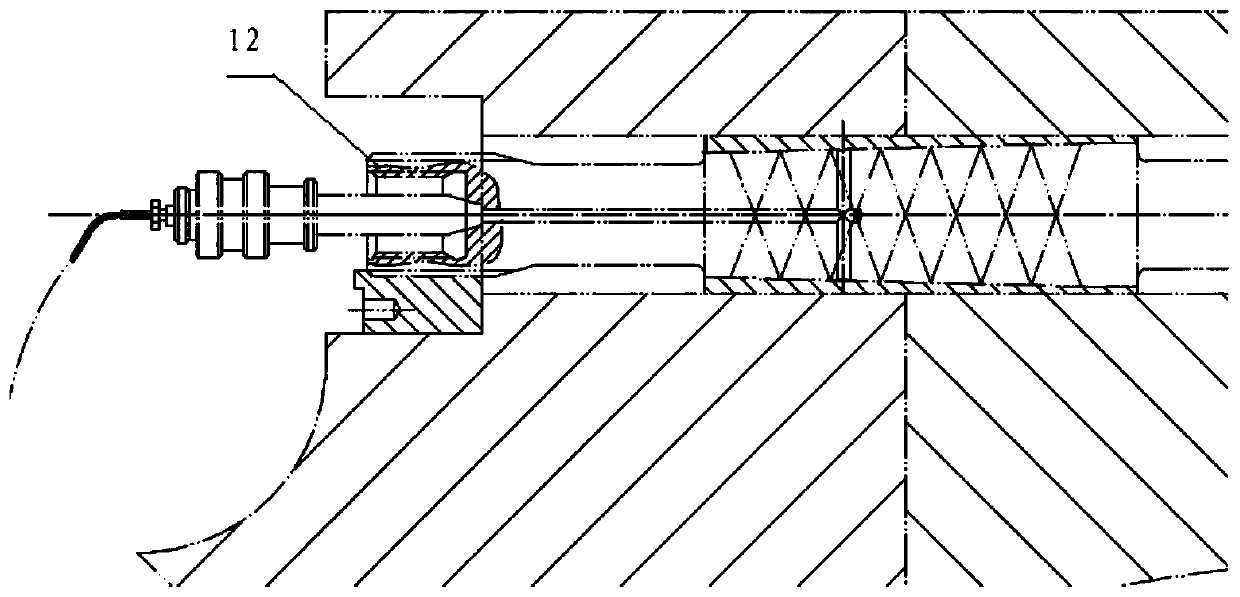

[0042] Referring to Embodiment 1, the difference between the pre-tightened bolted connection assembly provided in this embodiment is that, as figure 2 As shown, the assembly and disassembly mechanism also includes connectors 12 that can be connected to the screw rod 1 and the high-pressure oil pump 6 at both ends.

[0043] The usage method of the bolted connection assembly of the present embodiment is as follows:

[0044] (1) Connect one end of the connector 12 to one end of the screw 1 assembled in the main shaft connecting hole 4, and then connect the other end of the connector 12 to the high-pressure oil pump 6;

[0045] (2) Fill the bolt connection assembly with oil pressure through the high-pressure oil pump 6, stretch the screw rod 1, and the operating pressure must be greater than the oil pressure during installation;

[0046] (3) Unscrew the nut 3, release the oil pressure, and then take off the connector 12 to complete the disassembly of the screw 1 in the main shaf...

Embodiment 3

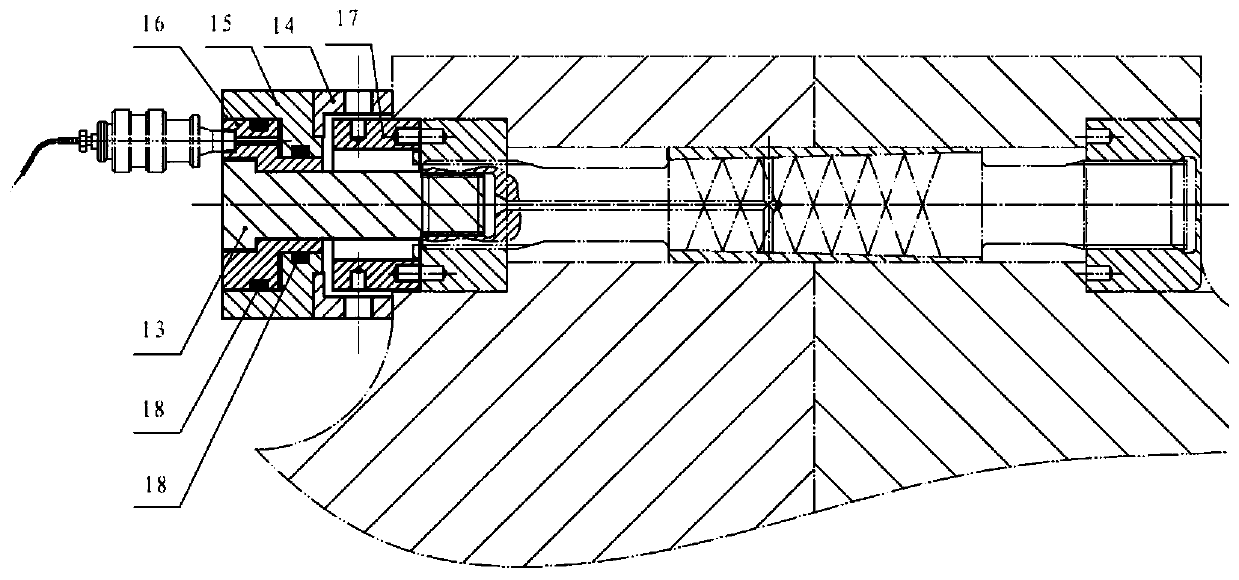

[0048] Referring to Embodiment 2, the difference between the pre-tightened bolted connection assembly provided in this embodiment is that, as image 3 As shown, the dismounting mechanism also includes a nut dismounting unit. The nut dismounting unit includes a second connecting rod 13 detachably connected to the nut 3 at one end, and a support sleeve 14 and a second cylinder that are sequentially sleeved on the outside of the second connecting rod 13. body 15 and the second piston 16 , and the end of the support sleeve 14 away from the second cylinder body 15 is detachably connected to the nut 3 through the connecting sleeve 17 .

[0049] As a preferred embodiment, a third O-ring 18 is provided on the contact surface between the second cylinder 15 and the second piston 16 .

[0050] The usage method of the bolted connection assembly of the present embodiment is as follows:

[0051] (1) The second connecting rod 13 is connected with the nut 3 through the connecting sleeve 17; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com