Novel compressed air energy storage system

A technology of compressed air energy storage and storage system, which is applied in the direction of steam engine device, liquid variable displacement machinery, variable displacement pump components, etc. It can solve the problems of long external work time, pressure loss of pressure reducing valve, long sustainable time, etc. , to achieve the effect of reducing the difficulty of production technology, reducing the loss of pressure energy and improving the working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

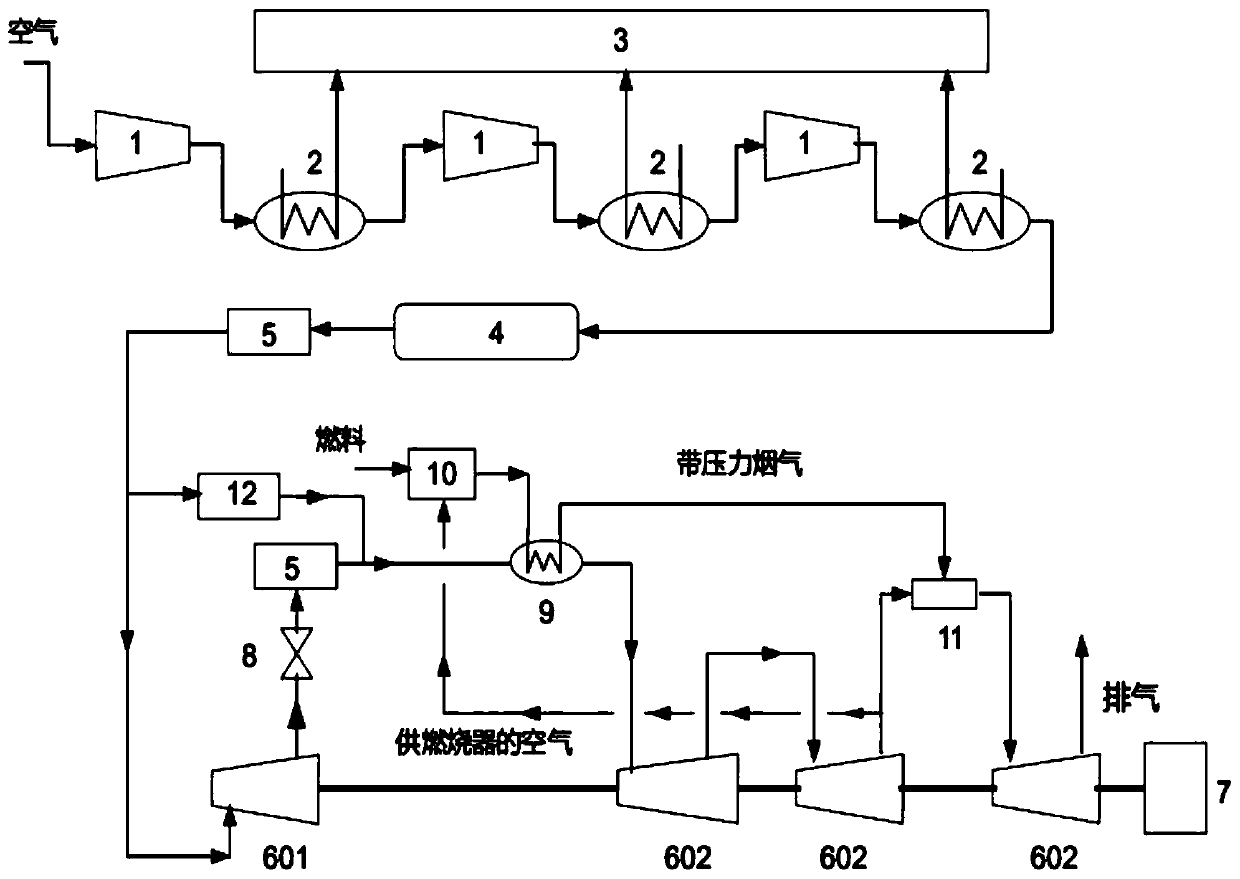

[0040] This embodiment can be used not only in the peak-shaving and valley-filling scenarios of the power grid, but also in the large-scale storage and release of new energy such as photovoltaic power generation or wind power. see figure 1 , the electric energy storage process, the electric energy is used to drive the multi-stage air compression unit 1 to do work to prepare high-pressure compressed air, store the high-pressure compressed air in the air storage space 4, and the compressed air discharged from the air compression unit 1 passes through the heat exchanger 1 and 2 for cooling, and then enter the next air compression unit 1 to compress to further increase the pressure of the output air. After being pressurized by multiple air compression units 1, the air can be compressed from the normal pressure state to the required high pressure state . During the preparation process of high-pressure air, the heat exchanger 12 transfers the heat carried by the air to the heat exc...

Embodiment 2

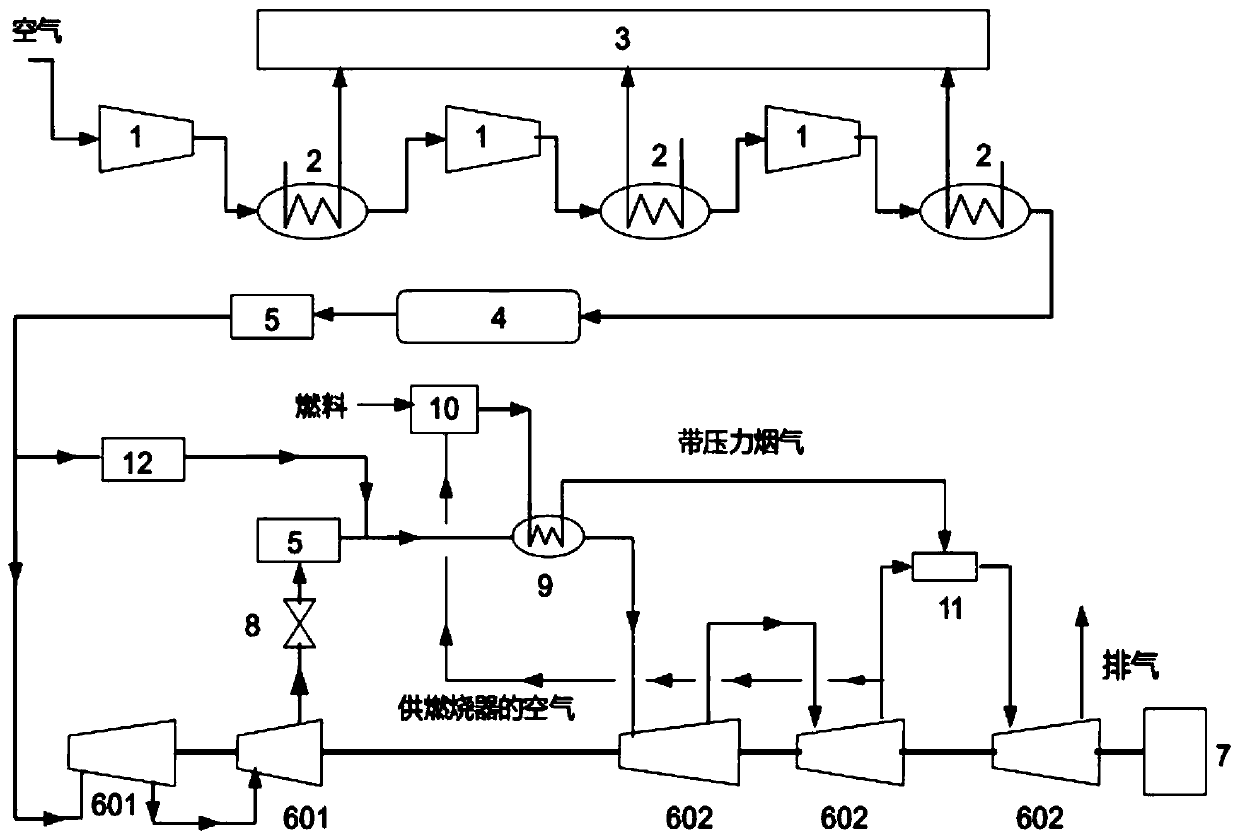

[0049] This embodiment can be used not only in the peak-shaving and valley-filling scenarios of the power grid, but also in the large-scale storage and release of new energy such as photovoltaic power generation or wind power. see figure 2 , the difference from Embodiment 1 is that two first expansion units 601 are arranged before the back pressure valve 8, and the pressurized air required for combustion of the burner 10 comes from the pressurized exhaust gas of the second second expansion unit 602.

[0050] The back pressure valve 8 is set at the exhaust port of the second first expansion unit 601, so that the first expansion unit 601 has the sliding pressure operation ability to adapt to the real-time drop of the air pressure in the air storage space 4, and also maintains the second first expansion unit 601. The stability of the exhaust pressure of the expansion unit 601 allows the first, second and third second expansion units 602 connected after the back pressure valve 8 ...

Embodiment 3

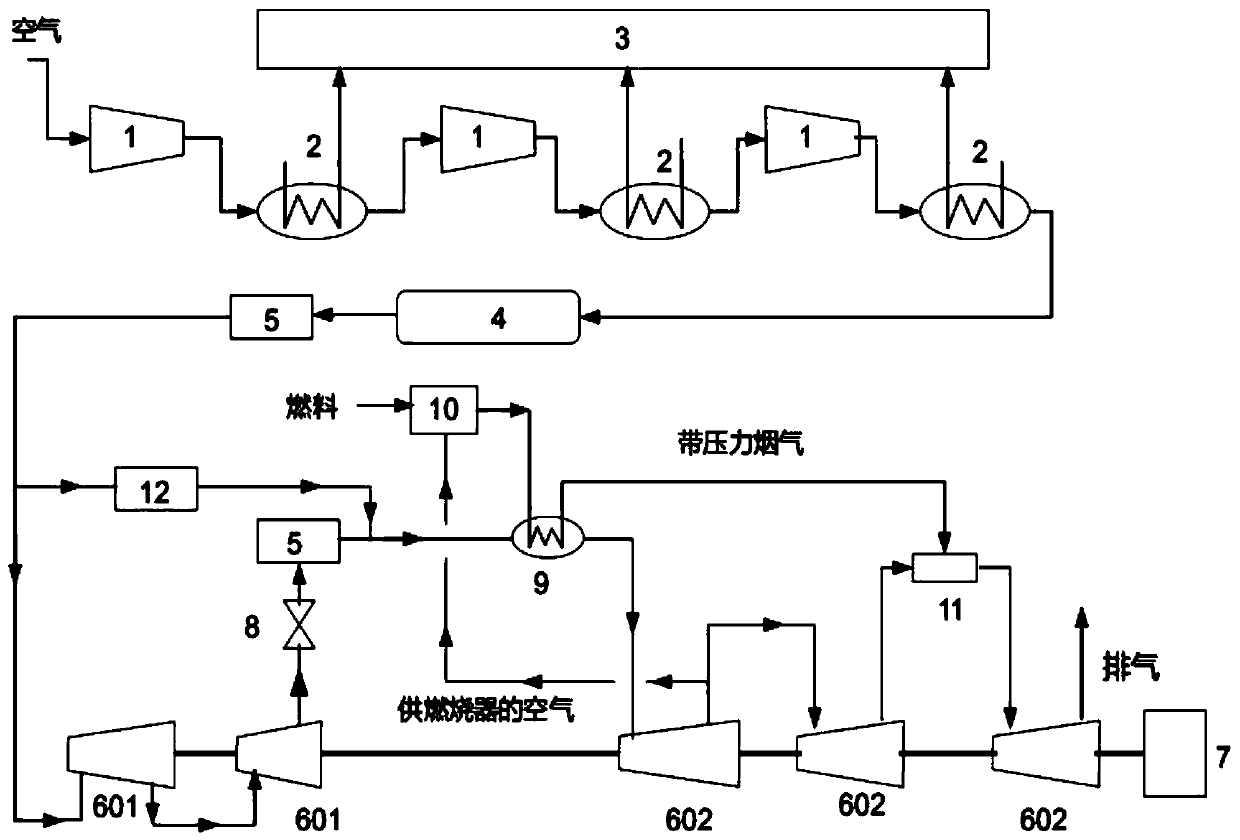

[0052] This embodiment can be used not only in the peak-shaving and valley-filling scenarios of the power grid, but also in the large-scale storage and release of new energy such as photovoltaic power generation or wind power. see image 3 , and the difference from the second embodiment, the combustion air required by the burner 10 is exhausted from the first and second expansion units 602 .

[0053] The back pressure valve 8 is set at the exhaust port of the second first expansion unit 601, so that the first and second first expansion unit 601 have the sliding pressure operation ability to adapt to the real-time drop of the air pressure in the gas storage space 4, and at the same time The stability of the exhaust pressure of the second first expansion unit 601 is maintained, so that the first, second and third second expansion units 602 connected after the back pressure valve 8 can all operate at the set stable pressure parameters to run.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com