Multi-station elbow correction system and method for producing spiral lamp tube

A calibration system, multi-station technology, applied in manufacturing tools, glass molding, glass remolding, etc., can solve the problems of lack of spiral lamp calibration device, single production method of spiral lamp, and effective guarantee, etc. To achieve the effect of improving heating and setting efficiency, high production efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

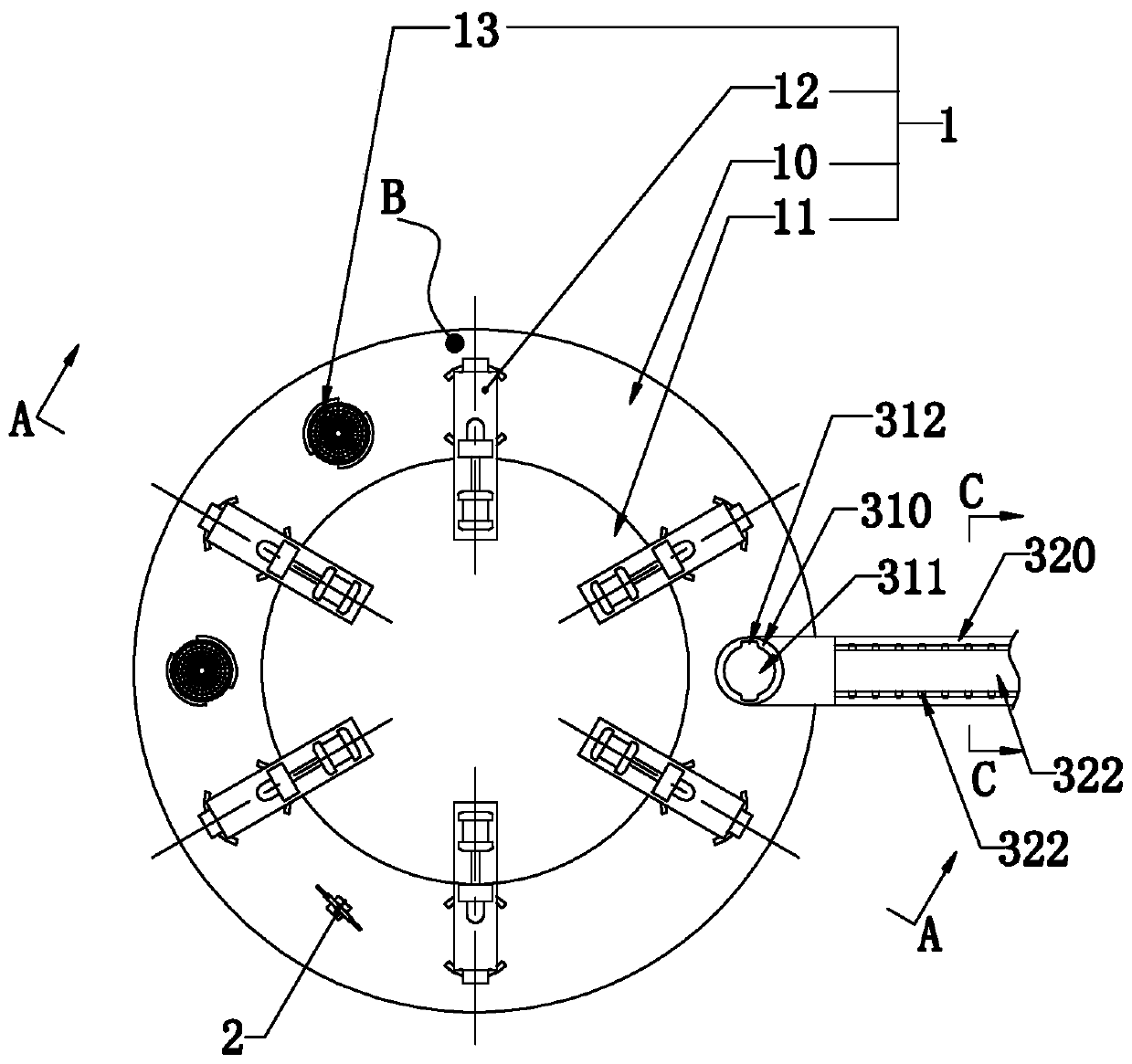

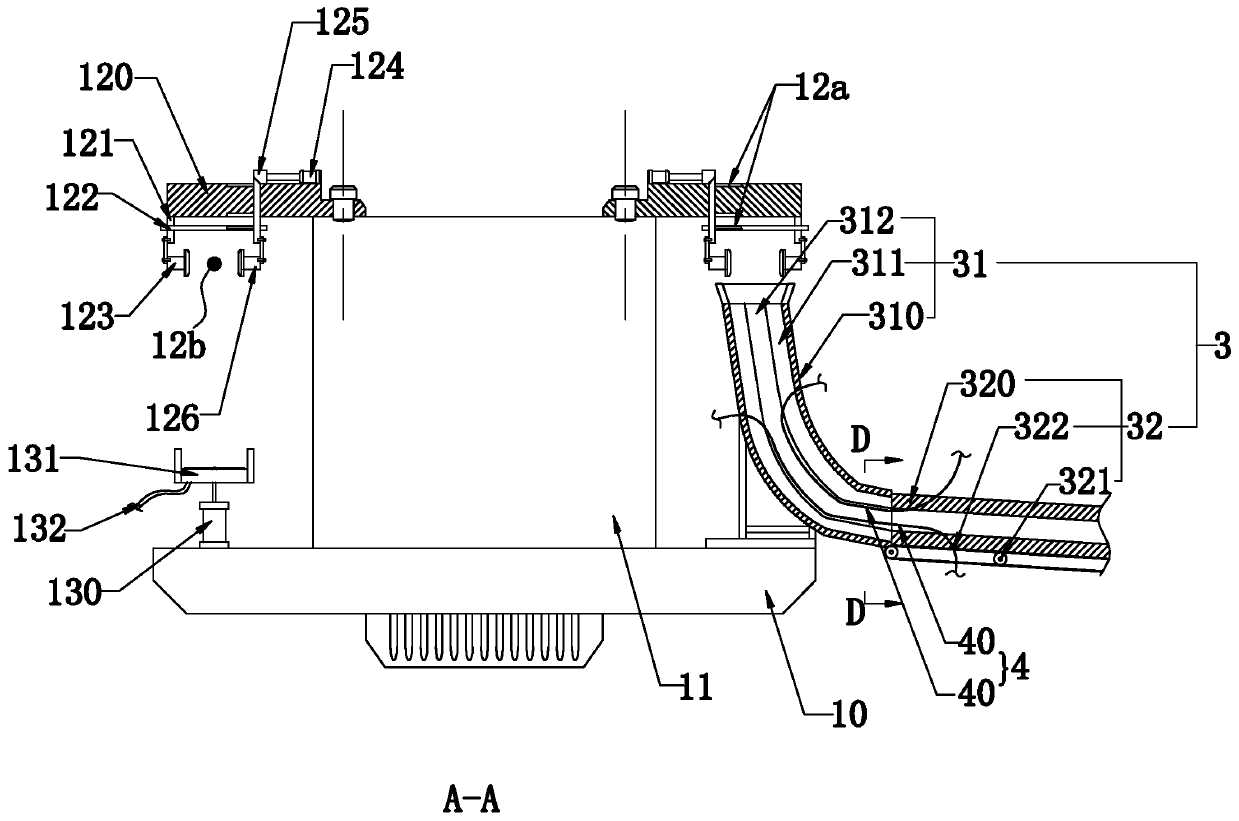

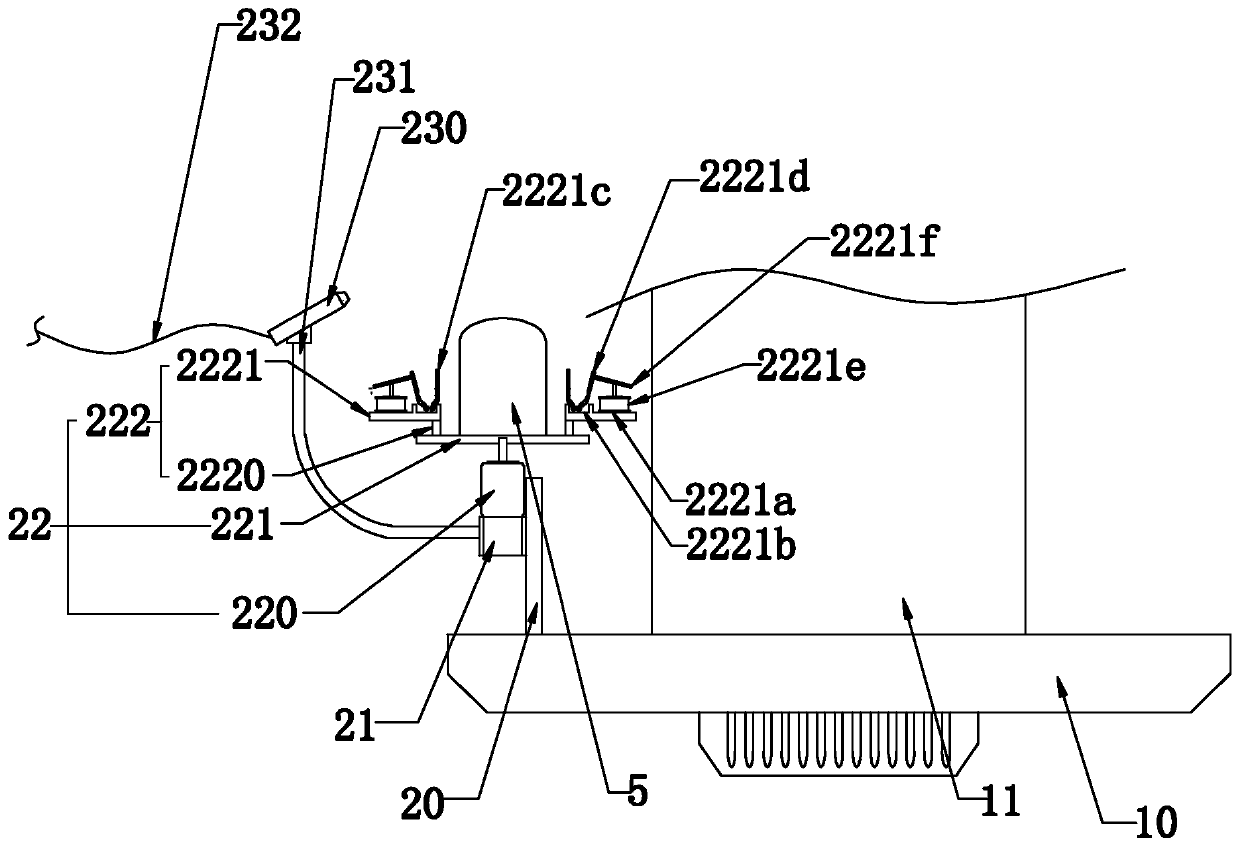

[0028] Such as Figure 1 to Figure 5 As shown, the present invention discloses a multi-station bent tube correction system for producing spiral lamp tubes, including a melting device for softening straight lamp tubes and a spiral mold for shaping straight lamp tubes into spiral lamp tubes. In the specific embodiment of the invention, it includes a rotary transport assembly 1 for receiving the spiral lamp tube from the spiral mold, which is arranged on the rotary transport assembly 1 and is used to shape the spiral lamp tube and realize the adjustment of the free end of the spiral lamp tube. The bent correcting component 2 and the correcting component 3 arranged at the output end of the rotary transport component 1 .

[0029]In a specific embodiment of the present invention, the rotary material conveying assembly 1 includes a supporting chassis 10, a material conveying turntable 11 arranged on the supporting chassis 10 and capable of rotating in the axial direction, and several...

Embodiment 2

[0056] A multi-station bend correction method for producing spiral lamp tubes, in a specific embodiment of the present invention, includes the following steps:

[0057]S1 Straight hose melting: Put the prepared straight hose into the melting device for softening for 1 minute, then take it out, and shape the softened straight hose through a spiral mold to form a spiral lamp embryo;

[0058] S2 spiral lamp correction and finalization: the clamping device on the rotary feeding assembly receives the spiral lamp embryos, and sends the spiral lamp embryos to the area where the correction assembly is located from the direction of rotation of the feeding turntable, then stops, and the lifting cylinder drives the first The clamping block and the second clamping block move to just below the free end of the spiral lamp tube embryo, and then, the spiral lamp tube embryo is heated by the flame spraying device so that the free end softens and falls on the first clamping block and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com