Vacuum heating shaping device for shoe-making production

A technology of vacuum heating and vacuum shaping, which is applied to shoemaking machinery, shoe uppers, footwear, etc. It can solve the problems of slowing down production efficiency, bulky size, and low heating and shaping efficiency of shoes, so as to improve shaping efficiency and production efficiency , improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

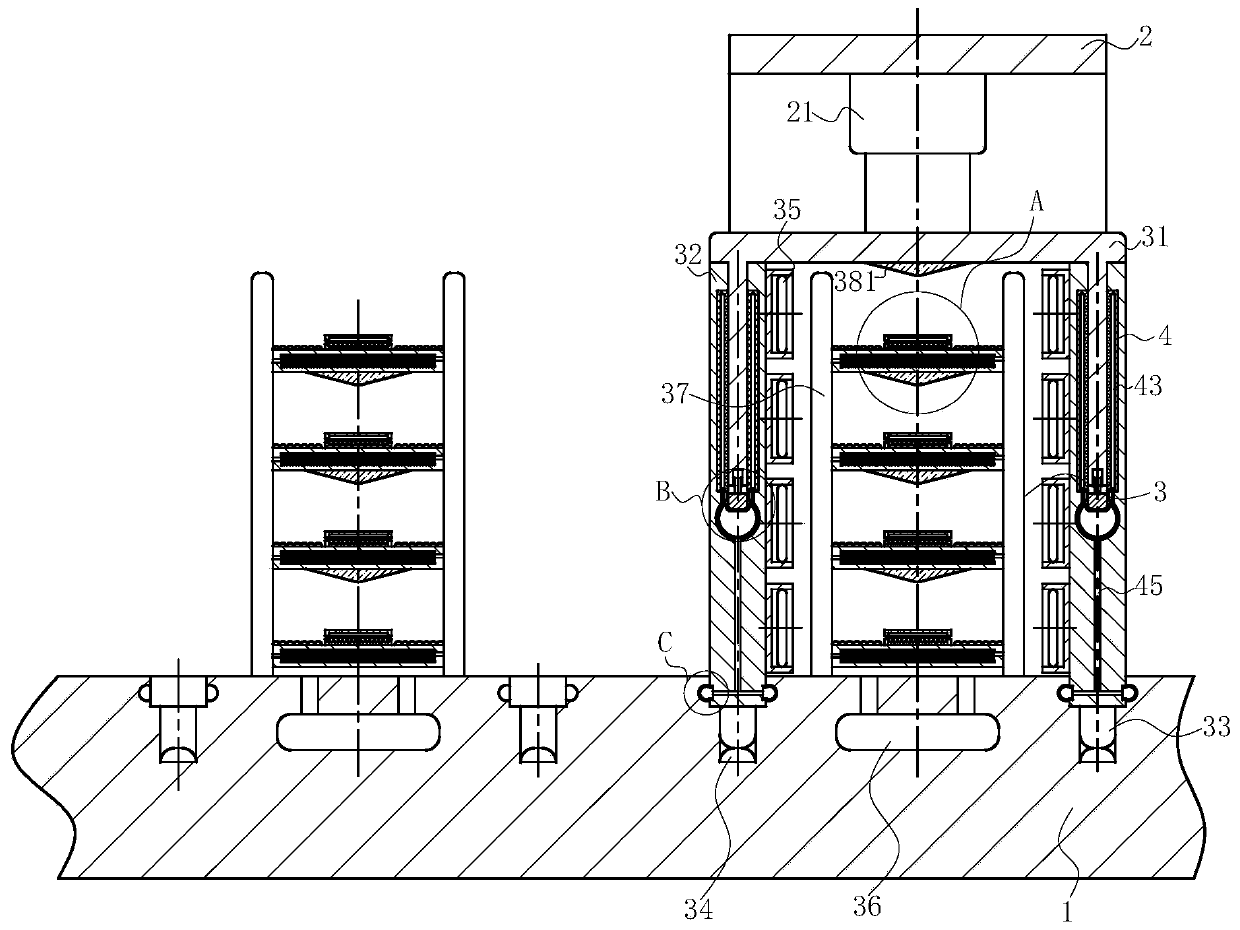

[0019] use Figure 1-Figure 4 A vacuum heating and shaping equipment for shoemaking production according to an embodiment of the present invention is described as follows.

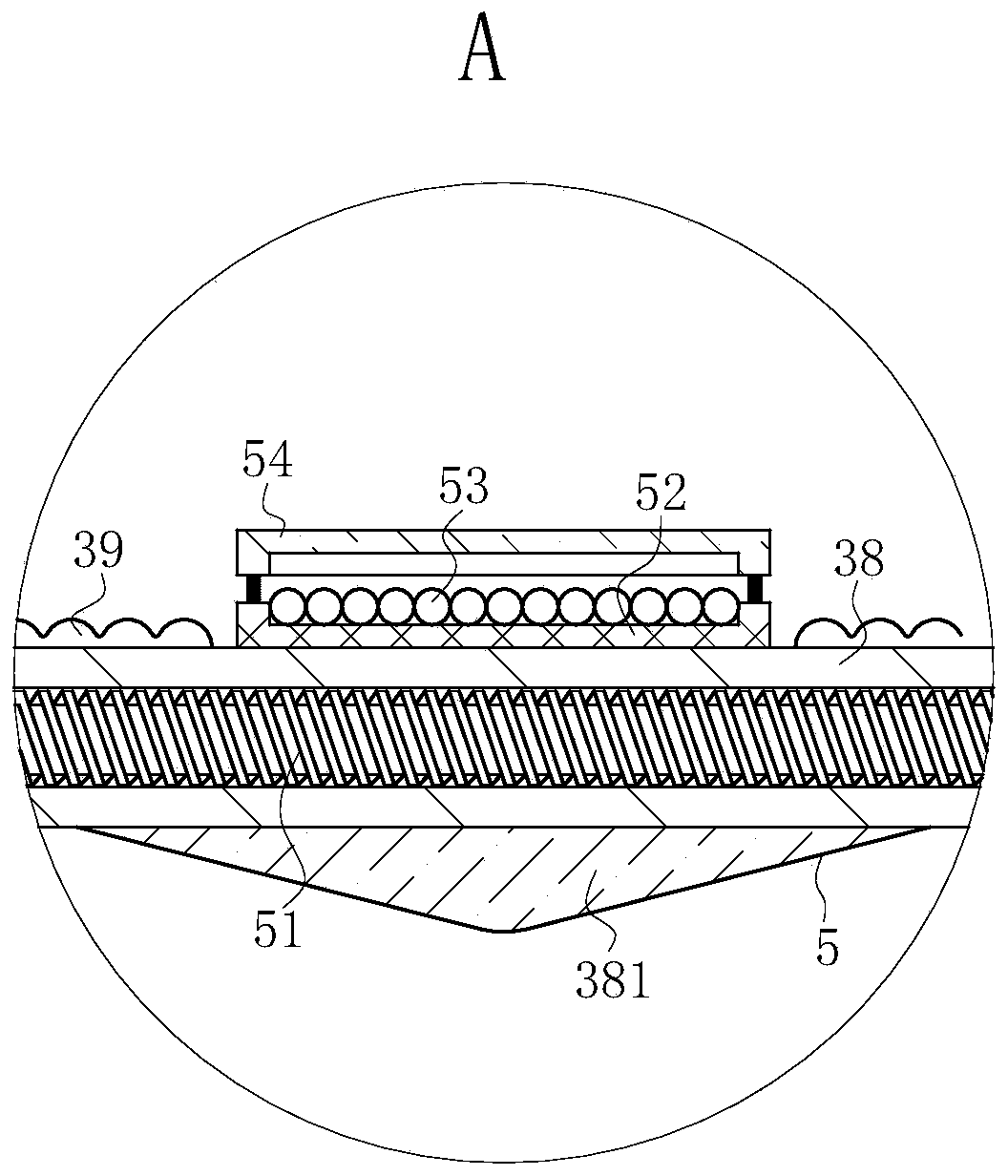

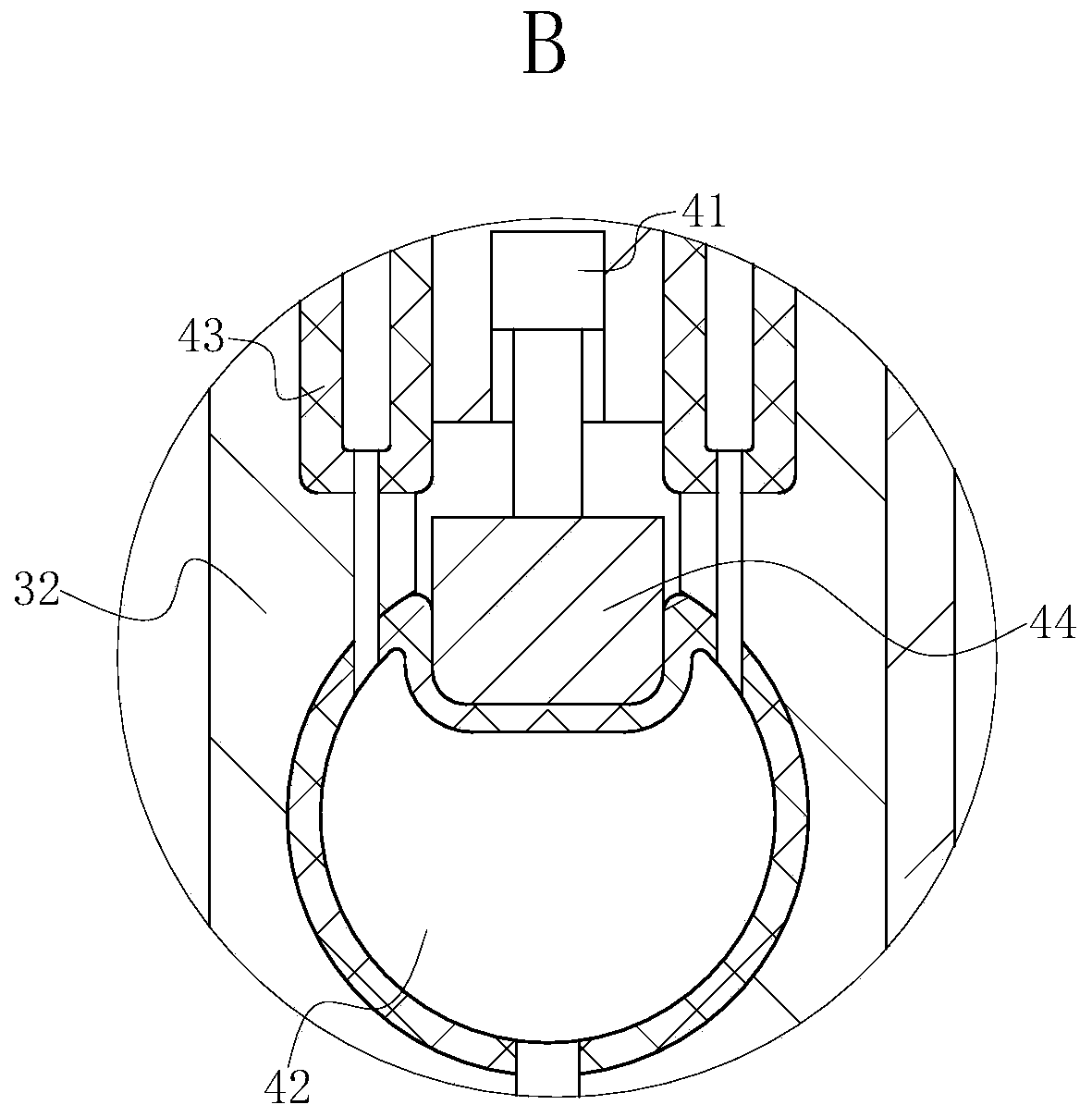

[0020] Such as Figure 1-Figure 4As shown, a vacuum heating and sizing equipment for shoemaking production according to the present invention includes a conveying plate 1, a No. 1 installation frame 2, a vacuum sizing mechanism 3, a sealing mechanism 4 and a support mechanism 5; the No. 1 installation The frame 2 is concave, and the No. 1 mounting frame 2 is arranged on the front and rear sides of the conveying plate 1. The upper and lower surfaces of the No. 1 mounting frame 2 are fixedly connected with a No. 1 electric telescopic rod 21; the lower end of the No. 1 electric telescopic rod 21 is provided with a vacuum setting Mechanism 3; the vacuum setting mechanism 3 includes a sliding cover 31, a closing frame 32, a No. 1 contact 33, a No. 2 contact 34, a heating lamp 35, a vacuum pump 36, a No. 2 moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com