Hoisting process for general section of warehouse deck of orange juice ship

An orange juice boat and deck technology, which is applied to the hull deck, hull, and boat parts, etc., can solve the problems of difficult construction by workers, large cross-construction surface, and narrow construction space, and achieves the effect of no margin hoisting and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

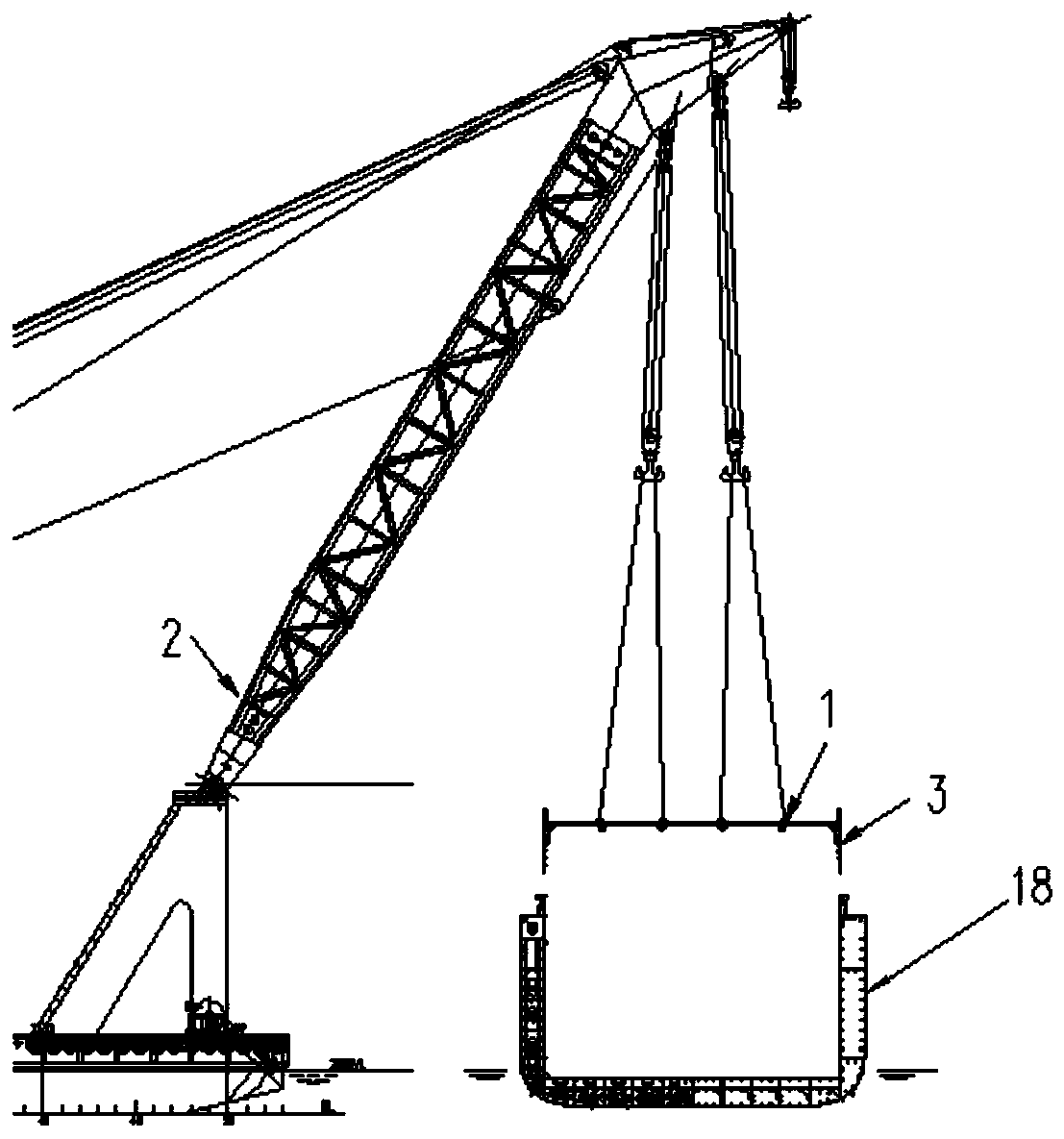

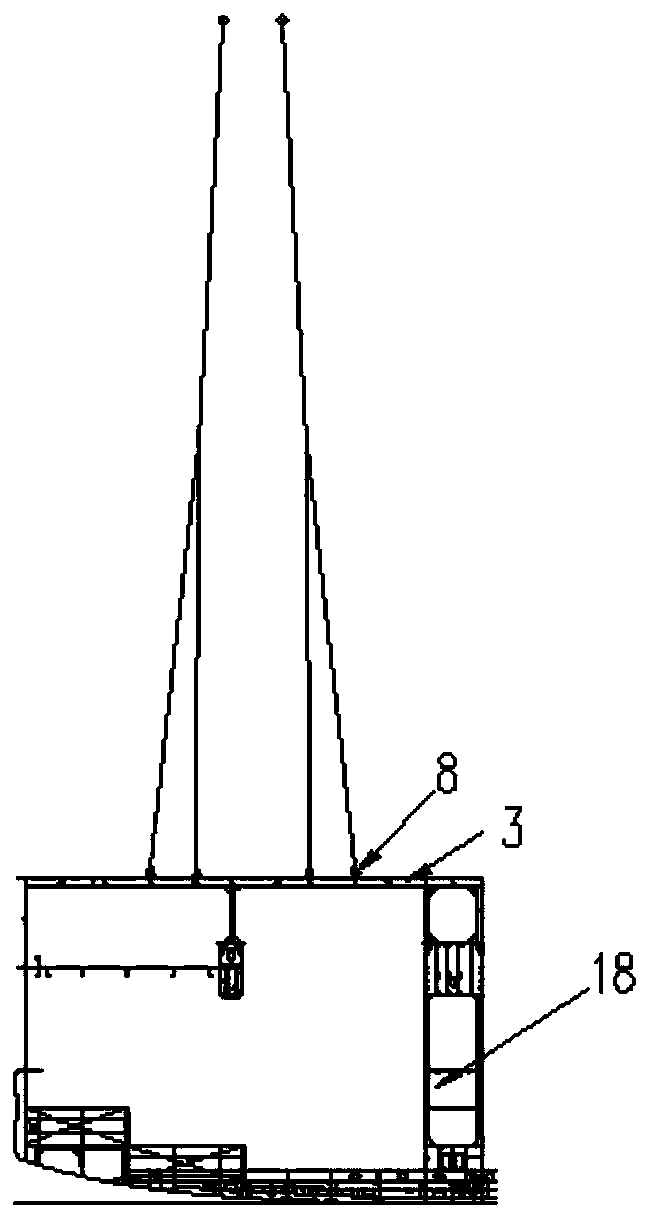

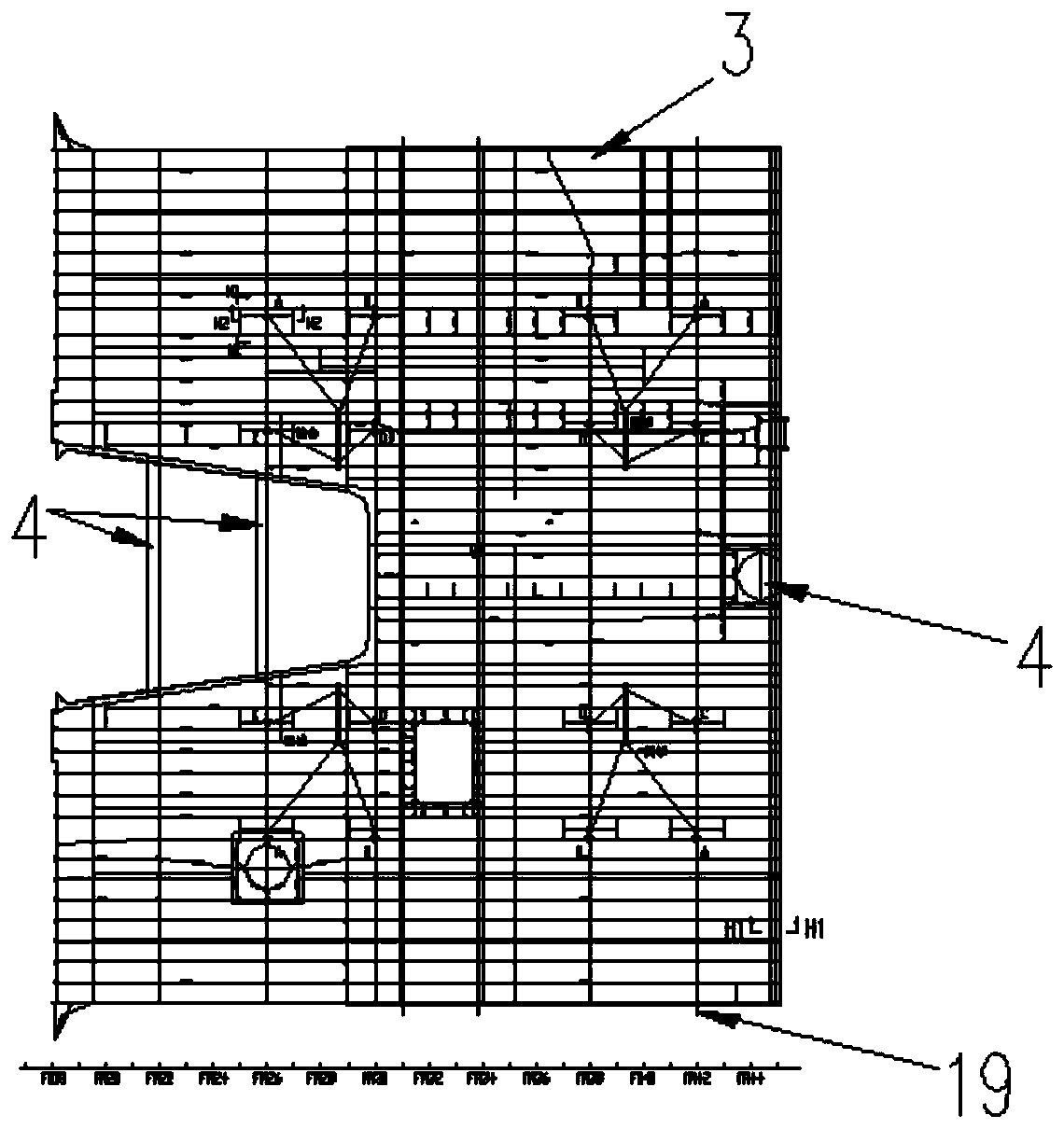

[0086] The present invention is the hoisting process of the general section of the cargo warehouse deck of an orange juice ship, such as Figure 1 to Figure 45 shown and Figure 54 as shown ( image 3 Among them, the floating crane of the first deck section adopts 8 60-meter steel wire ropes and 4 steel wire rings with a circumference of 2 meters, all of which are folded in half, and the allowable load is 50t; 8 55-ton shackles and 16 35-ton shackles. There are 16 D-40B lifting lugs, arranged horizontally; the lifting lugs and their reinforcements are deeply welded with the hull structure, and color inspection is done. Figure 4 Among them, the floating crane of the second deck section adopts 8 steel wire ropes of 60 meters and 4 steel wire rings with a circumference of 2 meters, all of which are folded in half, and the allowable load is 50t; Figure 5 Among them, the floating crane of the third deck section uses 8 60-meter steel wire ropes and 4 steel wire rings with a circ...

Embodiment 2

[0118] The difference from Embodiment 1 is that, as Figure 46 As shown, in the S1 step, during the process of cutting the cargo hold deck into six deck segments 3, several sub-notches 9 smaller than the notches are processed on the deck segment 3 where notches need to be processed. , the part between the adjacent sub-notches 9 is cut off after the hoisting is completed as the reinforcement 10 .

Embodiment 3

[0120] The difference from Embodiment 1 is that, as Figure 47 As shown, in step S6, the hatch 11 is simultaneously cut out during the hoisting and lowering process of the deck segment 3; the cutting knife 12 is fixedly arranged on the bottom wall of the bulkhead below the hatch 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com