Method for manufacturing spar cap for wind turbine blade

A technology of wind turbine blades and spar caps, which is applied in the field of wind turbine manufacturing, can solve the problems of resin inability to flow, weak mechanical structure, and weak bonding, etc., and achieve the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

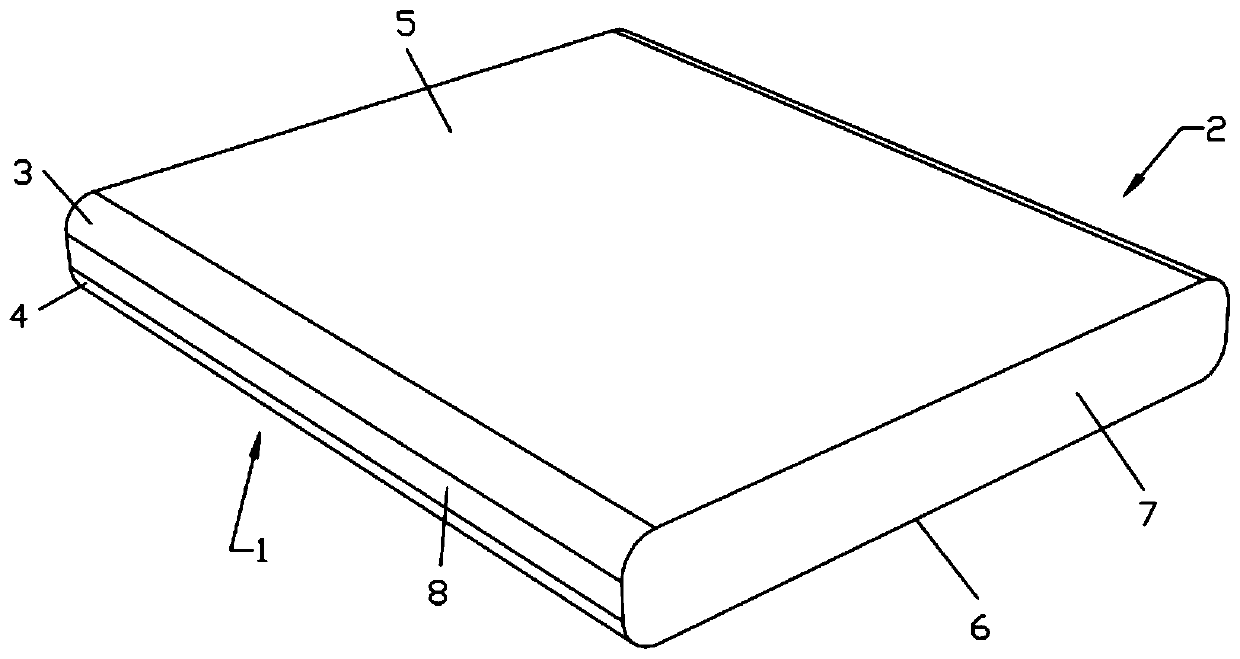

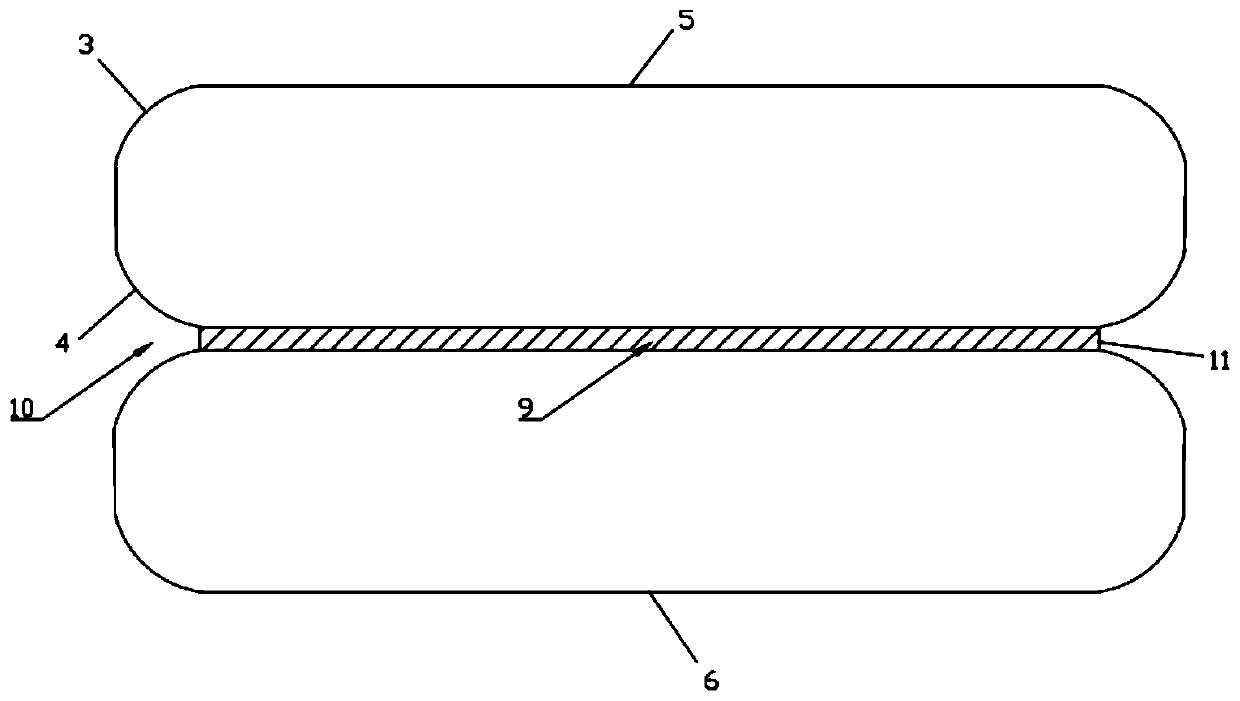

[0023] Such as Figure 1-2 Shown, be a kind of method of manufacturing the spar cap that is used for wind turbine blade of the present invention, comprise the steps:

[0024] S1. Provide a plurality of pultruded fiber sheets, each fiber sheet has a first side 1 and a second side 2 that are opposite to each other and extend longitudinally, and the first side 1 and the second side 2 respectively include The first arc-shaped surface 3 and the second arc-shaped surface 4, a first abutment surface 5 is provided between the first arc-shaped surface 3 of the first side part 1 and the first arc-shaped surface 3 of the second side part 2, A second abutment surface 6 is provided between the second arcuate surface 4 of the first side portion 1 and the second arcuate surface 4 of the second side portion 2 , between the first abutment surface 5 and the second abutment surface 6 The distance between them defines the thickness of the fiberboard; the two ends of the first abutment surface 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com