Ultrasonic image diagnostic imaging preparation raw material fine processing device

A technology for diagnostic imaging and ultrasonic imaging, which is applied in mixers with rotating stirring devices, transportation and packaging, and dry gas layout, etc., can solve the problems of low efficiency, insufficient energy saving and environmental protection, and large volume, and achieves improved processing effect and Efficiency, novel and compact structure, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

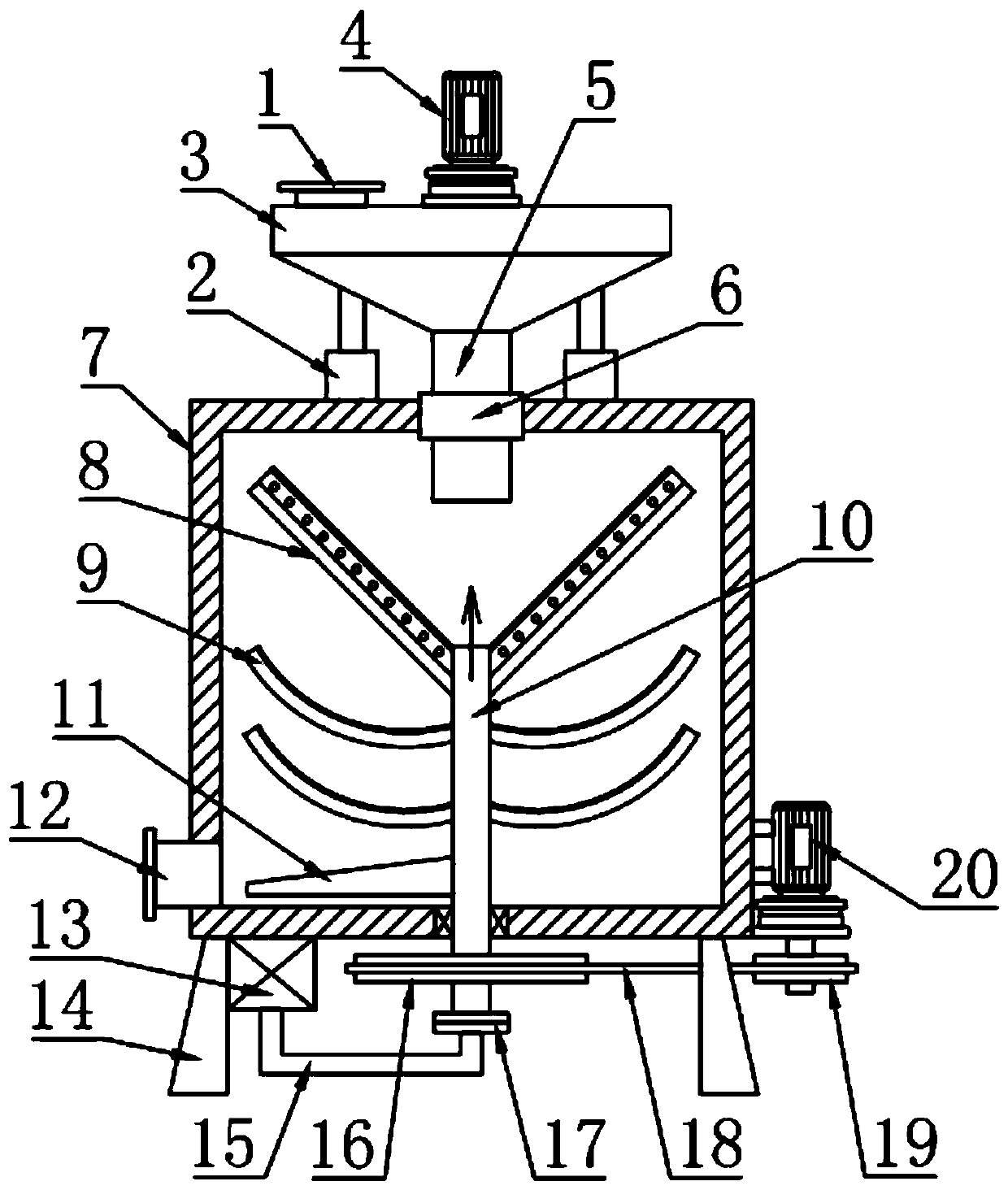

[0027] see Figure 1-3 , in an embodiment of the present invention, a fine processing device for raw materials of ultrasonic imaging diagnostic imaging preparations, including a body 7, the body 7 can be set as a cylindrical barrel structure with both ends closed, and the bottom of the body 7 is provided with supporting legs 14 , the device can be stably supported by the support legs 14, and walking wheels can be installed at the lower end of the support legs 14, which is beneficial to the movement of the device.

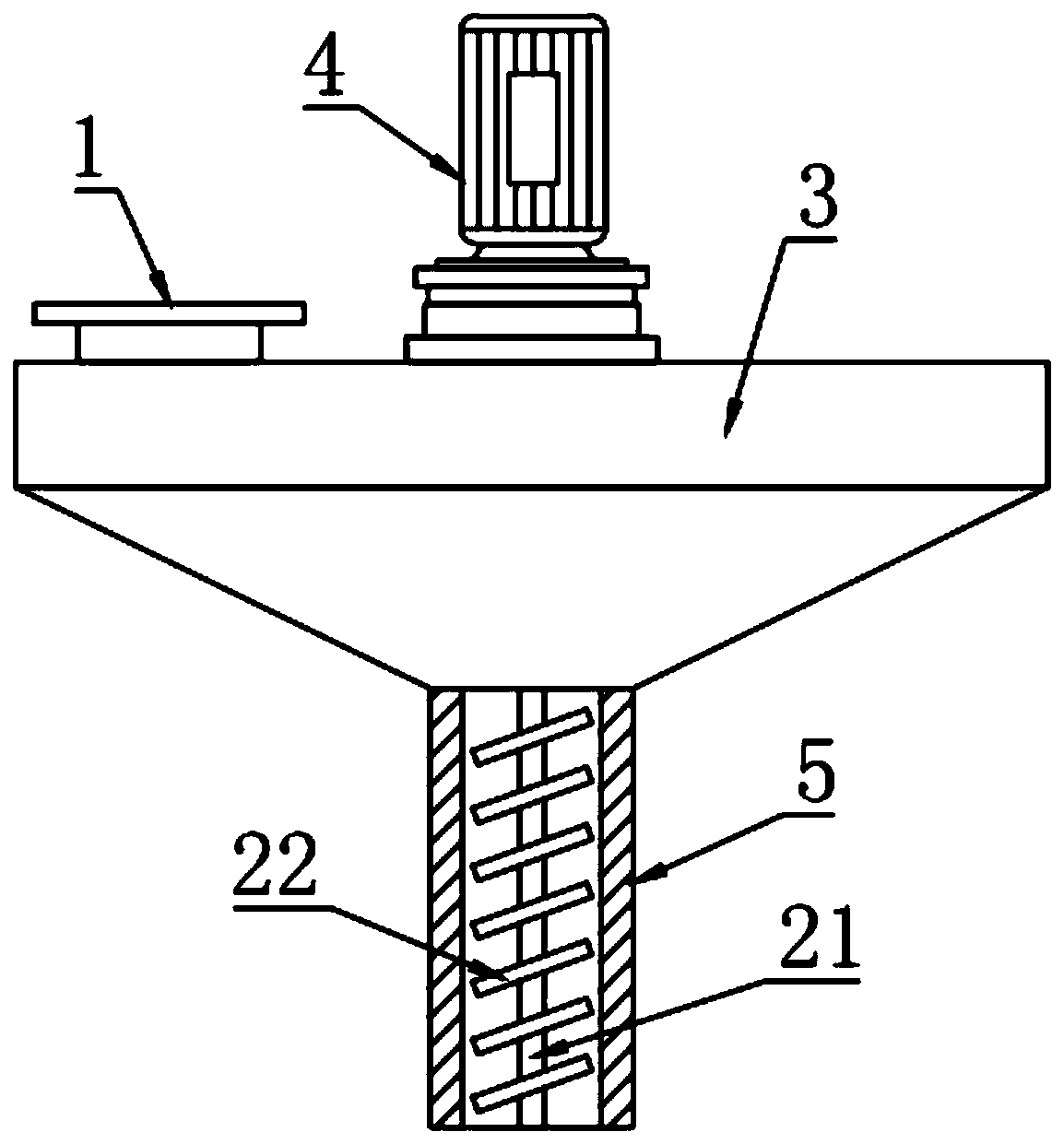

[0028] The top of the body 7 is equipped with a screw feeding mechanism, and the top of the body 7 is also provided with a telescopic device 2 for pushing the screw feeding mechanism to move up and down. Specifically, the screw feeding mechanism includes a material box 3, a feeding motor 4. Feeding cylinder 5, guide cylinder 6, feeding shaft 21 and screw blade 22, the guide cylinder 6 is installed and fixed at the top middle position of the body 7, and the guide cyl...

Embodiment 2

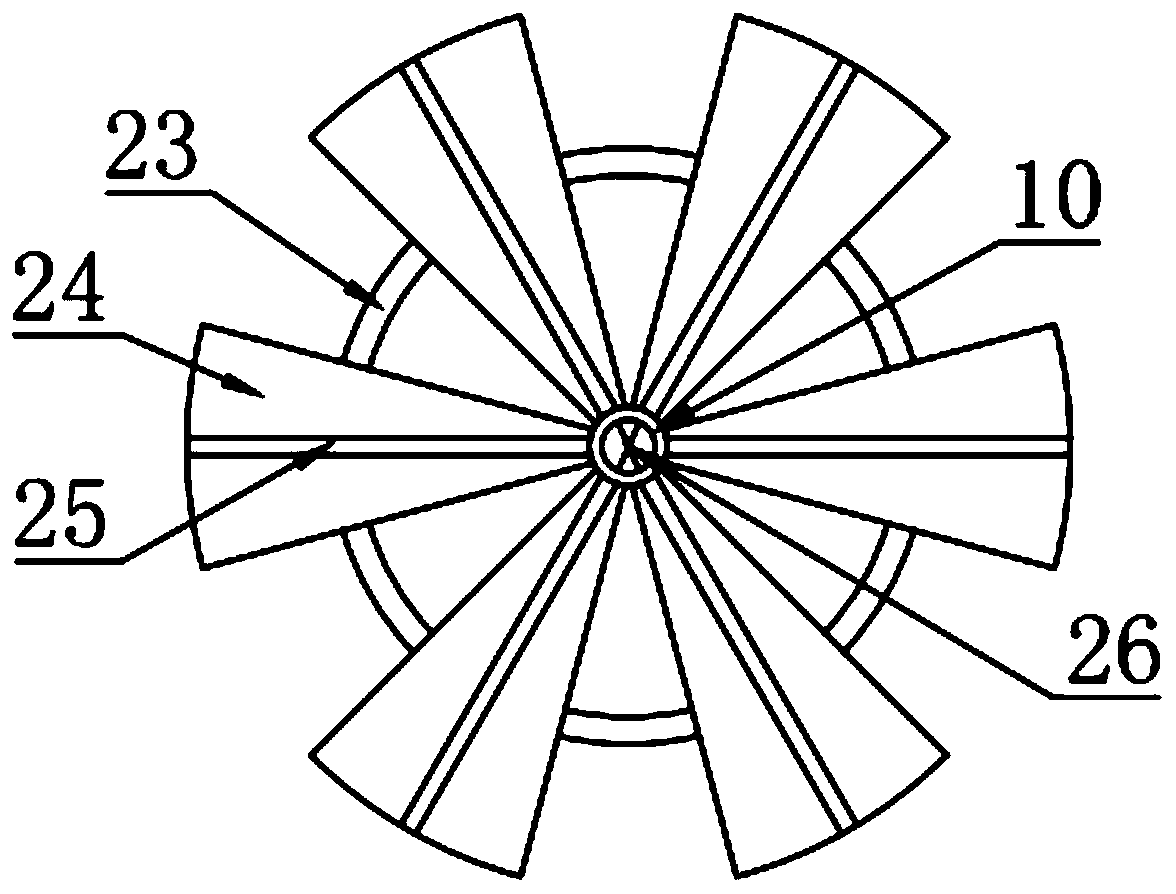

[0033] see image 3, the difference between this embodiment and embodiment 1 is:

[0034] In this embodiment, there are six crushing mechanisms 8 evenly arranged in the circumferential direction. The crushing mechanism 8 includes a material-loading centrifugal plate 24 and a crushing knife 25. The top view of the material-loading centrifugal plate 24 is a 1 / 12 fan-shaped structure, and the loading The material centrifugal plate 24 has an arc-shaped concave structure in the middle, and a crushing knife 25 is fixedly arranged in the middle of the top of the material-carrying centrifugal plate 24. Through holes, the top of the crushing knife 25 is also provided with a blade. In order to improve the stability of each crushing mechanism 8, an arc-shaped connecting rod 23 is also arranged between two adjacent crushing mechanisms 8, and the material-carrying centrifugal plate 24 can be used for The raw material is received and centrifuged, and the raw material can be crushed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com