Mas-nmr rotor system with improved space utilization

A nuclear magnetic resonance and rotor technology, which is applied in the direction of using nuclear magnetic resonance spectrum for measurement, magnetic resonance measurement, and magnetic variable measurement, can solve the problem that insulation devices are difficult to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

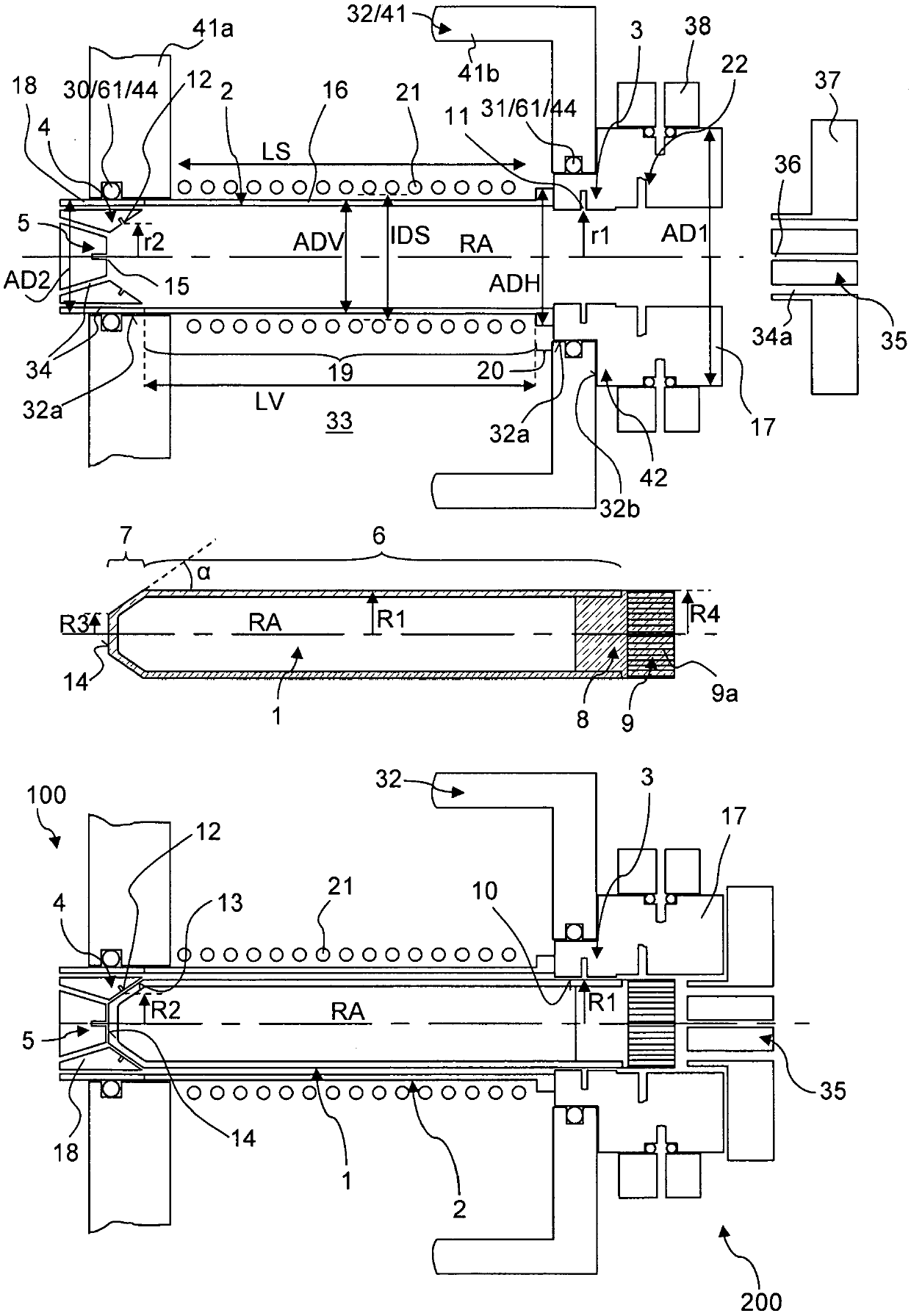

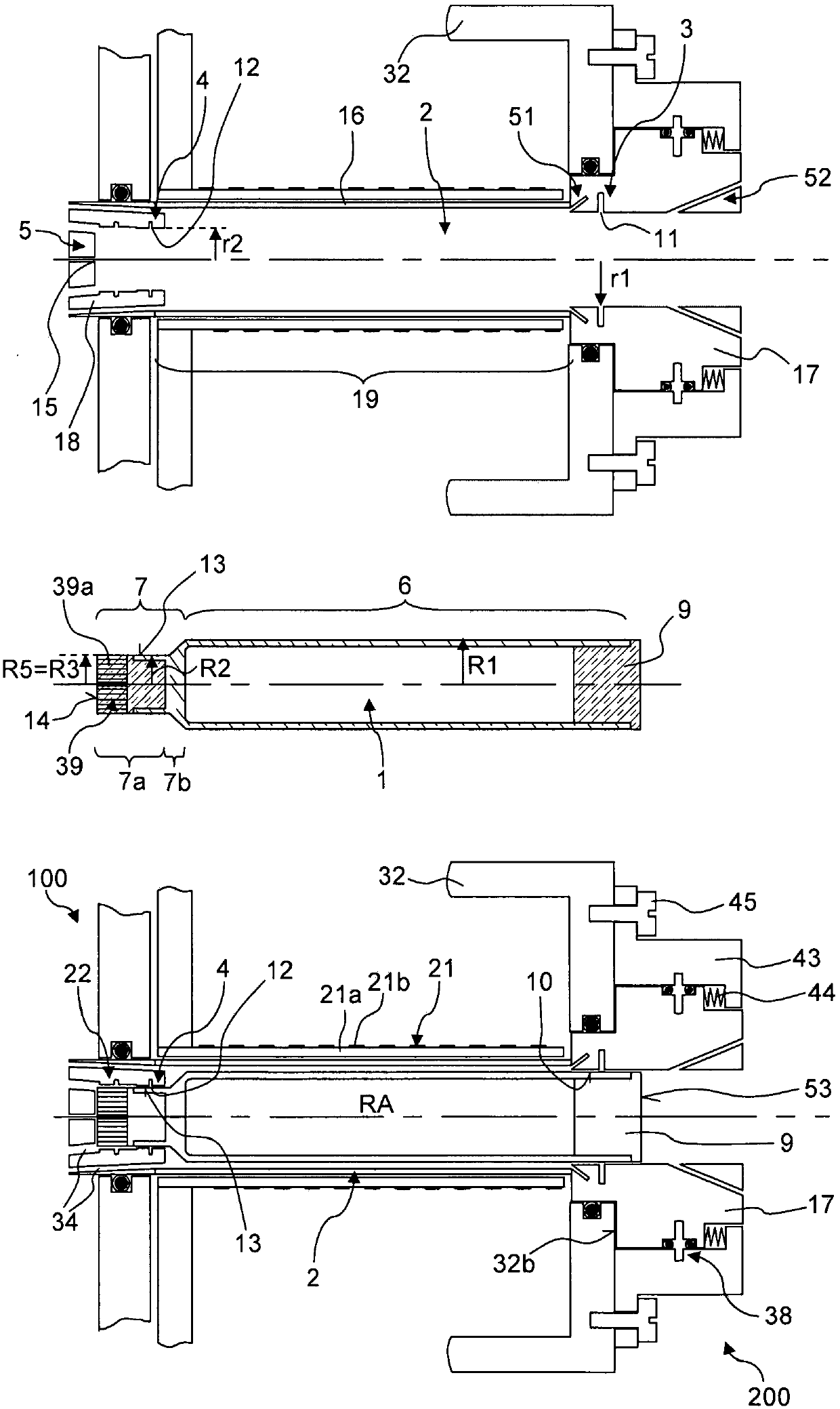

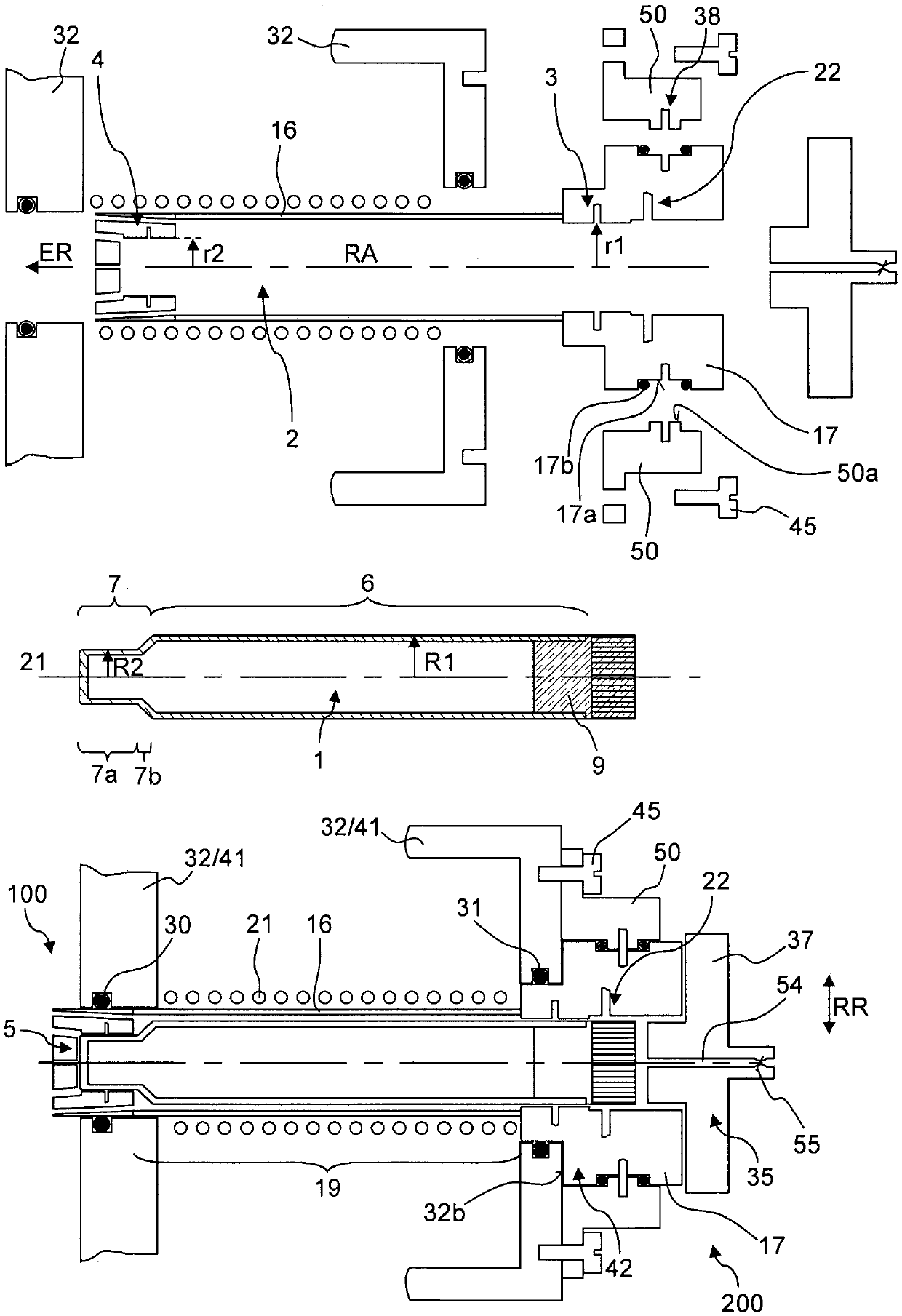

[0058] figure 1 A first embodiment of a MAS-NMR rotor system 100 for the invention is shown, comprising a rotor 1 in which a measurement substance is arranged in solid or semi-solid form (eg powder or gel) and comprising a stator 2 . exist figure 1 The stator 2 is shown above (together with the components of the stator holder 32), in figure 1 Rotor 1 is shown in the center and in figure 1 The entire MAS-NMR rotor system 100 with the rotor 1 and the stator 2 (together with the components of the stator holder 32 ) is shown below. The MAS-NMR rotor system 100 and the stator holder 32 are part of a probe assembly 200 according to the invention.

[0059] The stator 2 comprises a first aerodynamic radial bearing 3 , a second aerodynamic radial bearing 4 and a third aerodynamic axial bearing 5 . The rotor 1 is mounted rotatably about an axis of rotation RA within the stator 2 .

[0060] The rotor 1 comprises a cylindrical section 6 and an end section 7, which forms the main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com