A pressure sensor with high sensitivity and wide range

A pressure sensor, high-sensitivity technology, applied in the measurement of the property force of piezoelectric devices, and the measurement of property force of piezoelectric resistance materials, etc., can solve problems such as low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

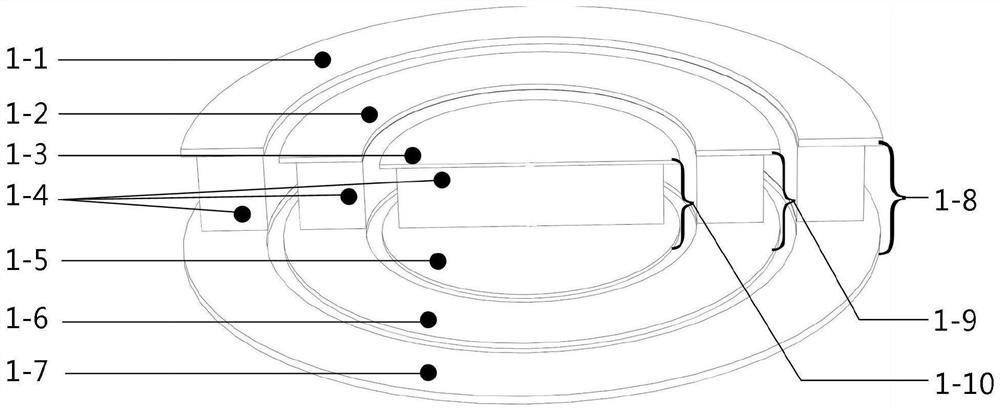

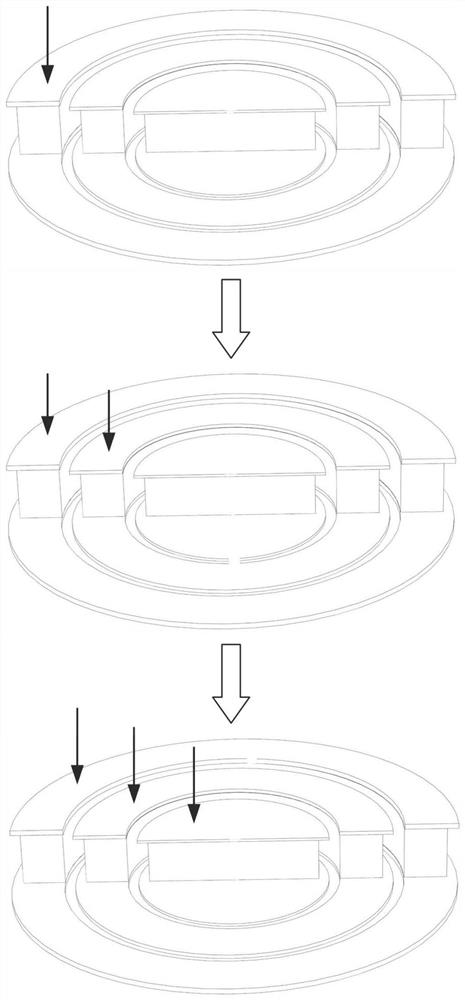

[0025] As shown in Figure 1, a high-sensitivity and wide-range pressure sensor of this embodiment includes a housing and a plurality of sensing elements located in the housing; each sensing element includes a pressure-capacitive / piezoresistive sensitive material 1- 4 and an upper electrode plate and a lower electrode plate respectively arranged on the upper and lower sides of the sensitive material 1-4; multiple sensing elements include a central sensing element 1-10 and a second stage concentrically sheathed on the central sensing element 1-10 Sensing elements 1-9 and outermost-level sensing elements 1-8, and the thickness of each level of sensing elements in the sensor gradually decreases from the outer level to the center, that is, the outermost-level sensing elements 1-8, the second The thicknesses of the sensitive materials 1-4 of the level sensor elements 1-9 and the center sensor elements 1-10 decrease successively (the thickness of the electrode plates of the sensor ele...

Embodiment 2

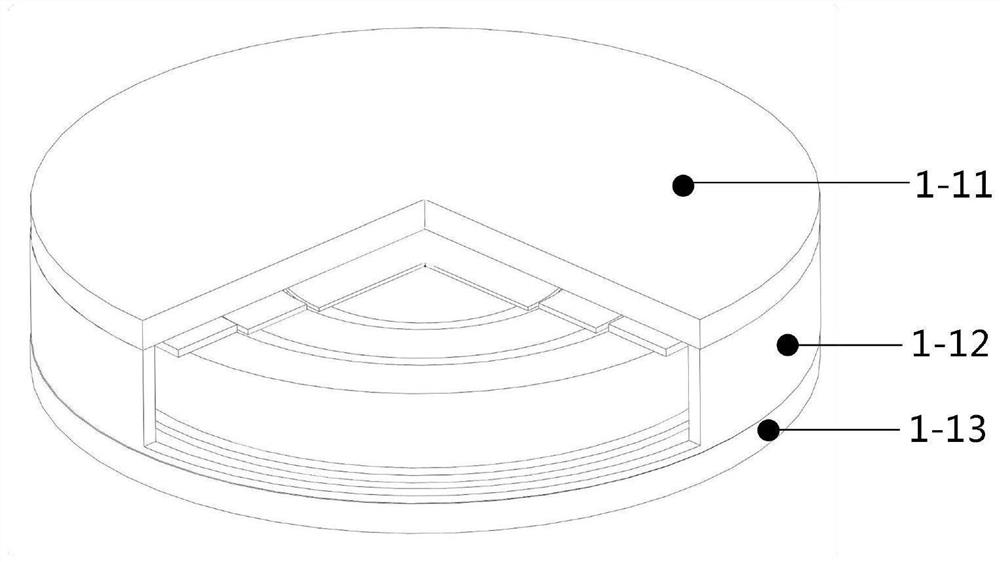

[0028] like image 3 As shown, a high-sensitivity and wide-range pressure sensor of this embodiment includes a housing and a multi-stage sensing element located in the housing, which is the same as in Embodiment 1. The housing includes a top surface (not shown in the figure), a bottom surface 2 -2 and the side 2-1 connected between the top surface and the bottom surface 2-2; each level of sensing element includes a pressure capacitive / piezoresistive sensitive material 2-7 and a sensor located on the upper and lower sides of the sensitive material 2-7 An upper electrode plate and a lower electrode plate; the multi-stage sensing elements include a central sensing element 2-4 and multiple groups of outer-level sensing elements ( image 3 Only one group is shown in the figure); the outer-level sensing element group includes six outer-level sensing elements 2-3 with the same thickness that are annularly distributed around the central sensing element 2-4, wherein the central sensing...

Embodiment 3

[0030] In this embodiment, the circular central sensor, second-level sensor element, and outermost sensor element in Embodiment 1 are replaced with concentrically arranged triangles, squares, or regular hexagons, etc., thereby forming a concentric triangular distribution. , concentric square distribution, or concentric hexagonal distribution, etc.;

[0031] Alternatively, the central sensing element and the outer sensing element of the cylindrical structure in the concentric annular independent distributed structure in the second embodiment are replaced with triangular prisms, polygonal prisms or other columnar structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com