Sound absorption wall brick

A technology for wall bricks and brick bodies, which is applied to building materials and other directions, can solve the problems of complex construction, high cost and long cycle, and achieve the effects of good heat insulation and noise reduction, high construction efficiency and good positioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

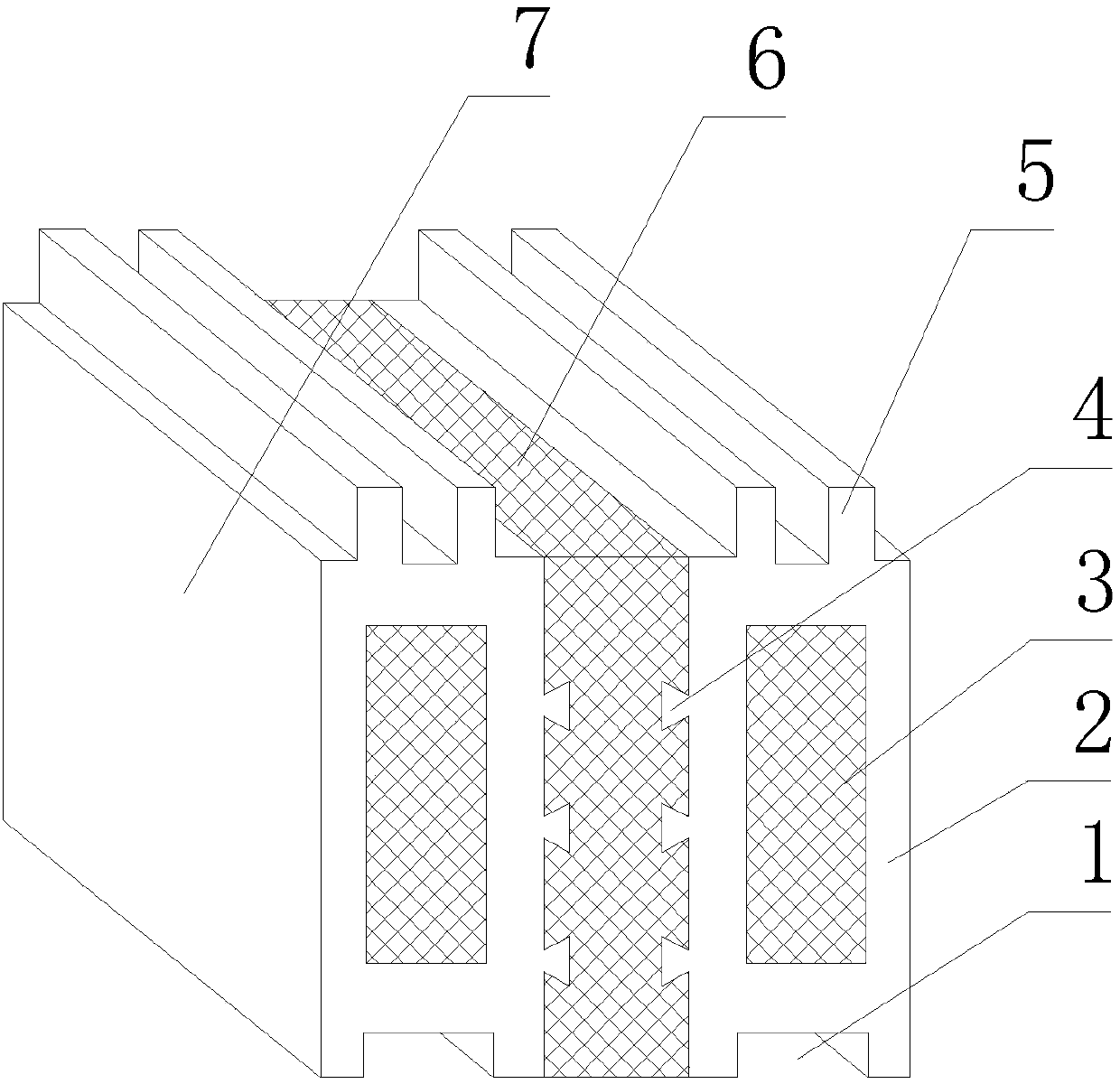

[0011] see figure 1 , figure 1 It is a structural schematic diagram of the present invention.

[0012] The sound-absorbing wall tile includes a brick body A2 and a brick body B7. The structure of the brick body A2 and the brick body B7 is symmetrical, and a sound insulation layer 6 is arranged between the brick body A2 and the brick body B7. The brick body A groove 1 is arranged on the body A2 and the brick body B7, and a convex strip 5 adapted to the groove 1 is arranged on the side opposite to the groove 1 on the brick body A2 and the brick body B7. The brick body A2, the brick body The middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com