Polyurethane adhesive with degradation features and preparation method thereof

A technology of polyurethane adhesives and polyurethane prepolymers, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as endangering consumers' health, solvent residue, slow degradation, etc., and improve production and construction Effect of environment, good adhesive performance, good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

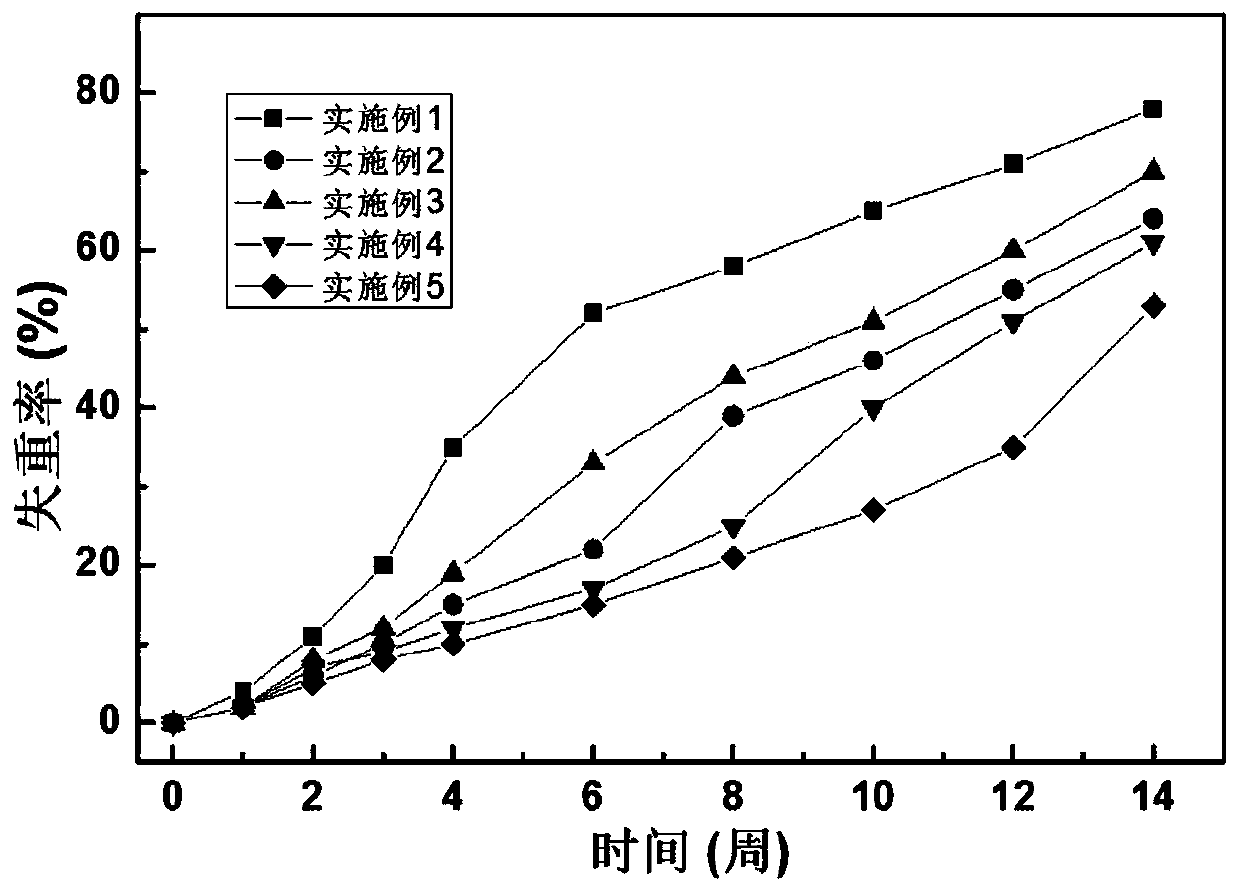

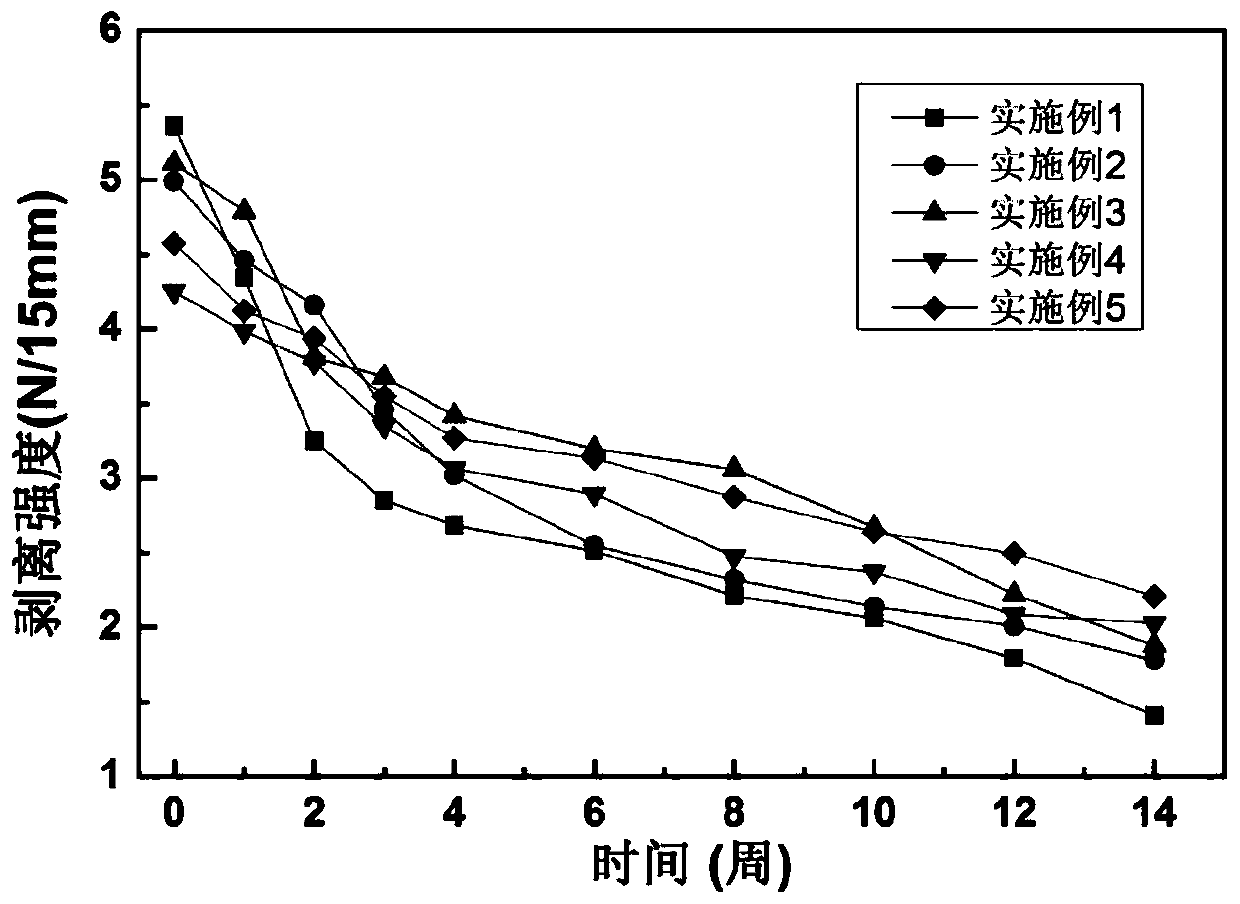

Examples

Embodiment 1

[0041] The polyurethane adhesive with degradation characteristics provided in this example, the polyurethane adhesive includes A component and B component, A component is a polyurethane prepolymer terminated by isocyanate group (NCO), and B component is a hydroxyl (OH) terminated poly Hydroxyl compound, the molar ratio of isocyanate group (NCO) in component A to hydroxyl group (OH) in component B is n(NCO) / n(OH)=1.2:1, where:

[0042] Component A is made of the following raw materials in parts by mass:

[0043] Oligomer resin 55

[0044] Polyisocyanate 85

[0045] Component B is made of the following raw materials in parts by mass:

[0046] Polyol 70

[0047] Polyisocyanate 24

[0048] Defoamer 0.5;

[0049] In component A:

[0050] The oligomer resin is prepared by reacting polybasic acid with degradable polypolyol and polyol through polyester.

[0051] The polybasic acid is malic acid.

[0052] The degradable polypolyol is polylactide.

[0053] Polyols are ethylene ...

Embodiment 2

[0070] The polyurethane adhesive with degradation characteristics provided in this example, the polyurethane adhesive includes A component and B component, A component is a polyurethane prepolymer terminated by isocyanate group (NCO), and B component is a hydroxyl (OH) terminated poly Hydroxyl compound, the molar ratio of isocyanate group (NCO) in component A to hydroxyl group (OH) in component B is n(NCO) / n(OH)=1.5:1, where:

[0071] Component A is made of the following raw materials in parts by mass:

[0072] Oligomer resin 46

[0073] Polyisocyanate 98

[0074] Component B is made of the following raw materials in parts by mass:

[0075] Polyol 85

[0076] Polyisocyanate 16

[0077] Defoamer 0.6;

[0078] In component A:

[0079] The oligomer resin is prepared by reacting polybasic acid with degradable polypolyol and polyol through polyester.

[0080] The polybasic acid is citric acid.

[0081] The degradable polypolyol is polyglycolic acid.

[0082] The polyols ar...

Embodiment 3

[0099] The polyurethane adhesive with degradation characteristics provided in this example, the polyurethane adhesive includes A component and B component, A component is a polyurethane prepolymer terminated by isocyanate group (NCO), and B component is a hydroxyl (OH) terminated poly Hydroxyl compound, the molar ratio of isocyanate group (NCO) in component A to hydroxyl group (OH) in component B is n(NCO) / n(OH)=2.0:1, where:

[0100] Component A is made of the following raw materials in parts by mass:

[0101] Oligomer resin 60

[0102] Polyisocyanate 98

[0103] Component B is made of the following raw materials in parts by mass:

[0104] Polyol 81

[0105] Polyisocyanate 18

[0106] Defoamer 0.7;

[0107] The oligomer resin is prepared by reacting polybasic acid with degradable polyol and polyol through polyester.

[0108] In component A:

[0109] The polybasic acid is aspartic acid.

[0110] The degradable polypolyol is poly-3-hydroxybutyrate.

[0111] The polyols...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com