Double-disc paper cup machine

A paper cup machine and cup body technology, which is used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of large machine dimensions, unconcentrated transmission of double-disc paper cup machines, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

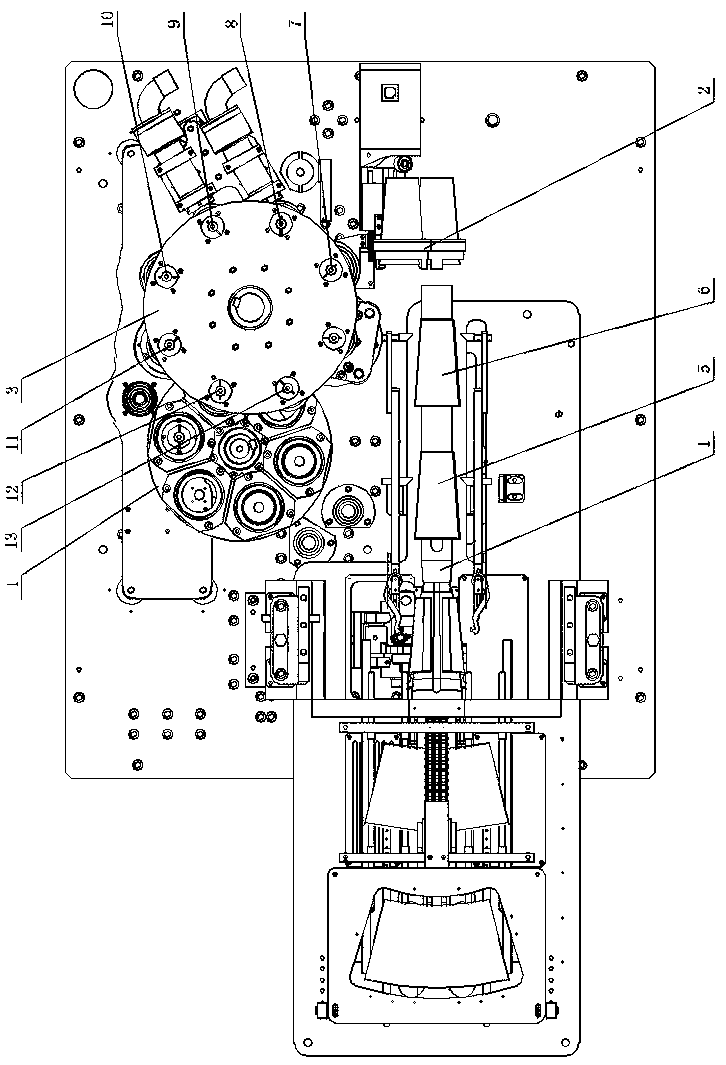

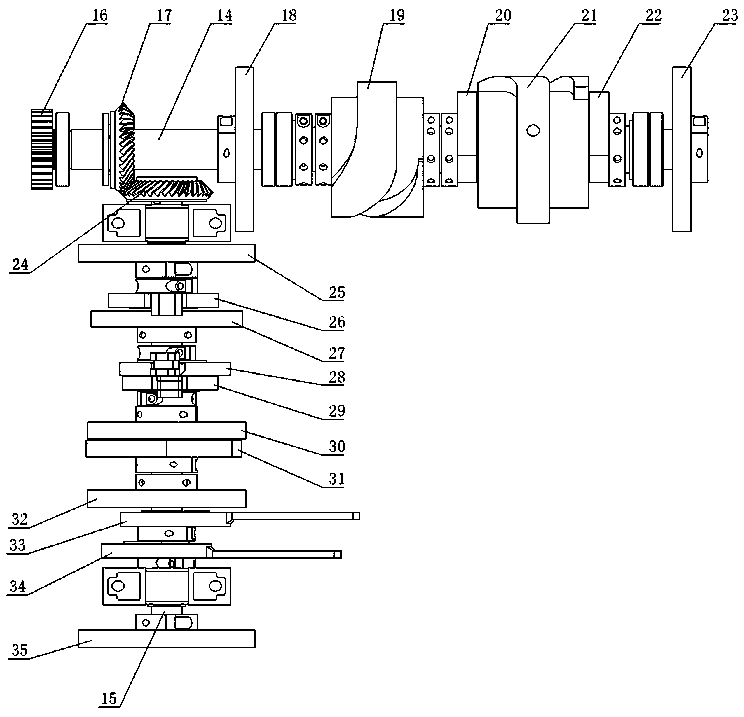

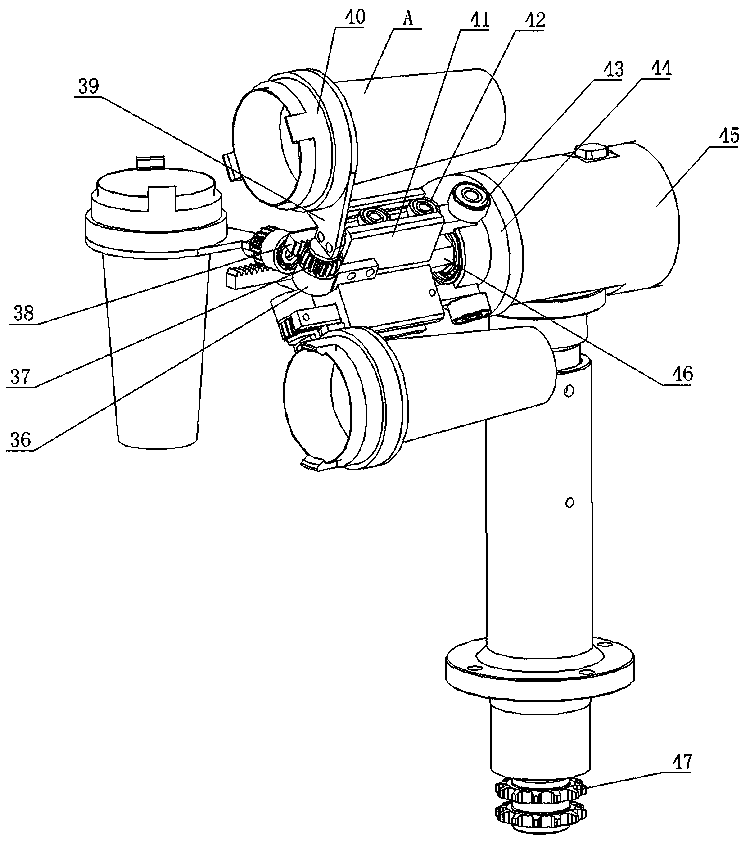

[0019] As shown in the figure, the double-disk paper cup machine of the present invention includes a cup body forming mechanism 1, a vertically installed first turntable 3 and a vertically installed second turntable 4, and the cup body forming mechanism 1 is provided with two The hooking cup cylinder stations 5 and 6, the first turntable 3 only has eight stations along the counterclockwise circumference, which are respectively the upper bottom station, the top cup cylinder station 7, the first preheating station 8, the second Preheating station 9, bottom folding station 10, knurling station 11, lower cup station 12 and free station 13, the second turntable 4 is provided with cup receiving station, free station, The pre-rolling station, the second-rolling station, the testing station and the cup-out station, and the cup-down station 12 are aligned up and down with the cup-connecting station.

[0020] A cup transfer mechanism 2 is provided between the cup body forming mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com