A kind of preparation method of bearing cage material and the preparation method of bearing cage

A technology for bearing cages and raw materials, which is applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve the limitations of large-scale application of polyimide materials, high cost of polyimide cage materials, easy loss of molds, etc. Problems, to achieve good economic benefits, low cost, high molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

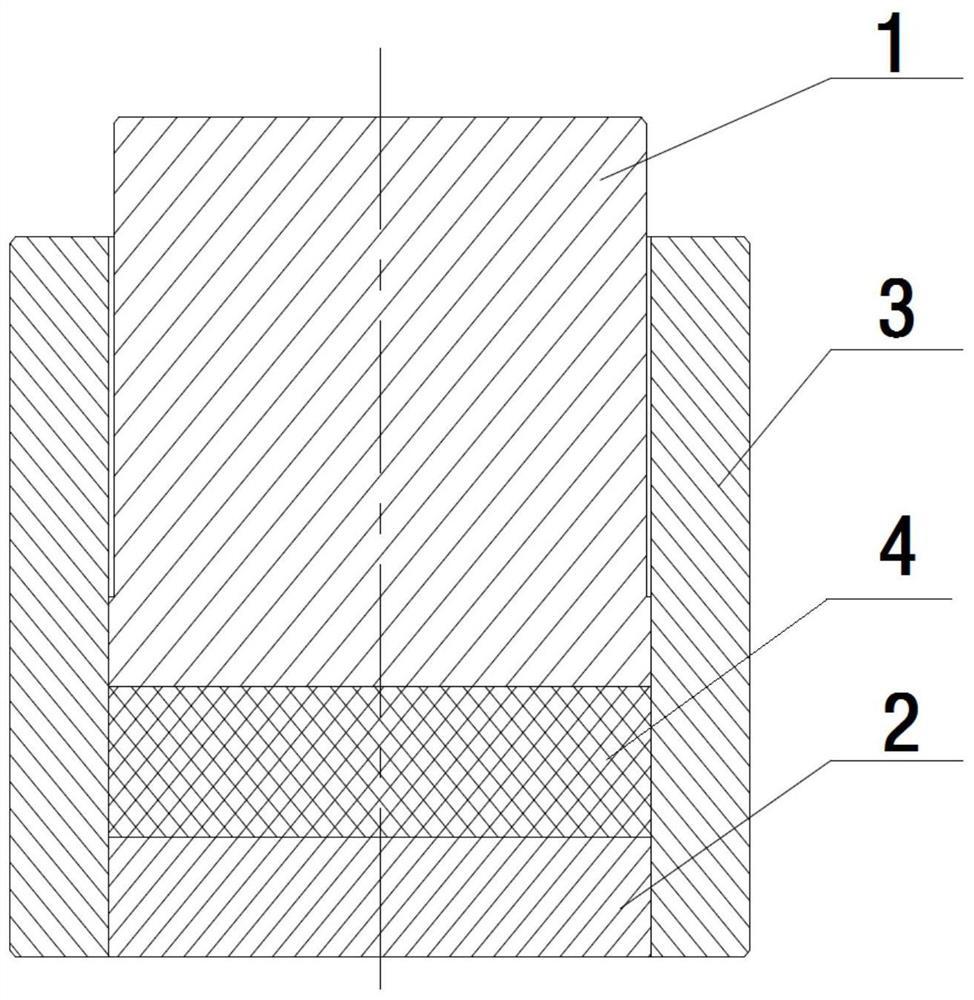

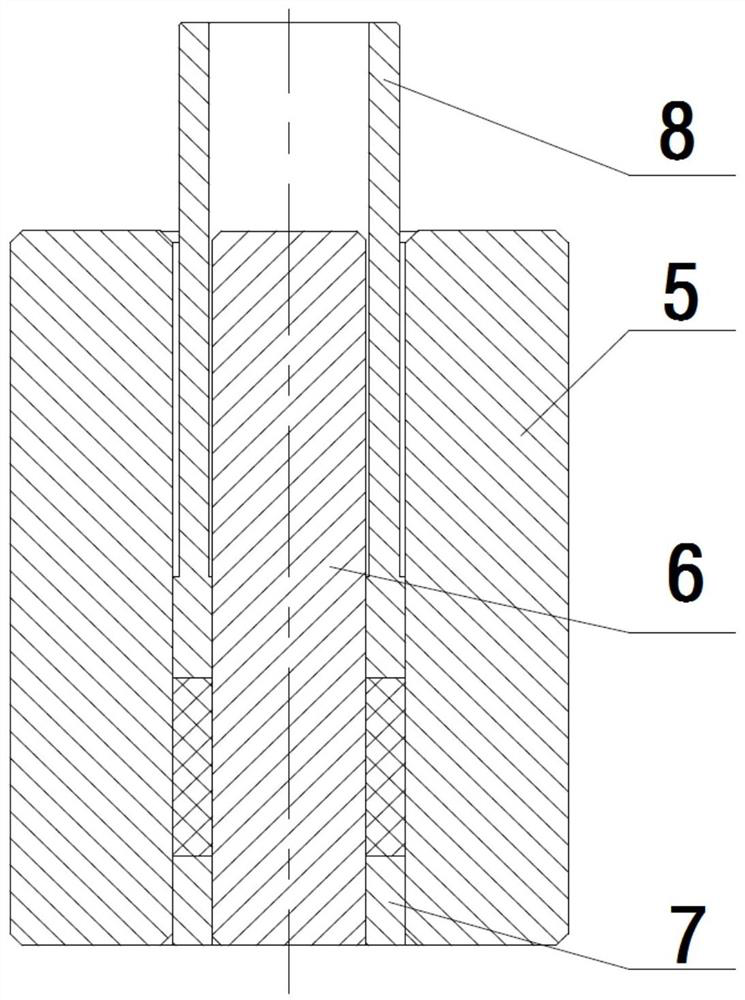

[0028] The preparation method of the bearing cage material provided by the invention comprises the following steps:

[0029] 1) Provide raw materials whose main component is polyimide;

[0030] 2) The raw material is hot-pressed to form a plate-shaped polyimide material, and then the plate-shaped polyimide material is made into a rod shape to obtain the product.

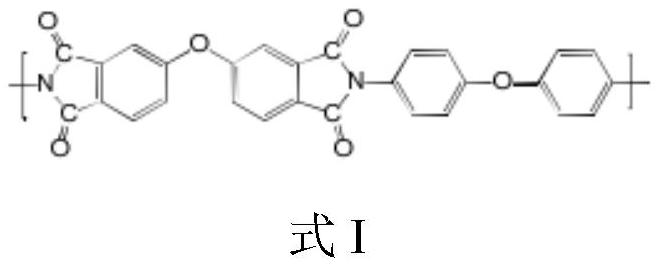

[0031] Preferably, the polyimide used is thermoplastic polyimide. The thermoplastic polyimide is selected from one of monoether anhydride polyimide and bisether anhydride polyimide. The raw material may only contain polyimide, or may contain other additives. Generally, the mass proportion of polyimide is not less than 60%. When the mixture contains other additives besides polyimide, the prepared plate polyimide material is a plate polyimide composite material.

[0032] In order to further enhance the tensile strength and wear resistance of the material, preferably, the particle size of the raw material is not less...

Embodiment 1

[0068] The preparation method of the bearing cage material of the present embodiment comprises the following steps:

[0069] 1) Dry the thermoplastic polyimide, reinforcing agent and lubricant separately, pass through a 200-mesh sieve after cooling to room temperature, and then independently seal and store them for later use; the temperature for drying the thermoplastic polyimide is 220°C, and the time is 3h; the reinforcing agent and lubricant are dried at 150°C for 3 hours; the thermoplastic polyimide used is Ratem-YS20, the reinforcing agent is glass fiber, and the lubricant is molybdenum disulfide.

[0070] 2) According to the mass ratio of thermoplastic polyimide, reinforcing agent and lubricant at a ratio of 70:20:10, take the dried thermoplastic polyimide, reinforcing agent and lubricant respectively and put them into a high-speed tissue grinder Stir 3 times to obtain polyimide compound (i.e. raw material); The time of each stirring is 10s, and the rotating speed of mec...

Embodiment 2

[0075] The preparation method of the bearing cage material of the present embodiment comprises the following steps:

[0076] 1) Dry the thermoplastic polyimide, reinforcing agent and lubricant separately, pass through a 200-mesh sieve after cooling to room temperature, and then independently seal and store them for later use; the temperature for drying the thermoplastic polyimide is 220°C, and the time is The drying time of reinforcing agent and lubricant is 150℃ and the drying time is 3 hours; the thermoplastic polyimide used is YHPI-P-100, the reinforcing agent is glass fiber, and the lubricant is molybdenum disulfide.

[0077] 2) According to the mass ratio of thermoplastic polyimide, reinforcing agent and lubricant at a ratio of 85:18:5, take the dried thermoplastic polyimide, reinforcing agent and lubricant respectively and put them into a high-speed tissue masher Stir 3 times to obtain polyimide compound (i.e. raw material); The time of each stirring is 10s, and the rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com