A fixture for assembly of multi-type planetary roller screw pairs

A technology of planetary rollers and assembly fixtures, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve the problems of transmission accuracy and equipment service life reduction, complex meshing relationship, and difficult assembly, etc., to achieve simple structure and multiple applicable models , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

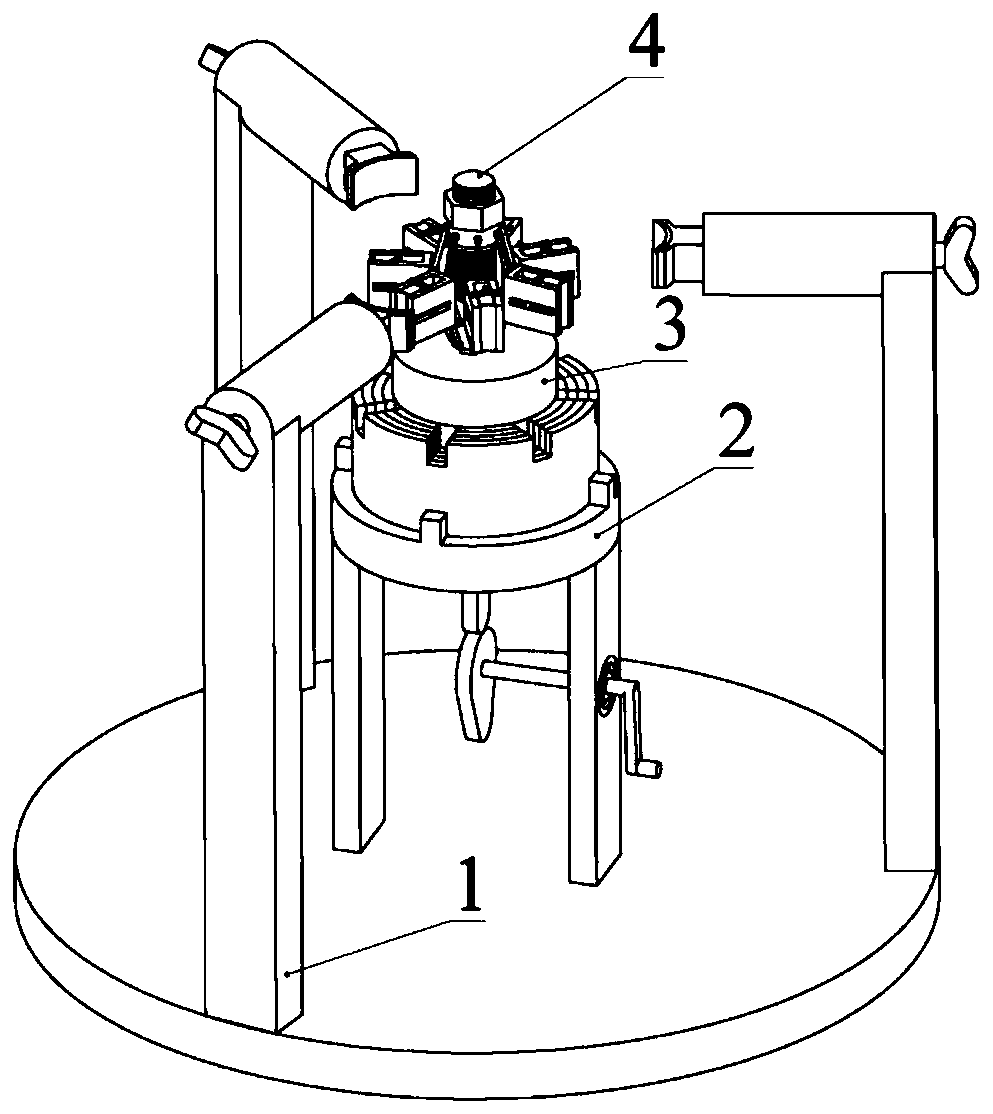

[0024] This embodiment is a fixture for assembling multiple types of planetary roller screw pairs.

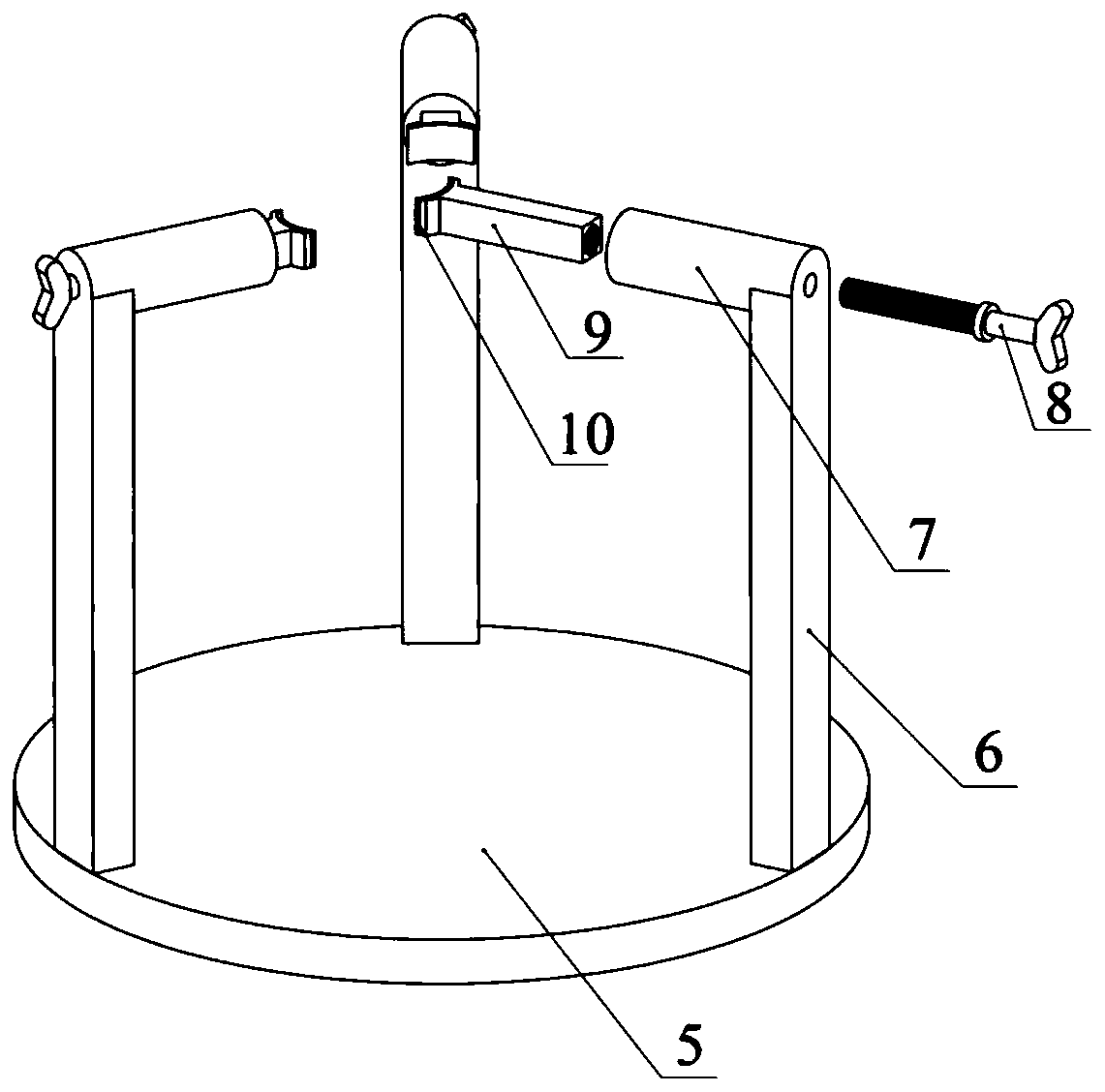

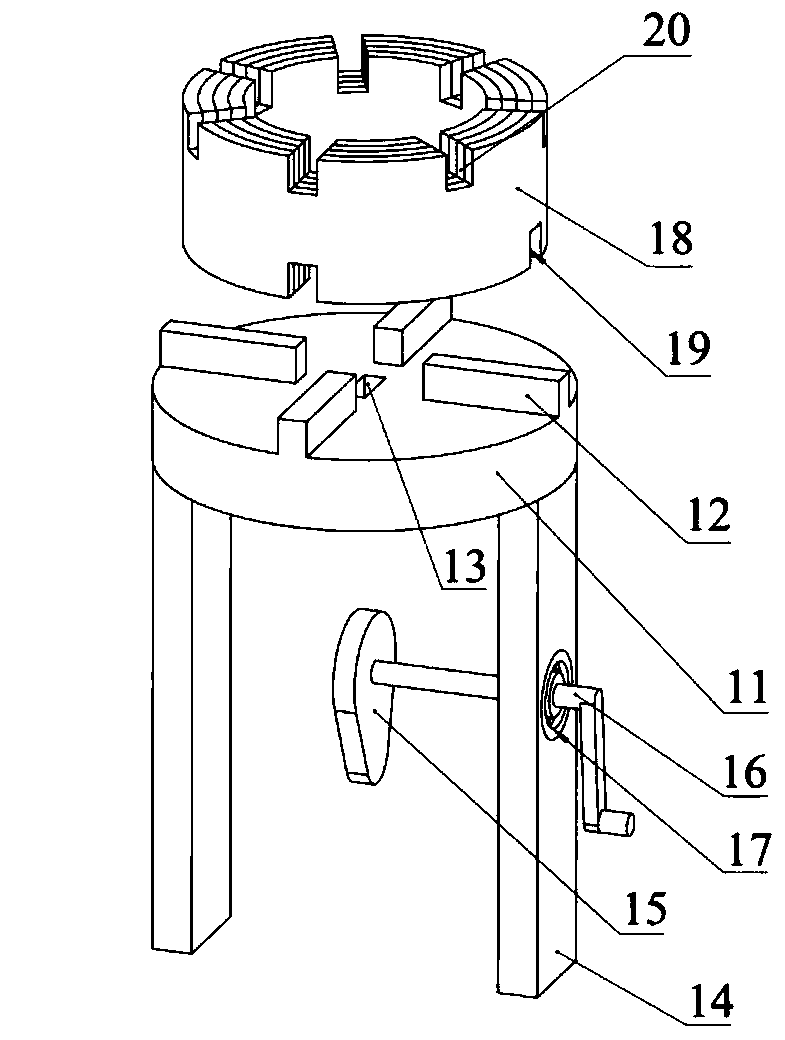

[0025] refer to Figure 1 to Figure 7 , this embodiment is used for multiple types of planetary roller screw assembly fixtures, consisting of a three-jaw fixing assembly 1 for fixing the horizontal position of the nut, a nut support assembly 2 for positioning the roller and supporting the nut, and a support assembly for supporting the umbrella The support frame 3 of the roller fixing assembly, the umbrella-shaped roller fixing assembly 4 for fixing the position of the rollers, and the base 5 are composed; the base 5 is a disc-shaped structure, and the base 5 provides support for the above-mentioned components; wherein, the nut support assembly 2 is located on In the middle part of the three-claw fixing assembly 1, the support frame 3 is located above the nut support assembly 2 and connected with the nut support assembly 2. The assembly 2, the support frame 3 and the umbrella-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com