Construction steel pipe self-adaption length control machining equipment

A technology of adaptive regulation and processing equipment, applied in the field of mechanical processing, can solve the problems of increasing the labor intensity of operators and reducing the efficiency of cutting and processing operations, and achieve the effect of ingenious structure, convenient length and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

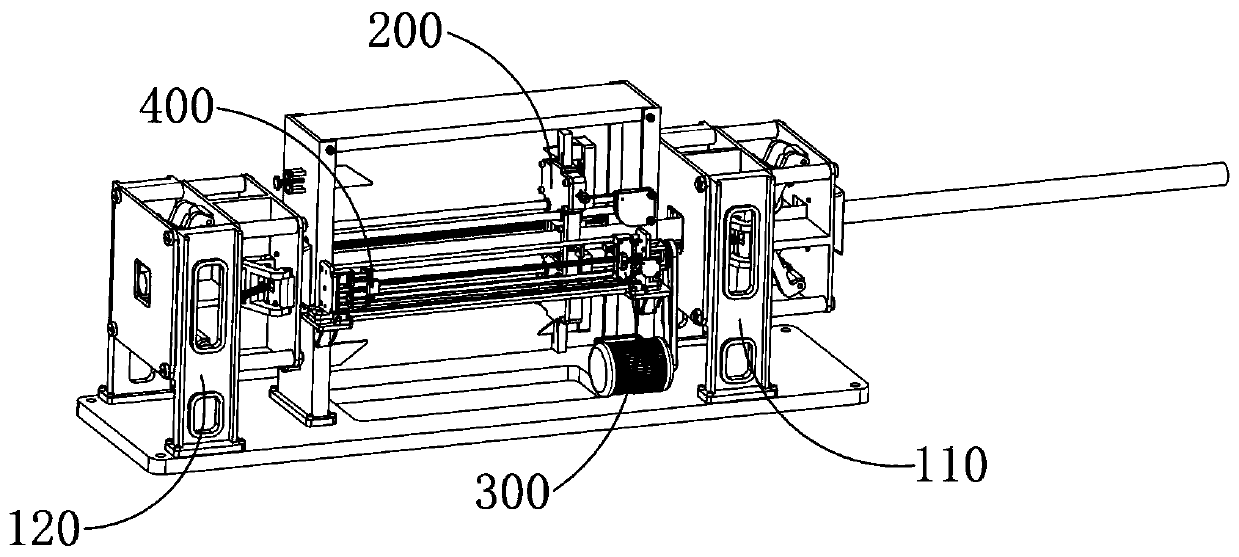

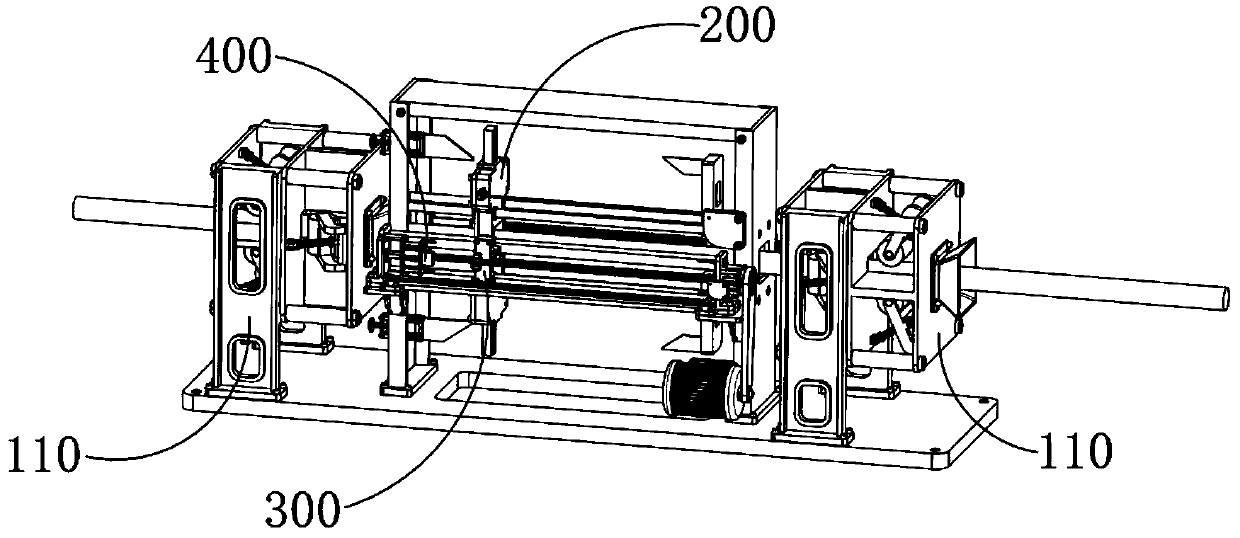

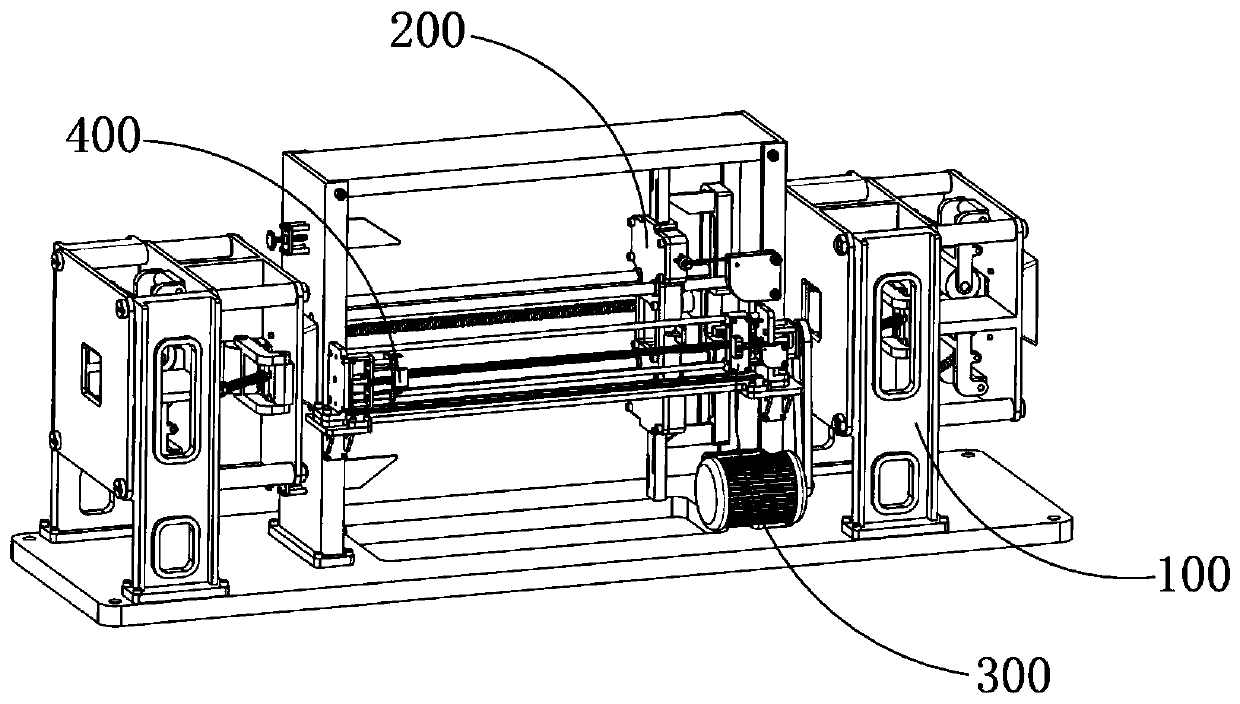

[0056] The processing equipment for self-adaptive regulation of the length of construction steel pipes includes a guiding device 100, an intermittent propulsion device 200, a power driving device 300 and a retraction reset device 400. The guiding device 100 includes a device for inputting and clamping bars. The input guide mechanism 110, the output guide mechanism 120 for outputting bar stock and clamping it, the intermittent propulsion device 200 is arranged between the input guide mechanism 110 and the output guide mechanism 120 and its input end is connected with the input guide mechanism 110 The output end is connected, the output end is connected with the input end of the output guiding mechanism 120, the power drive device 300 is used to provide power for the clamping and propulsion of the intermittent propulsion device 200, and the retraction reset device 400 is used to cut off the power of the power drive device 300. The power is output and the power driving device 300 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com