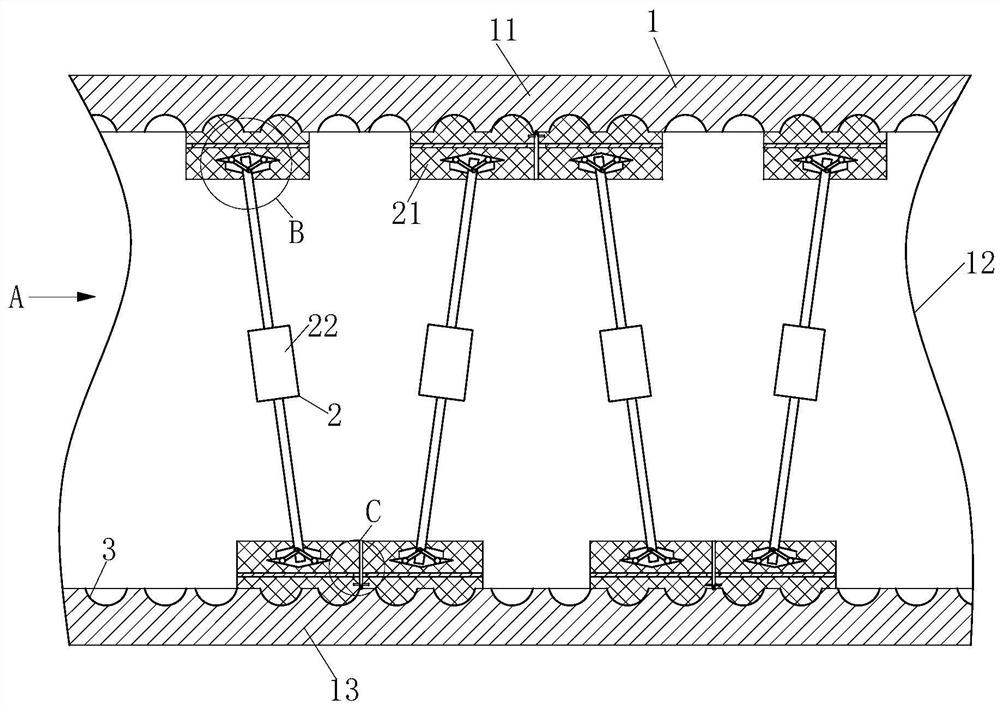

An assembled I-beam

An I-beam and assembled technology, applied in the direction of feeding devices, manufacturing tools, metal processing, etc., can solve difficult and dangerous problems, and achieve the effects of improving service life, increasing contact surface, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

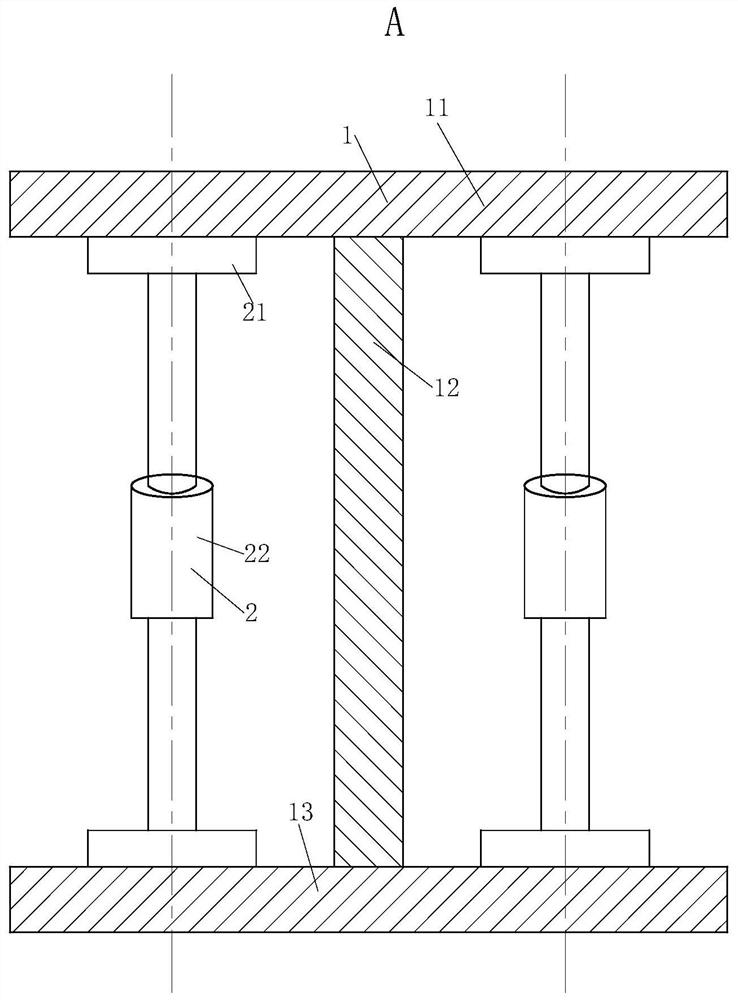

Examples

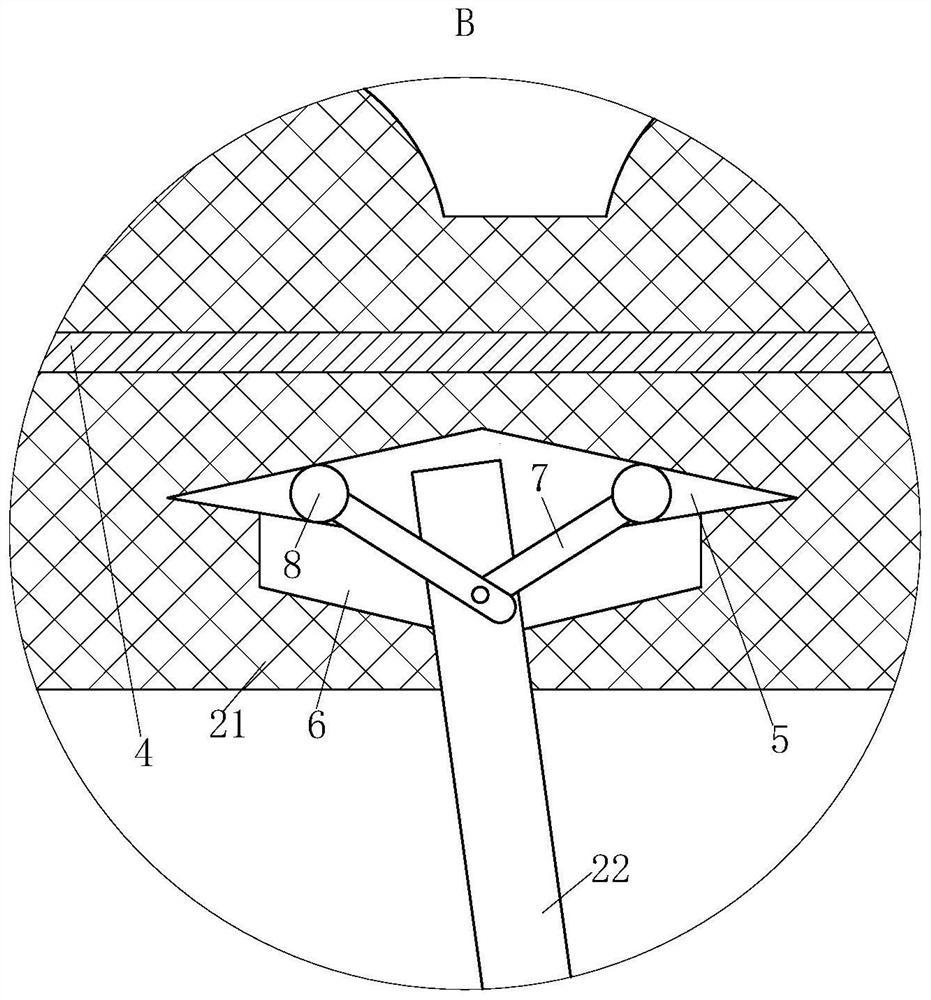

Embodiment approach

[0022] As an embodiment of the present invention, the support plate 21 is made of nylon, and a No. 1 groove is provided in the middle of the support plate 21, and the metal plate 4 is fixedly installed in the No. 1 groove. The metal plate 4 in the No. 1 groove can be replaced with the material of the plate according to the supporting strength of the I-beam 1, and the replacement is convenient. The correction module 2 can be used for the correction of the I-beam 1 of different materials; the support plate 21 made of nylon and the I-beam The contact effect of 1 is good, and the support plate 21 made of nylon has toughness and is not easy to break; but the support plate 21 made of nylon has low support strength, low hardness, and is easy to bend; so the piston rod of the biaxial hydraulic cylinder 22 and the support plate 21 are not Direct contact, the piston rod of the biaxial hydraulic cylinder 22 is in contact with the metal plate 4, the piston end of the biaxial hydraulic cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com