Adsorption resin for adsorption and separation of polycyclic aromatic hydrocarbons in coal tar, preparation method and application thereof

An adsorption resin and adsorption separation technology, which is applied in the field of adsorption resin for adsorption and separation of polycyclic aromatic hydrocarbons in coal tar and its preparation, can solve the problems of inability to separate polycyclic aromatic hydrocarbons and alkanes, high energy consumption for separation, and high hydrogen consumption , to achieve the effect of low cost, simple preparation method and high degree of branching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

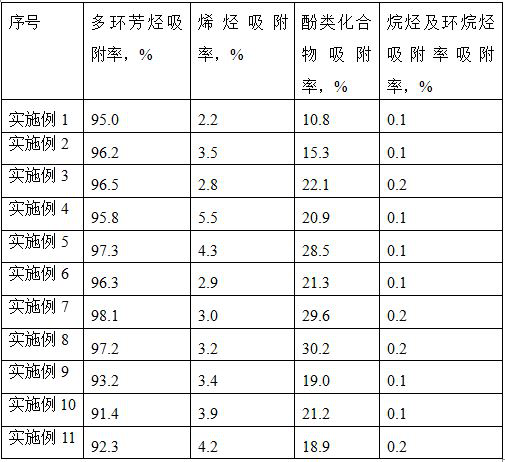

Examples

Embodiment 1

[0027] An adsorption separation coal tar Adsorption of polycyclic aromatic hydrocarbons, a feed component A and component B, 0.5% by weight of component B times the weight of component A;

[0028] The components A, according to 100% by weight basis from the following raw material composition: hydrophobic monomer perfluoro 3% stearyl acrylate, styrene 45%, N- methylpyrrolidone 25%, hydroxyethyl methacrylate 27 %;

[0029] The component B is azobisisobutyronitrile initiator.

[0030] The method of preparation of the adsorbent resin, comprising the steps of:

[0031] (1) The component A and component B are mixed, put into an autoclave, the autoclave 30min propane into air removal, and then sealed autoclave;

[0032] (2) The reactor pressure is first raised to 3.2MPa, then warmed to 98 ℃, and the reaction pressure was raised to the second 4.2MPa, and then the reaction 3h, to give a white powder;

[0033] (3) Step (2) obtained after the solid was triturated, extrusion pelletization of ...

Embodiment 2

[0036] An adsorption separation coal tar Adsorption of polycyclic aromatic hydrocarbons, a feed component A and component B, 0.5% by weight of component B times the weight of component A;

[0037] The components A, according to 100% by weight basis from the following raw material composition: hydrophobic monomer perfluoro lauryl acrylate 5% acrylic acid, styrene 50%, N- methylpyrrolidone 30%, hydroxyethyl methacrylate 15%;

[0038] The component B is azobisisobutyronitrile initiator.

[0039] The method of preparation of the adsorbent resin, comprising the steps of:

[0040] (1) The component A and component B are mixed, put into an autoclave, the autoclave 30min propane into air removal, and then sealed autoclave;

[0041] (2) The reactor pressure is first raised to 3.2MPa, and then heated to 108 ℃, and the reaction pressure was raised to the second 4.5MPa, and then the reaction 3h, to give a white powder;

[0042] (3) Step (2) obtained after the solid was triturated, extrusion p...

Embodiment 3

[0045] An adsorption separation coal tar Adsorption of polycyclic aromatic hydrocarbons, a feed component A and component B, 0.6 times the weight of component B by weight of component A;

[0046] The components A, according to 100% by weight basis from the following raw material composition: hydrophobic monomer perfluoro acrylate, stearyl acrylate 8%, styrene 42%, N- methylpyrrolidone 25%, hydroxyethyl methacrylate 25%;

[0047] The component B is azobisisobutyronitrile initiator.

[0048] The method of preparation of the adsorbent resin, comprising the steps of:

[0049] (1) The component A and component B are mixed, put into an autoclave, the autoclave 30min propane into air removal, and then sealed autoclave;

[0050] (2) The reactor pressure is first raised to 3.5MPa, and then heated to 115 ℃, and the reaction pressure was raised to the second 5.0MPa, and then the reaction 3h, to give a white powder;

[0051] (3) Step (2) obtained after the solid was triturated, extrusion pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com