Ridging carrot planting harvester and using method thereof

A carrot and harvester technology, which is applied to excavator harvesters, harvesters, applications, etc., can solve the problems of large damage to carrots, high harvesting costs, time-consuming and labor-intensive, etc., and achieves the effect of strong work adaptability and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

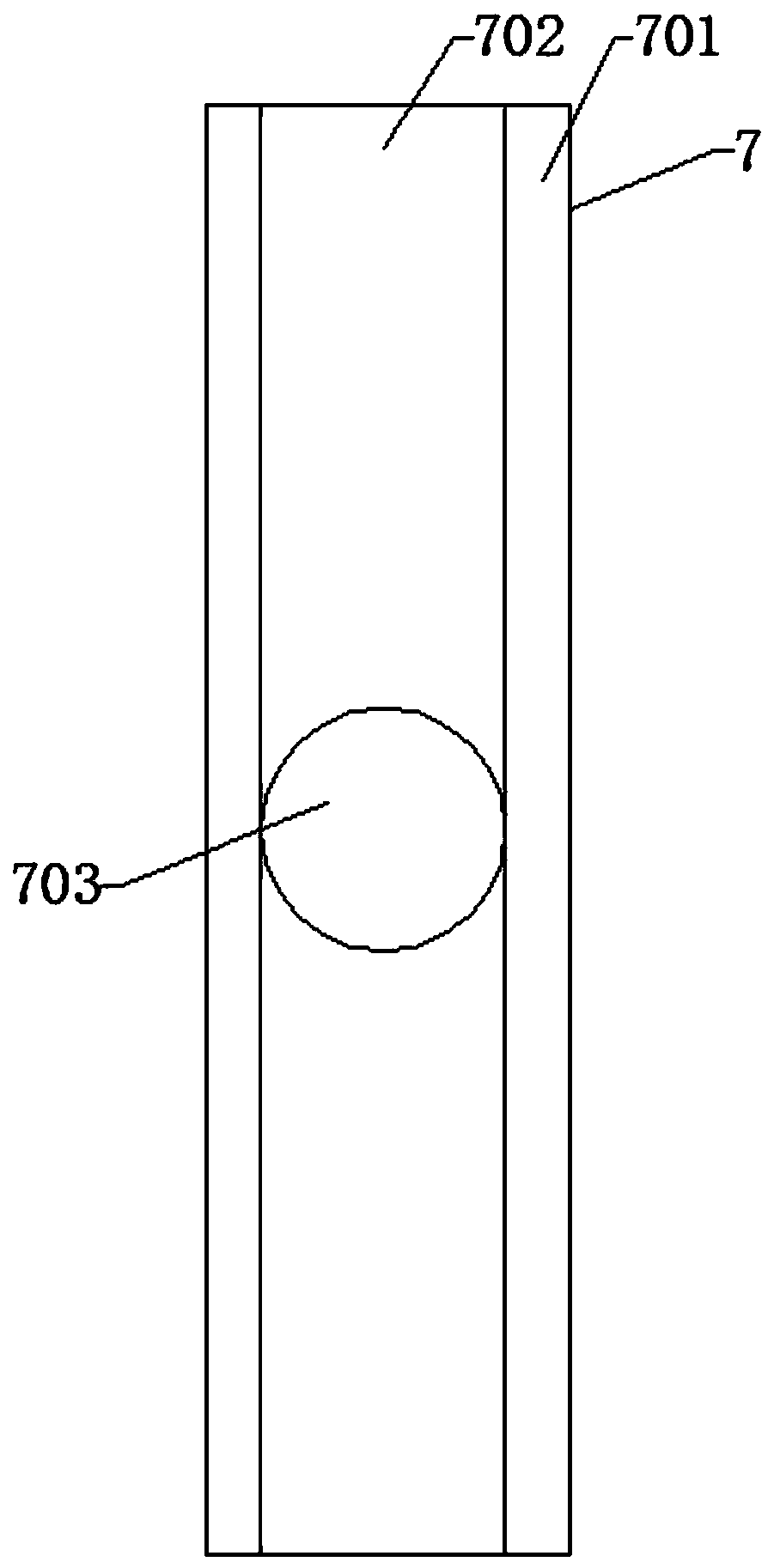

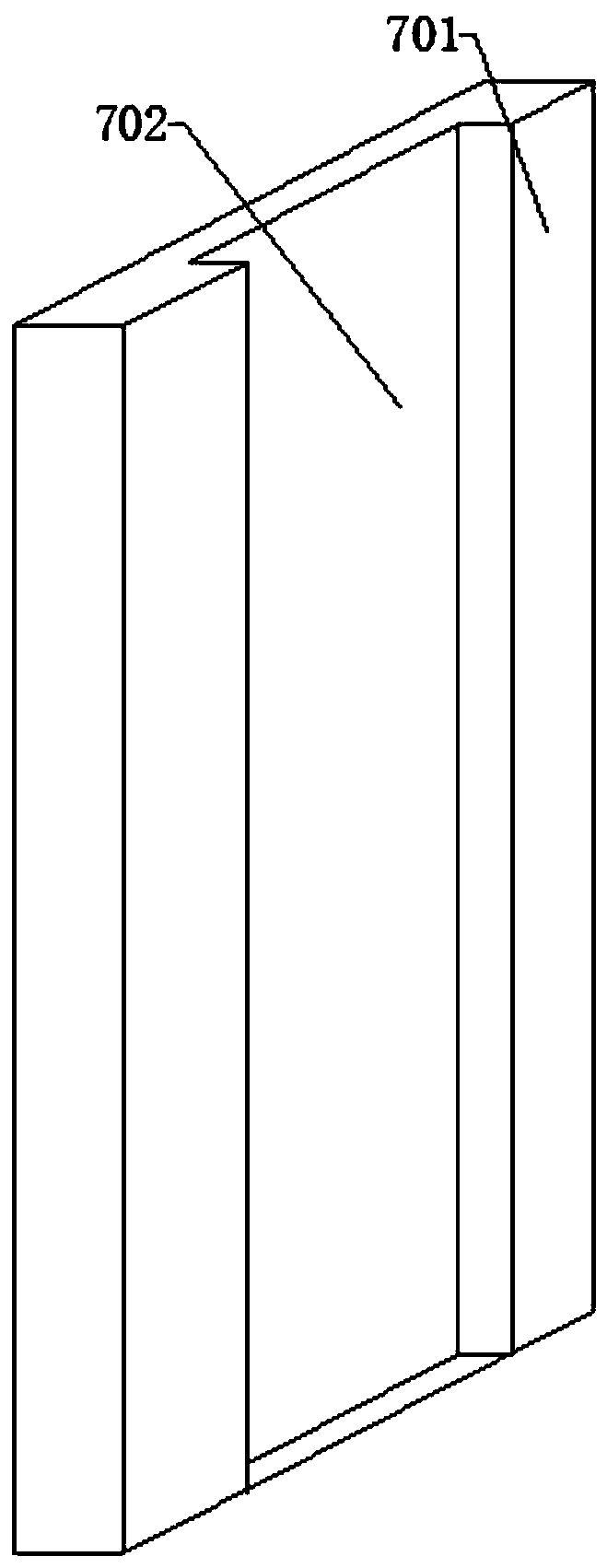

[0025] like Figure 1-Figure 6 As shown, a ridge planting carrot harvester includes a depth-limiting wheel 1, a vehicle frame 2, a first baffle plate 4, a first transmission shaft 6, and a support frame 7, and the rear end of the bottom of the vehicle frame 2 is provided with the Depth limiting wheel 1, the first baffle plate 4 is installed on both sides of the vehicle frame 2, a vibrating wheel 3 is provided on one side of the vehicle frame 2 near the bottom of the first baffle plate 4, and the vehicle frame 2 There is a sieve bar 5 between them, the bottom front end of the vehicle frame 2 is provided with the first transmission shaft 6, the end of the support frame 7 is coaxially connected with the suspension head 9, and the support frame 7 is installed on the vehicle frame 2 front top, a shearing head 8 is provided between the support frame 7, a conveyor belt 10 is provided on the rear side of the shearing head 8, and a second baffle 11 is installed on the two adjacent side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com