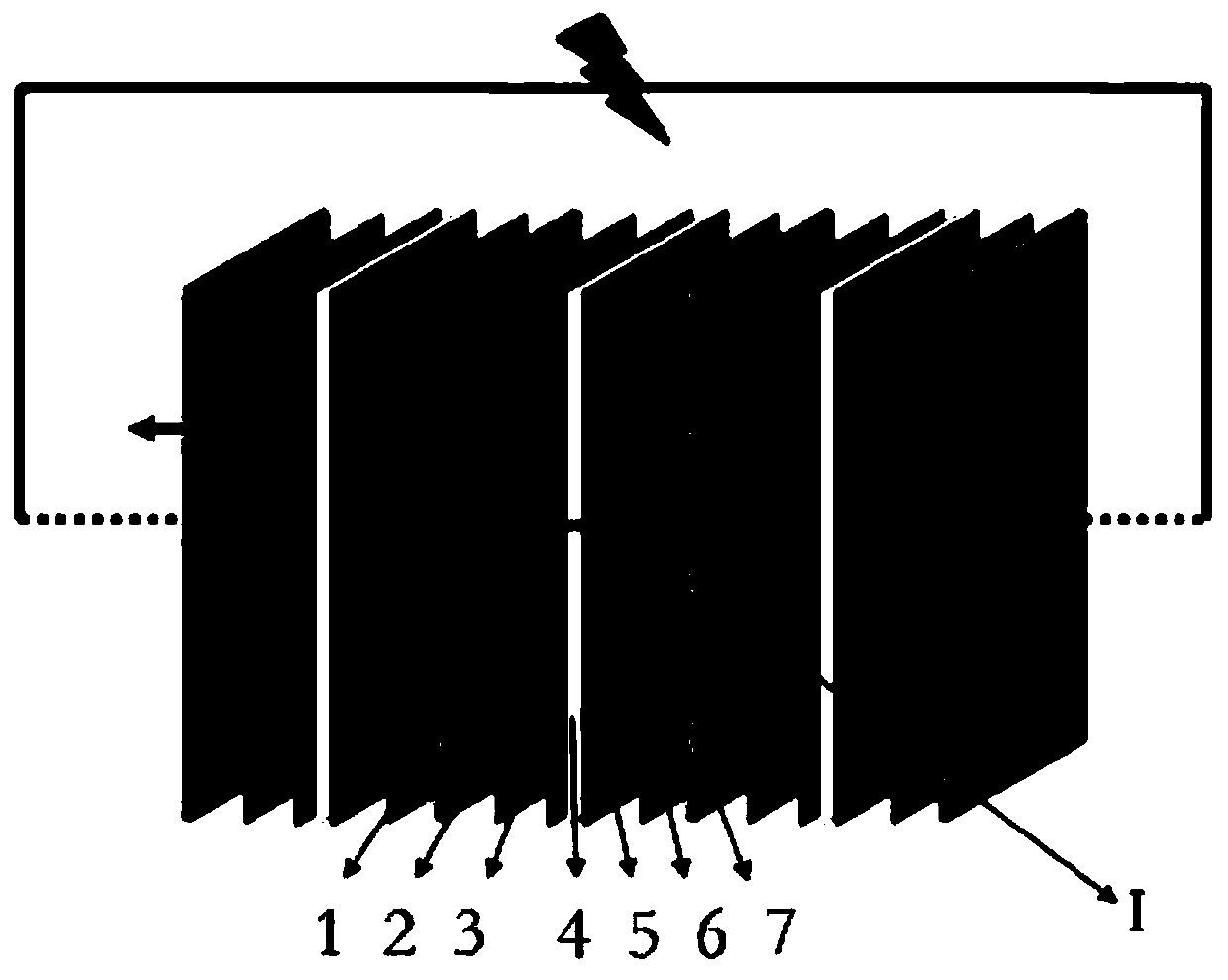

Fuel cell using diffusion layer as collector

A fuel cell and diffusion layer technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of reducing internal resistance, high cost, and increasing the optional range of component materials, and achieves the advantages of convenient operation, appropriate thickness, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

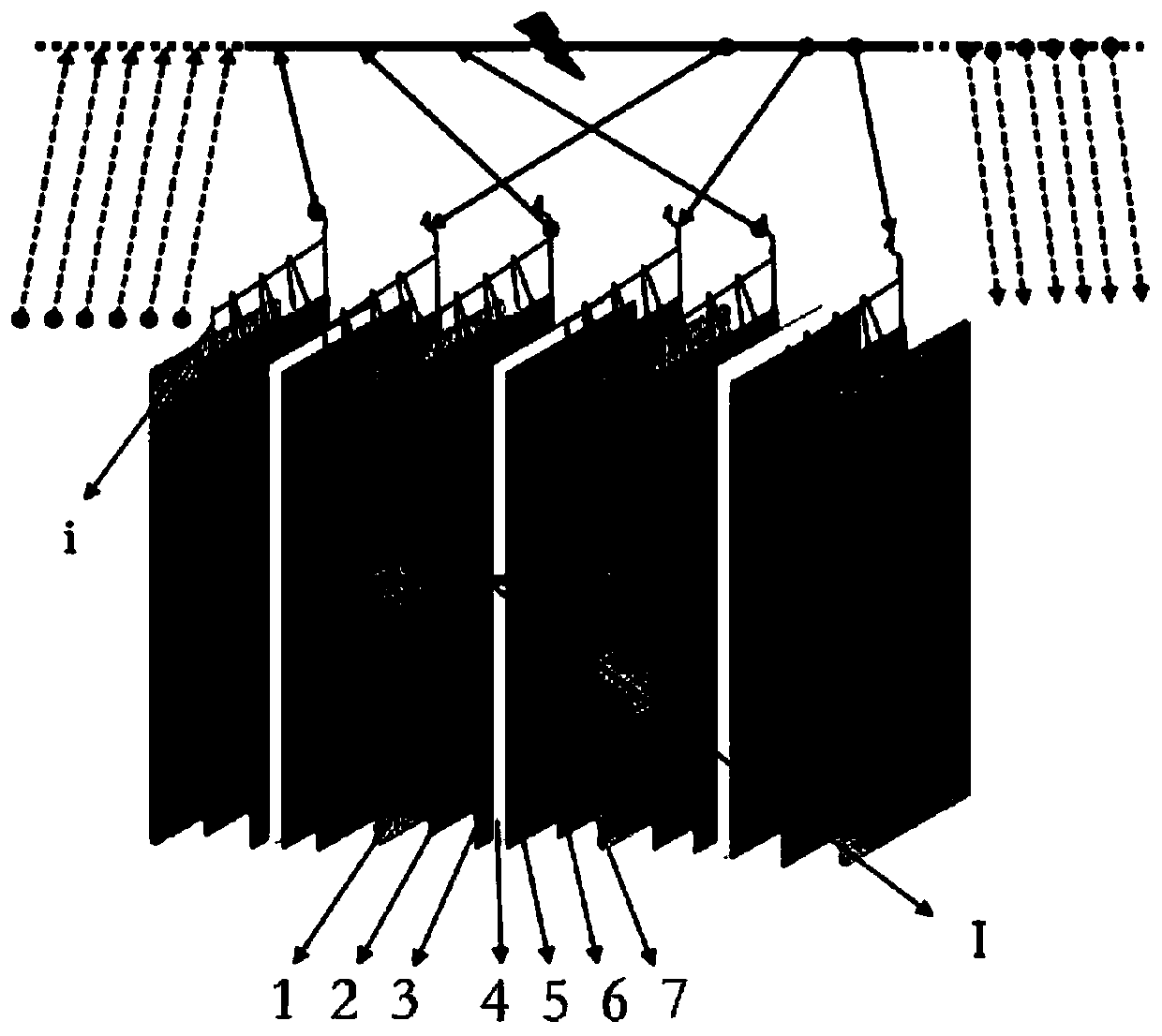

Embodiment 1

[0020] A commercially available platinum-carbon catalyst and a proton membrane with a thickness of 150 um were selected, and the membrane electrode was prepared by the CCM process and processed after molding for future use. During the preparation of the carbon paper matrix, fiber metal wires with a diameter of 0.04 mm such as image 3 The shown uniform ambush is laid to 1 / 2 thickness of the carbon paper, integrally formed, and then a microporous layer is prepared on one side of the carbon paper substrate. In order to prevent the soft wire electrode from piercing the proton membrane and causing a short circuit, a hard plastic film made of ABS material is hot-pressed along the outer edge of the proton membrane, and a 0.5mm thick gas introduction flow channel is made of molded phenolic resin powder. The repeating unit is sealed The ring is packaged into a short stack designed to be 1MPa, and the test result is a peak power of 1.2MPa. The cost is 40% lower than that of traditiona...

Embodiment 2

[0022] A commercially available platinum-carbon catalyst and a proton membrane with a thickness of 120 um were selected, and the membrane electrode was prepared by the CCM process and processed after molding for future use. During the preparation of the carbon paper matrix, fiber metal wires with a diameter of 0.04 mm such as image 3 The shown uniform ambush is laid to 1 / 3 of the thickness of the carbon paper, integrally formed, and then a microporous layer is prepared on one side of the carbon paper substrate. In order to prevent the soft wire electrode from piercing the proton membrane and causing a short circuit, a hard plastic film made of PVC is hot-pressed along the outer edge of the proton membrane, and a 0.8mm thick gas introduction flow channel is made of molded reinforced polypropylene hydrocarbon-filled composite resin, repeating the unit It is packaged into a short stack designed to be 1MPa with a sealing ring, and the test result is a peak power of 1.1MPa. The c...

Embodiment 3

[0024] A commercially available platinum-carbon catalyst and a proton membrane with a thickness of 180um were selected to prepare a membrane electrode by CCM technology, which was molded and processed for later use. During the preparation of the carbon paper matrix, fiber metal wires with a diameter of 0.04 mm such as image 3 The shown uniform ambush is laid to 1 / 3 of the thickness of the carbon paper, integrally formed, and then a microporous layer is prepared on one side of the carbon paper substrate. In order to prevent the soft wire electrode from piercing the proton membrane and causing a short circuit, a hard plastic film made of POM is hot-pressed along the outer edge of the proton membrane, and a 0.8mm thick gas introduction flow channel is made of molded reinforced polyurethane. The repeating unit is sealed The ring is packaged into a short stack designed to be 1MPa, and the test result is a peak power of 1.15MPa. The cost is 30% lower than that of traditional fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com