Electrode plate automatic tidying device

A sorting device and automatic sorting technology, applied in the directions of transportation and packaging, stacking of objects, conveyors, etc., can solve the problems of low efficiency and high labor cost of plates, reduce labor production costs, and improve plate stacking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

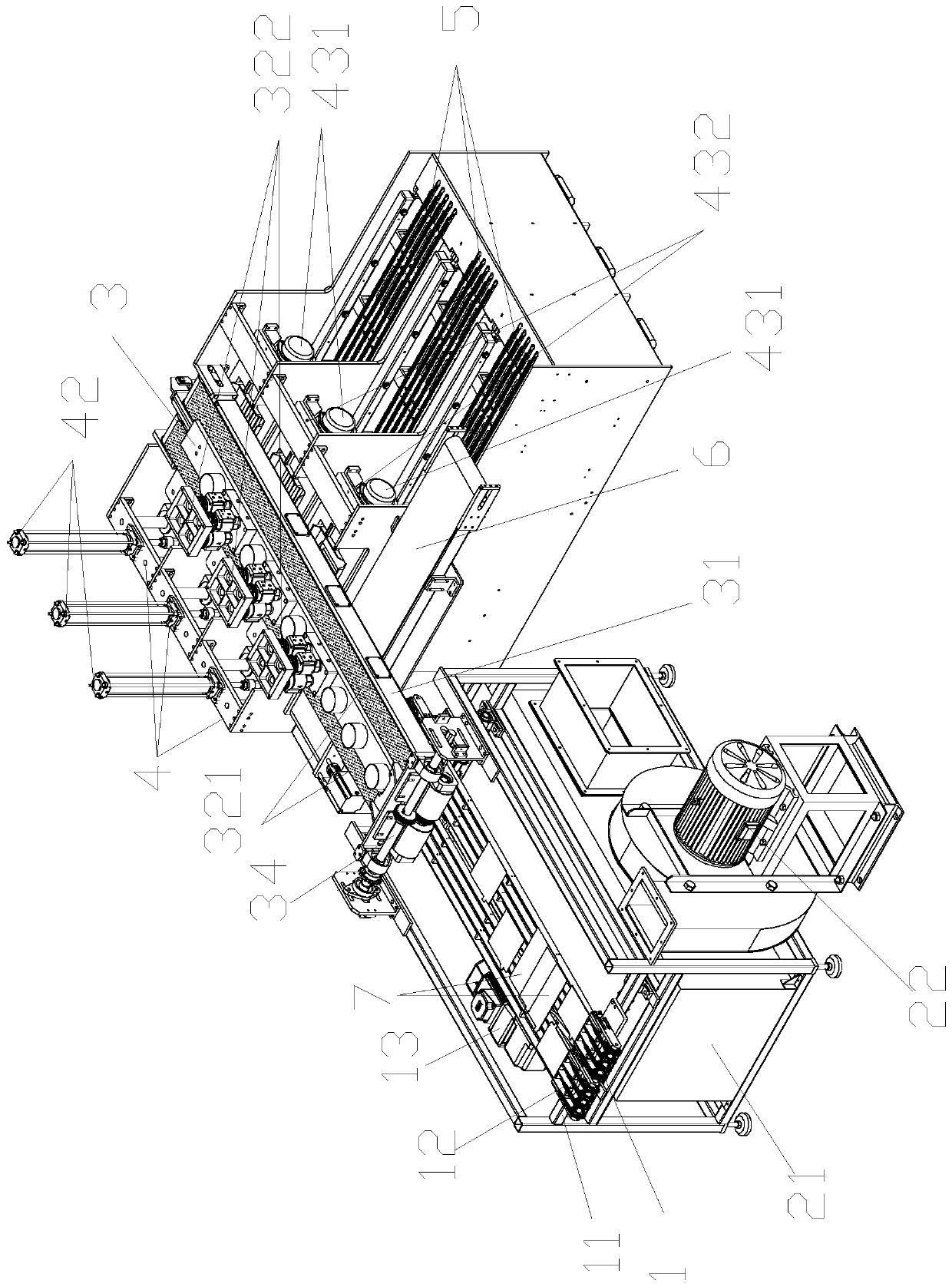

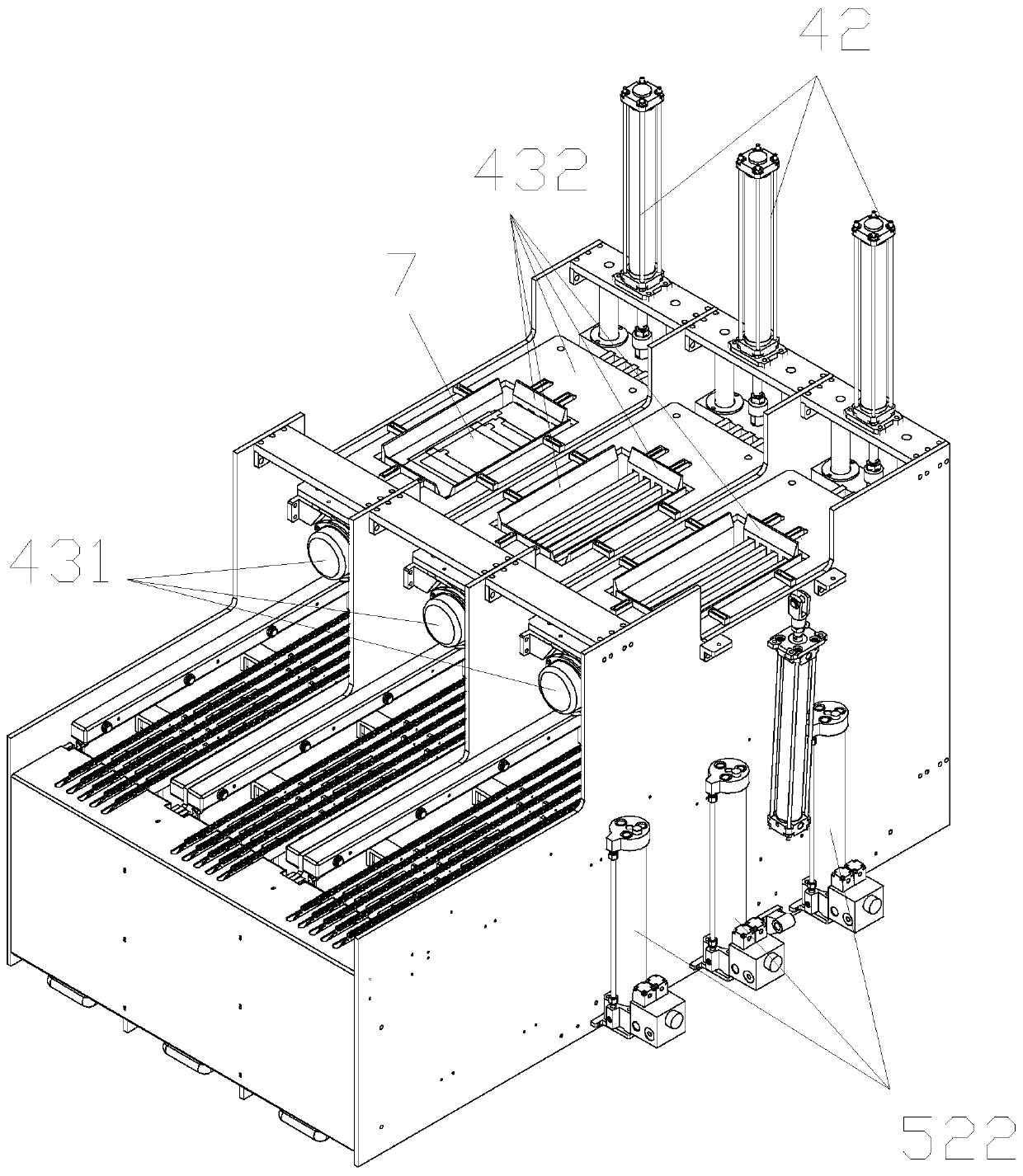

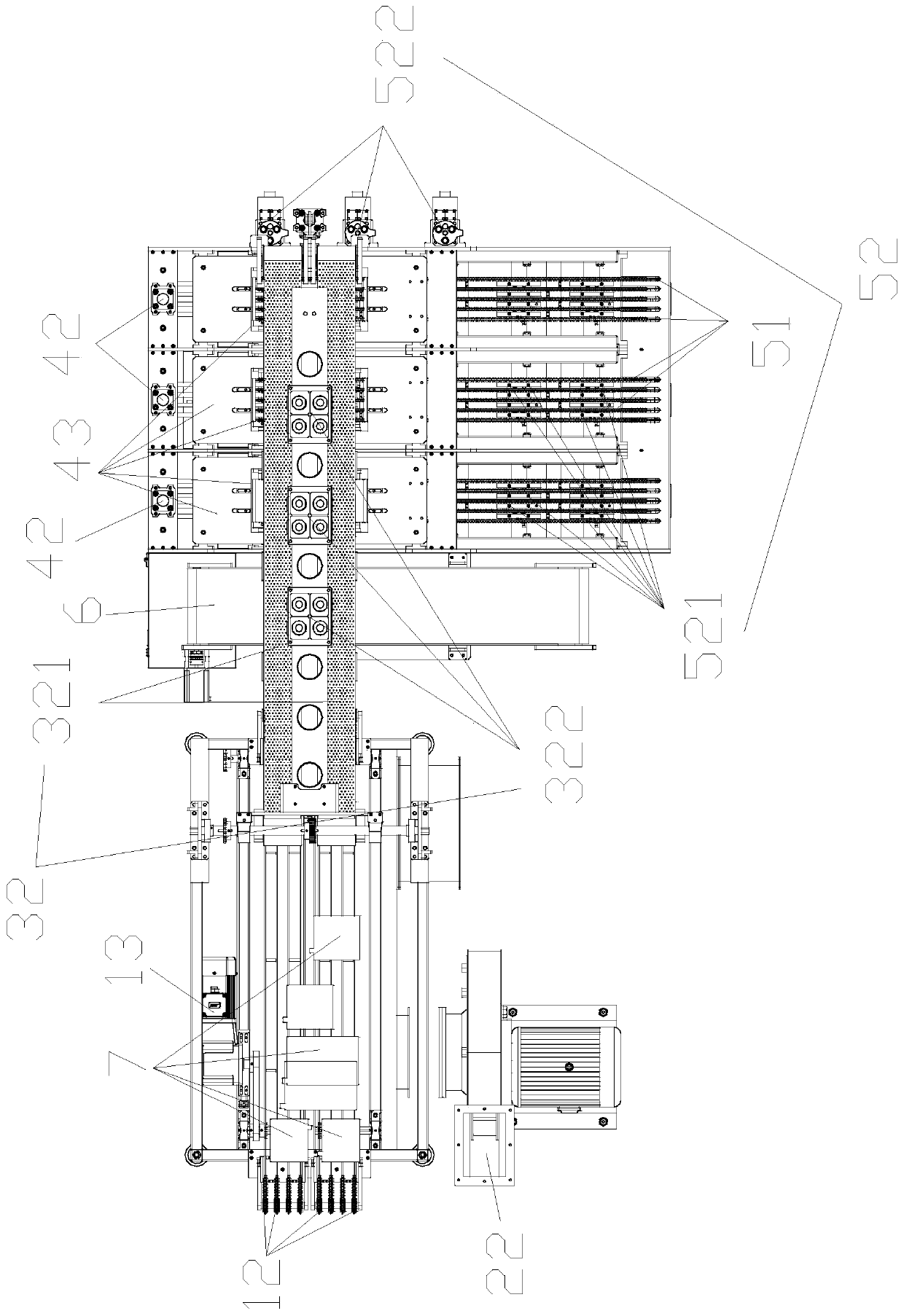

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, in the embodiment of the present invention, an automatic electrode plate finishing device includes: a first conveying mechanism 1, which sequentially conveys at least one row of single-layered electrode plates 7; a second conveying mechanism 3, suspended on the first Above the downstream of the conveying mechanism 1 and rotates synchronously with the first conveying mechanism 1, sequentially absorbing a single pole plate 7 on the downstream position conveyed by the first conveying mechanism 1 and conveying the pole plate 7 to the next mechanism; the receiving mechanism 4, It can be arranged under the second conveying mechanism 3 in a liftable manner, and is used to collect and organize the single pole plates 7 put in by the second conveying mechanism 3 to form a pole plate cluster, which is then transported to the next mechanism; the third conveying mechanism 5 is set Below the material receiving mechanism...

Embodiment 2

[0048] The difference between the electrode plate automatic arrangement device of the second embodiment and the first embodiment is that a buffer conveying mechanism 6 is provided after the first conveying mechanism 1 and before the material receiving mechanism 4 . The buffer conveying mechanism 6 is arranged below the second conveying mechanism 3 . When a special situation occurs (such as equipment failure, the pole plate 7 cannot be normally put into the material receiving mechanism 4, the pole plate cluster cannot be normally transferred by the third conveying mechanism 5, etc.), the second conveying mechanism 3 will be in the buffer conveying mechanism 6. A single pole plate 7 is put in order from above, and then the single pole plate 7 is transported by the buffer conveying mechanism 6 in an emergency, which avoids damage to the pole plate 7 that is subsequently transported due to the above-mentioned special circumstances, and stops the loss in time to avoid increasing the...

Embodiment 3

[0051] The difference between the electrode plate automatic sorting device of Embodiment 3 and Embodiment 1 is that the number of horizontal conveying assemblies 12 in the first conveying mechanism 1 is different.

[0052] In the embodiment of the present invention, the first conveying mechanism 1 includes: a first conveying bracket 11 ; Specifically, the first driving assembly 13 is in transmission connection with the cylindrical rotating transmission member, and is used to drive the two horizontal conveying assemblies 12 to rotate synchronously; at least two horizontal conveying assemblies 12 are rotatably arranged in parallel on the first conveying bracket 11, It is used to convey the pole plate 7 on the horizontal conveying assembly 12 . In the embodiment of the present invention, two horizontal conveying assemblies 12 are provided on the first conveying bracket 11 . The same end at the upstream of the two horizontal conveying assemblies 12 shares a cylindrical rotating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com