Surface treatment method of stainless steel pipe fittings

A surface treatment, stainless steel technology, applied in the direction of grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of pipe surface damage, pipe surface scratches, pipe use influence, etc., to ensure normal use, The effect of reducing the difficulty of repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

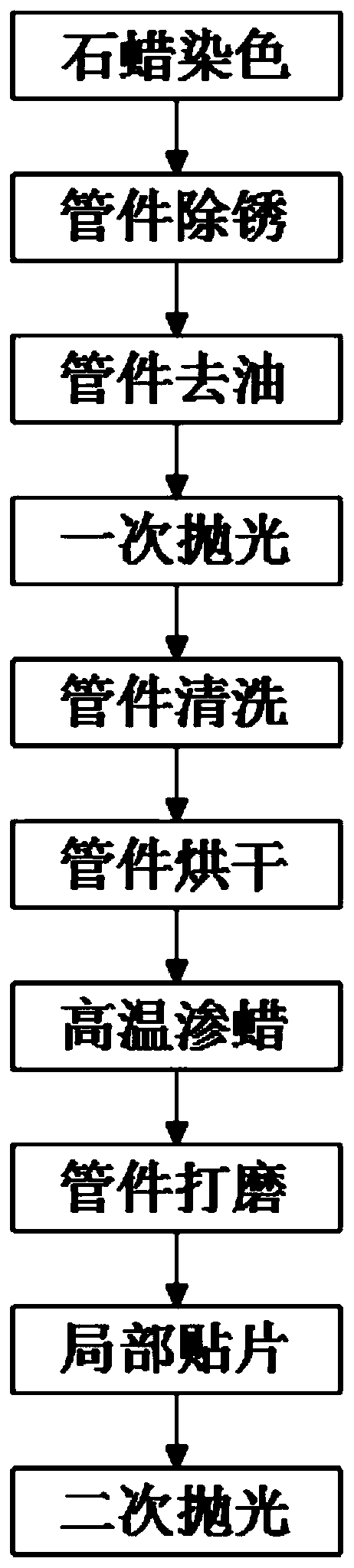

[0026] The present invention provides such figure 1 A surface treatment method for stainless steel pipe fittings shown specifically includes the following steps:

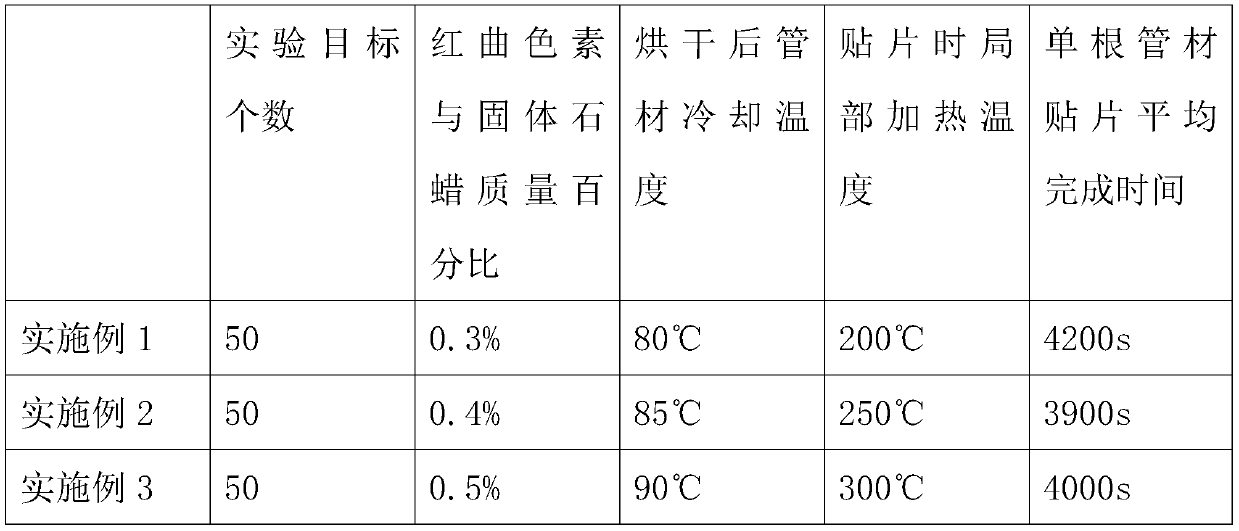

[0027] Step 1, paraffin wax dyeing: adding solid paraffin raw materials into the sealed reaction kettle, and adding monascus pigment into the inside of the sealed reaction kettle at the same time, the mass percentage of monascus pigment and solid paraffin wax is 0.3%, and then heating for 10 minutes at a heating temperature of 150 degrees Celsius. Stirring is continued during the heating process, so that the monascus pigment and solid paraffin are effectively mixed, and after the heating is completed, it is left to cool to obtain red paraffin;

[0028] Step 2. Rust removal of pipe fittings: use a cloth wheel polishing machine to derust the surface of the stainless steel pipe, and set the processing time to 7 minutes so that the surface roughness of the pipe is less than or equal to 0.5um;

[0029] Step 3. Degreasin...

Embodiment 2

[0039] The present invention provides such figure 1 A surface treatment method for stainless steel pipe fittings shown specifically includes the following steps:

[0040] Step 1, paraffin wax dyeing: add the solid paraffin raw material into the sealed reaction kettle, and add the red yeast rice pigment to the inside of the sealed reactor at the same time, the mass percentage of the red yeast rice pigment and the solid paraffin wax is 0.4%, and then heat for 13 minutes at a heating temperature of 160 degrees Celsius. Stirring is continued during the heating process, so that the monascus pigment and solid paraffin are effectively mixed, and after the heating is completed, it is left to cool to obtain red paraffin;

[0041] Step 2, rust removal of pipe fittings: use a cloth wheel polishing machine to derust the surface of the stainless steel pipe, and set the processing time to 8 minutes, so that the surface roughness of the pipe is less than or equal to 0.5um;

[0042] Step 3. ...

Embodiment 3

[0052] The present invention provides such as figure 1 A surface treatment method for stainless steel pipe fittings shown specifically includes the following steps:

[0053] Step 1, paraffin wax dyeing: add solid paraffin raw materials into the sealed reaction kettle, and add monascus pigment into the inside of the sealed reaction kettle at the same time, the mass percentage of monascus pigment and solid paraffin wax is 0.5%, and then heat for 15 minutes at a heating temperature of 170 degrees Celsius. Stirring is continued during the heating process, so that the monascus pigment and solid paraffin are effectively mixed, and after the heating is completed, it is left to cool to obtain red paraffin;

[0054] Step 2. Rust removal of pipe fittings: Use a cloth wheel polisher to derust the surface of the stainless steel pipe. The processing time is set to 9 minutes, so that the surface roughness of the pipe is less than or equal to 0.5um;

[0055] Step 3. Degreasing the pipe fitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com