A method of manufacturing an electromagnetic shielding sheet

A manufacturing method and electromagnetic shielding technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problem that the thickness of the electromagnetic shielding sheet is not suitable for small electronic equipment, and achieve the effect of miniaturization and reduction of space thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

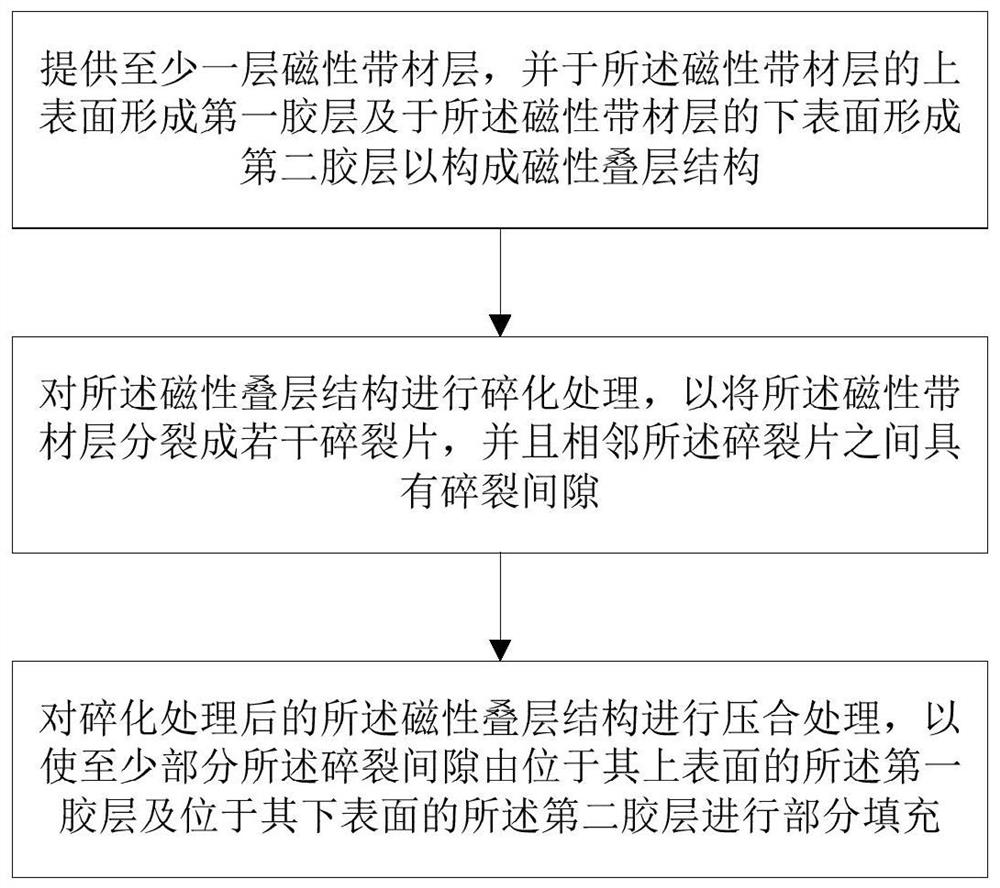

[0043] Such as figure 1 As shown, the present embodiment provides a manufacturing method of an electromagnetic shielding sheet, the manufacturing method comprising:

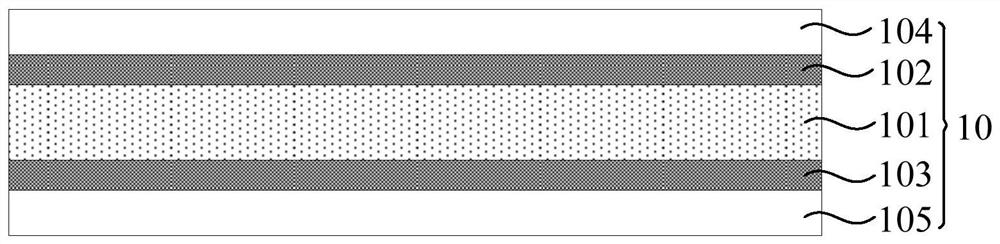

[0044] A magnetic tape layer 101 is provided, and a first adhesive layer 102 is formed on the upper surface of the magnetic tape layer 101 and a second adhesive layer 103 is formed on the lower surface of the magnetic tape layer 101 to form a magnetic stack structure 10;

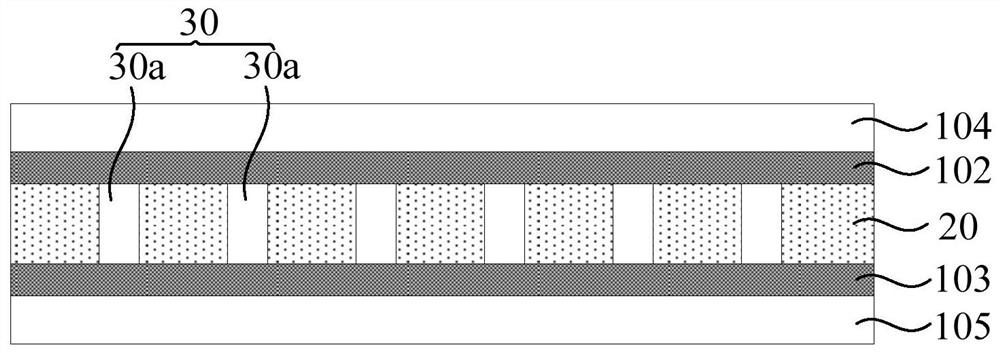

[0045] Fragmenting the magnetic laminated structure 10 to split the magnetic tape layer 101 into several fragments 20, and there are fragmentation gaps 30 between adjacent fragments 20;

[0046] The crushed magnetic laminated structure 10 is pressed, so that at least part of the fragmented gap 30 is formed by the first adhesive layer 102 on the upper surface and the first adhesive layer 102 on the lower surface. The second glue layer 103 is partially filled.

[0047] Please combine below figure 1 , see Figure 2 to Figure 4d The method for...

Embodiment 2

[0068] Such as figure 1 As shown, the present embodiment provides a manufacturing method of an electromagnetic shielding sheet, the manufacturing method comprising:

[0069] Provide at least two layers of magnetic tape layers 101, and form a third adhesive layer 106 between adjacent magnetic tape layers 101, and form a first adhesive layer 102 on the upper surface of the above structure and on the lower surface of the above structure forming a second adhesive layer 103 to form the magnetic stack structure 10;

[0070] Fragmenting the magnetic laminated structure 10 to split the magnetic tape layer 101 into several fragments 20, and there are fragmentation gaps 30 between adjacent fragments 20;

[0071] The crushed magnetic laminated structure 10 is subjected to a pressing process, so that at least part of the fragmented gap 30 is formed by the first adhesive layer 102 or the third adhesive layer 106 and The second adhesive layer 103 or the third adhesive layer 106 located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com