Multi-linkage mechanism and linkage moving door

A linkage mechanism and linkage door technology, applied in the direction of windows/doors, building components, door/window accessories, etc., can solve problems such as unstable movement, noise, derailment, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

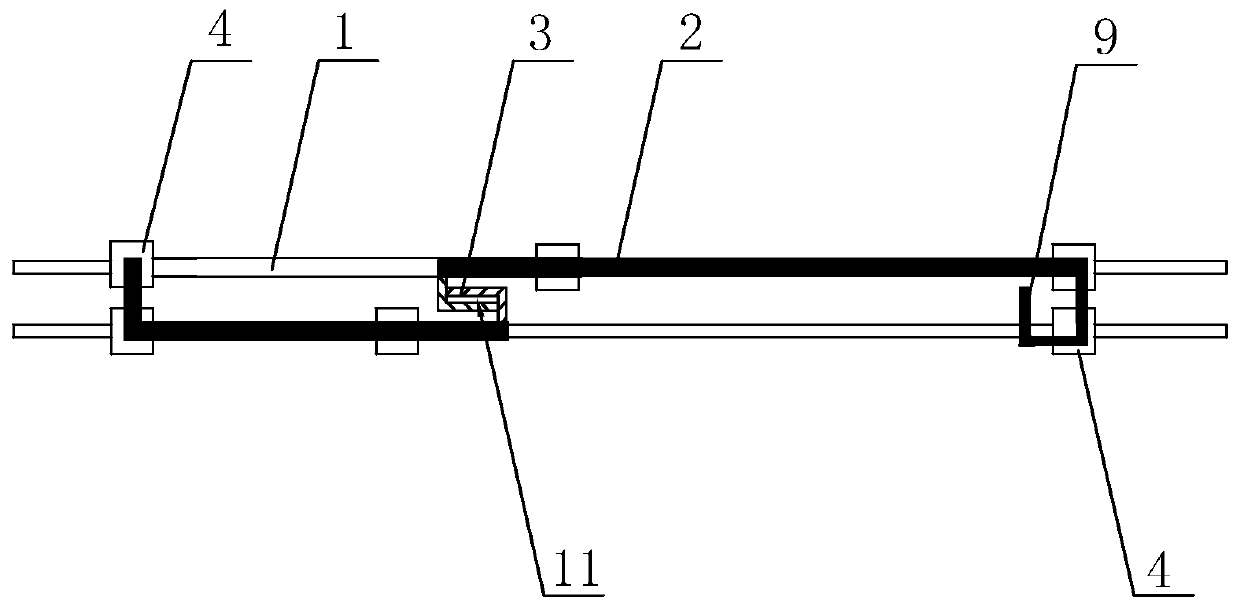

[0052] linkage moving door, such as figure 1 As shown, it includes two sliding rails 1 fixed parallel to each other. The two sliding rails 1 are connected to the linkage door 2 through roller sliding. The sliding rail 1 is parallel to the surface of the linkage door 2, and the two linkage doors 2 are installed adjacent to each other. There is a linkage hook 3 for realizing linkage. The linkage hook 3 is the prior art. After the linkage hook 3 overlaps, there is a transmission gap 11 between the two linkage hooks 3, so that the transmission between the linkage doors 2 is smoother. The side of the interlocking door 2 close to the outer side of the interlocking door 2 is integrally folded to form a folded edge 9. Since the opening of the hand slot 9 does not occupy the external space, the structure is more compact; the inner interlocking door 2 is wider than the outer interlocking door 2. Easy access to hem9. When in use, pull the inner linkage door 2 to slide through the folde...

Embodiment 2

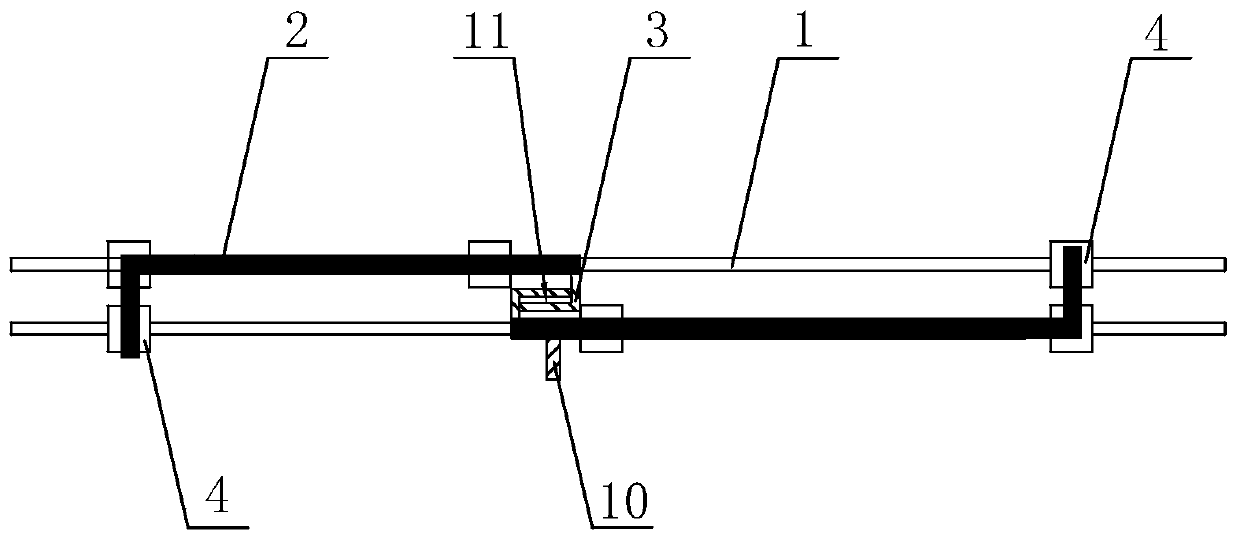

[0055] linkage moving door, such as figure 2 As shown, the difference from Embodiment 1 is that the two interlocking doors 2 are mirrored on the two slide rails 1, and the side of the outer interlocking door 2 far away from the inner interlocking door 2 is fixed to facilitate pulling the outer interlocking door 2. The outer handle 10 is convenient for the linkage door 2 to completely overlap to achieve the maximum door opening.

Embodiment 3

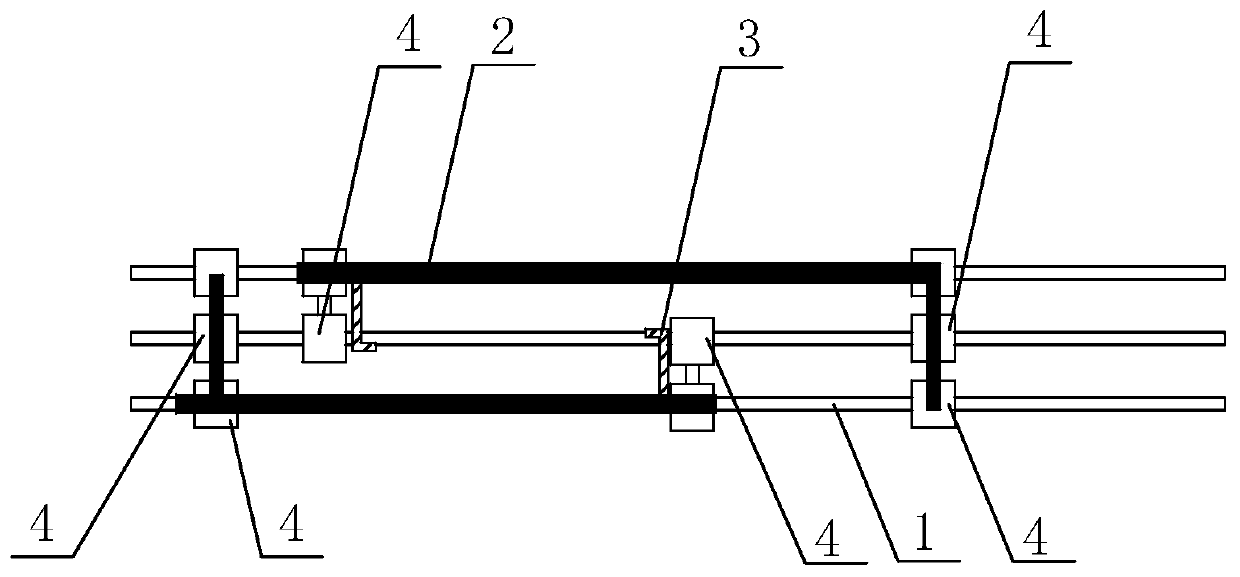

[0057] linkage moving door, such as image 3 As shown, the difference from Embodiment 1 is that the three slide rails 1 arranged parallel to each other are slidingly connected with the linkage door 2 on the slide rails 1 on both sides, and two Sliding piece 4, the sliding piece 4 is a roller, and the two rollers are slidingly connected to two adjacent slide rails 1 respectively, and a sliding piece 4 is fixed at the end of the linkage door 2 close to each other, and the sliding piece 4 slides It is connected to the sliding rail 1 in the middle, and by increasing the number of sliding rails 1 and sliding parts 4, the sliding stability of the linkage door 2 is further improved, the sliding noise is low, and the door opening feeling is more comfortable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com