A light-weight anechoic chamber cone material and its preparation method

A sharp cone and darkroom technology, applied in the field of wave-absorbing materials, can solve the problems of being unsuitable for outdoor use, low mechanical strength, and poor heat resistance, and achieve the effects of easy folding, shrinking, storage and storage, high mechanical strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: 300mm high 120°C light-weight anechoic chamber tip material for long-term use

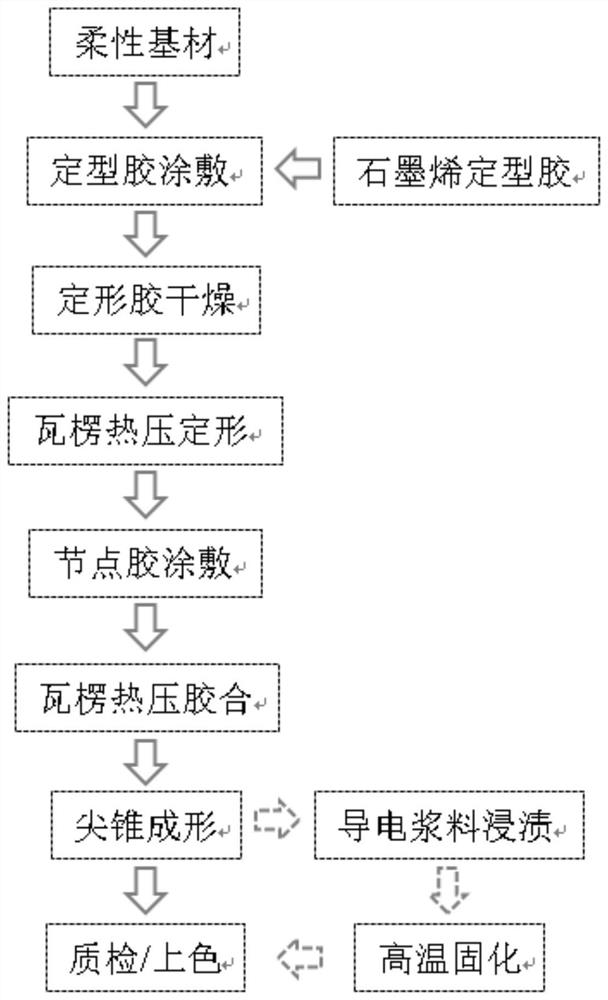

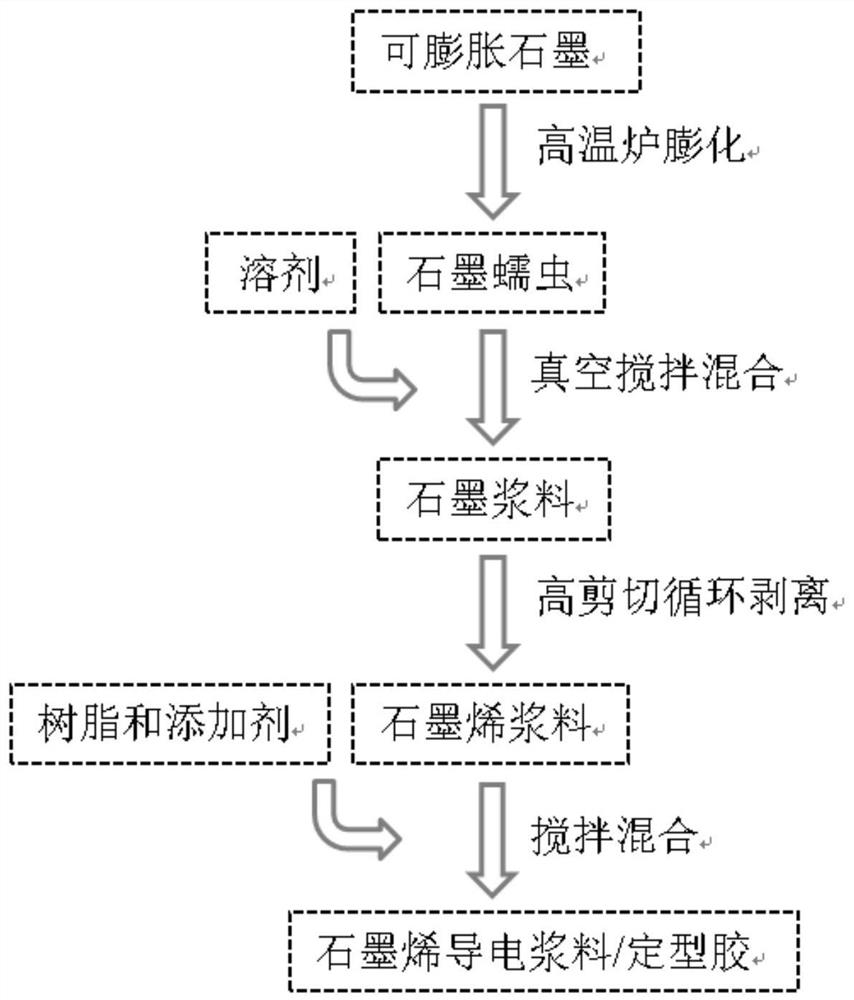

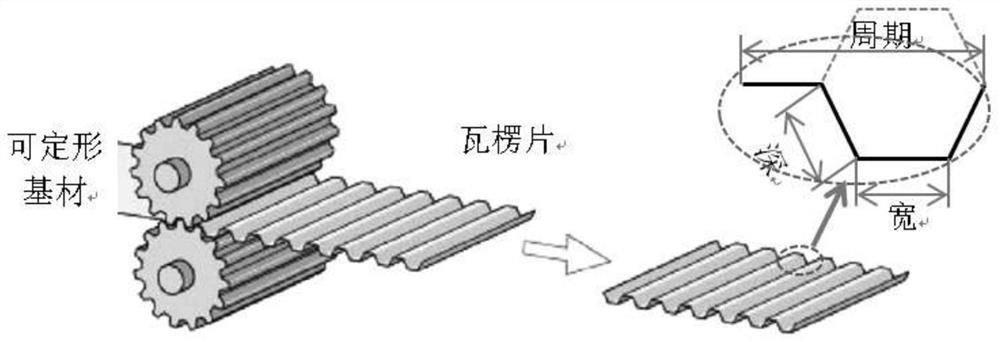

[0048] (1) Production process such as figure 1 As shown, firstly, the honeycomb cone structure is optimized by electromagnetic simulation, and the flexible substrate is determined to have an area density of 110g / m 2 The flame-retardant kraft paper is made of flame-retardant kraft paper, the conductive wave-absorbing agent is graphene, and the resin is water-soluble phenolic formaldehyde; according to the electromagnetic simulation design, the total height H of the honeycomb is 300mm, the height of the cone is 220mm, and the bottom width D is 100mm. Performance, using oblique honeycomb, the angle of the honeycomb and the opening forms a 15° angle, a layer of corrugated honeycomb is a positive 15° angle, and its upper and lower sides are a negative 15° angle, forming an alternate superposition of positive and negative 15° angles to ensure the best performance symmetry. The side le...

Embodiment 2

[0056] Example 2: 500mm high 300°C light-weight anechoic chamber tip material for long-term use

[0057] (1) Production process such as figure 1 As shown, firstly, electromagnetic simulation is used to optimize the design of the honeycomb cone structure, and the flexible substrate is determined to have an area density of 200g / m 2 The conductive wave-absorbing agent is graphene, and the resin is modified silicone resin; according to the electromagnetic simulation design, the total height H of the honeycomb is 500mm, the height of the cone is 400mm, and the bottom width D is 150mm. Wave performance, using oblique honeycomb, the angle of the honeycomb and the opening forms a 15° angle, a layer of corrugated honeycomb is a positive 15° angle, and its top and bottom are negative 15° angles, forming an alternate superposition of plus and minus 15° angles to ensure performance of symmetry. The side length and depth of the honeycomb are both 5mm, and the surface resistance of the wa...

Embodiment 3

[0064] Example 3: 400mm high and 80°C long-term use of oblique-incidence wave-absorbing wedge honeycomb light-weight wave-absorbing anechoic chamber cone material (1) The production process is as follows figure 1 As shown, firstly, the honeycomb cone structure is optimized by electromagnetic simulation, and the flexible substrate is determined to have an area density of 60g / m 2 The polyester non-woven fabric (thickness 100μm), the conductive wave absorbing agent is graphene, and the resin is modified phenolic resin; according to the electromagnetic simulation design, the total height H of the honeycomb is 400mm, the height h of the cone is 300mm, and the bottom width D is 120mm , in order to improve the absorbing performance of oblique incidence, oblique honeycomb is used. One side of the honeycomb cone is at an angle of about 40°, and the other side is at an angle of 52°. The angle of the honeycomb and the opening forms an angle of 45°. The surface resistance of the wave-abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap