A power distribution box with heat dissipation function

A distribution box, functional technology, applied in the direction of electrical components, substation/switch layout details, substation/switchgear cooling/ventilation, etc., can solve the problem of discounting the explosion-proof performance of the distribution box, affecting the normal operation of the equipment in the distribution box, etc. problems, to achieve the effect of improving explosion-proof performance, avoiding adverse effects, reducing manufacturing costs and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

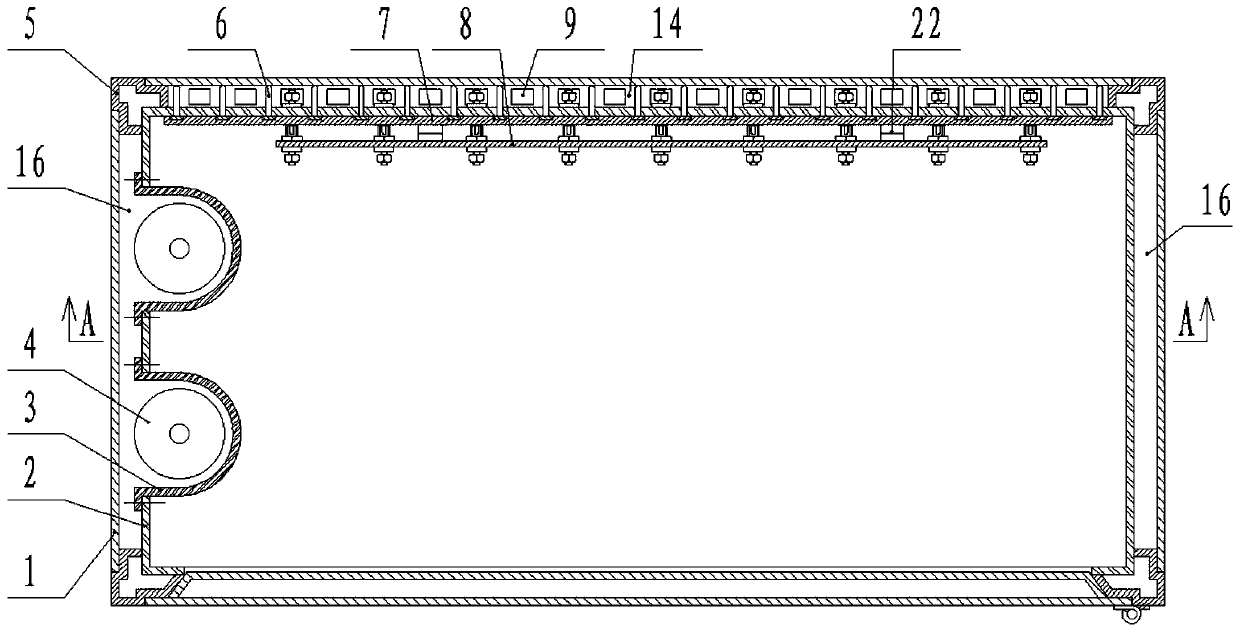

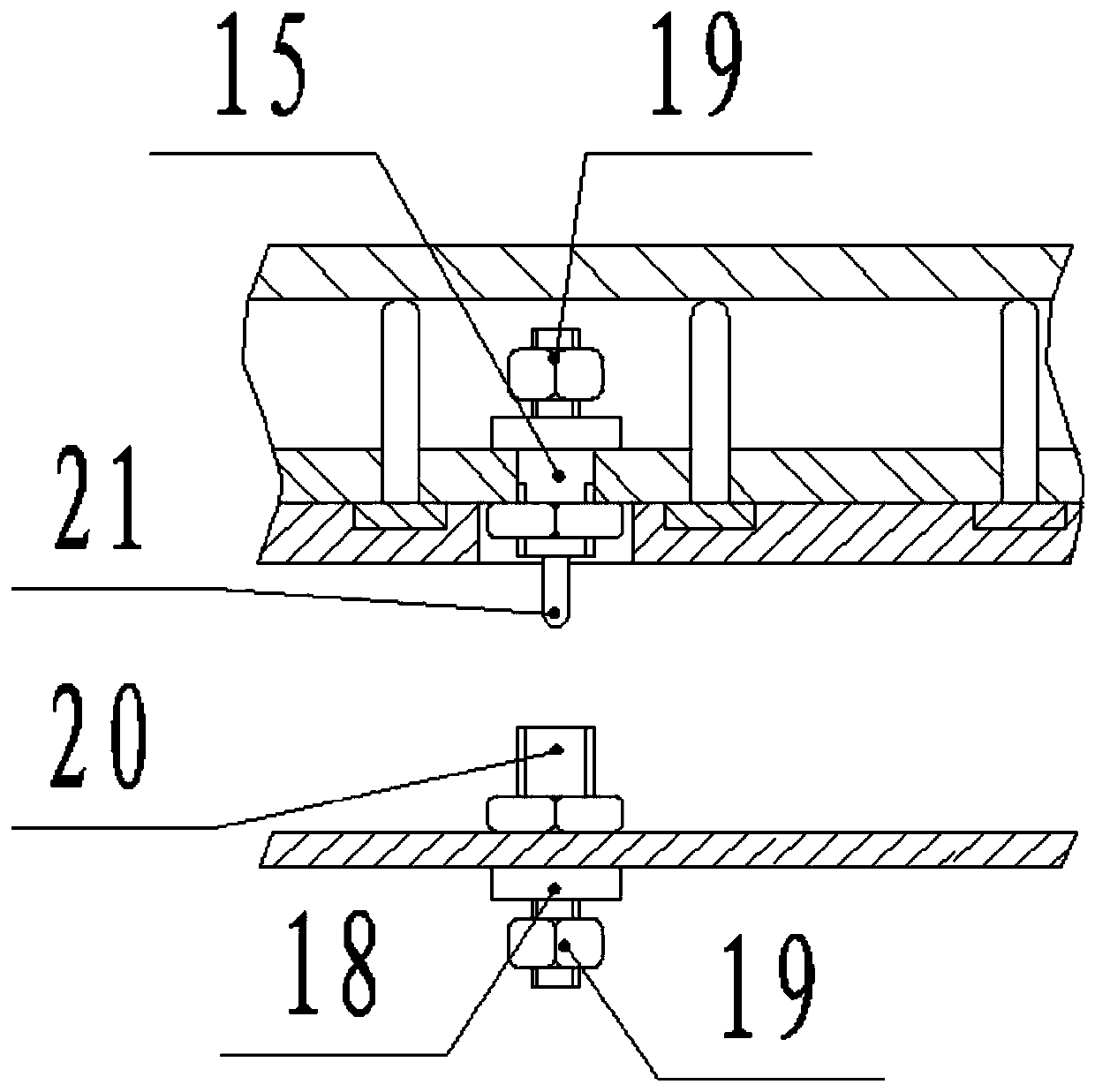

[0038] This embodiment includes a box body, a cooling fan 12 and a braking resistor 4. The cooling fan 12 and the braking resistor 4 are installed in the box body, and a fixing plate 8 for installing electrical components is arranged on the inner side of the back panel of the box body. The above are common structures in the prior art, and will not be repeated here.

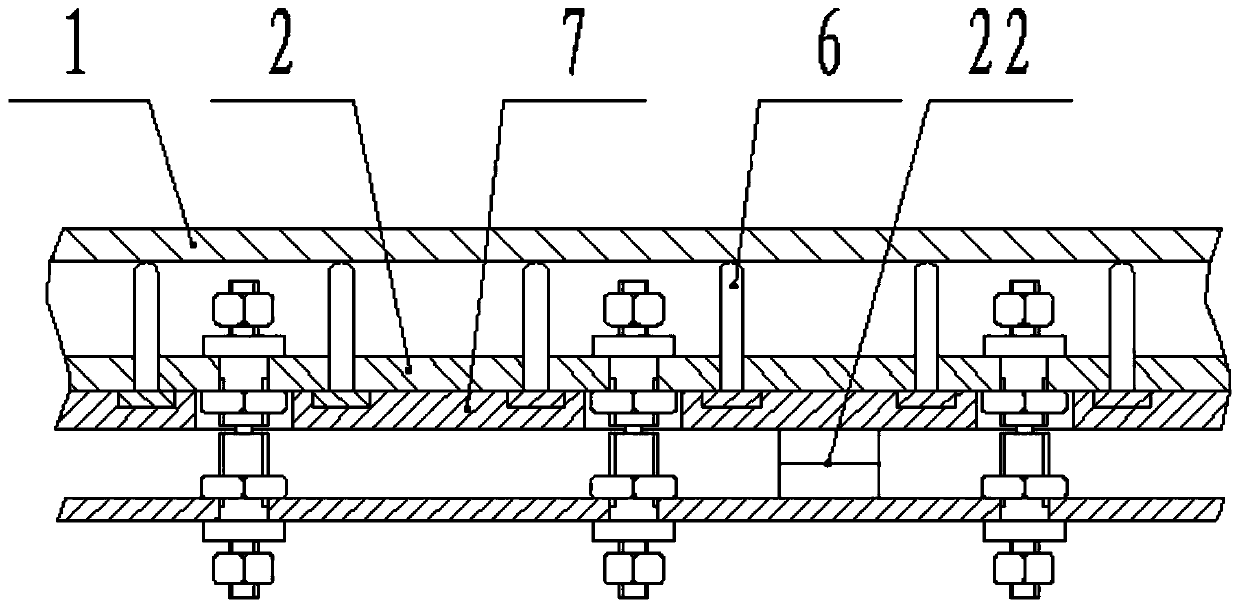

[0039] The box body is a double-layer structure, and the two-layer box body is called the inner layer box body 2 and the outer layer box body respectively. When dissipating heat, the heat in the distribution box is transferred to the interlayer between the inner box body 2 and the outer box body through heat transfer, and then dissipated to the outside of the distribution box by the cooling fan 12 .

[0040] The inner box 2 is a cubic structure surrounded by steel plates, and the outer sides of the four vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com