Ultrasonic imaging method for polymer bonded explosive surface crack detection and device

An ultrasonic imaging method and surface crack technology, which can be used in the analysis of solids using sonic/ultrasonic/infrasonic waves, and the processing of detected response signals, which can solve problems such as less research on crack imaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is further described in detail:

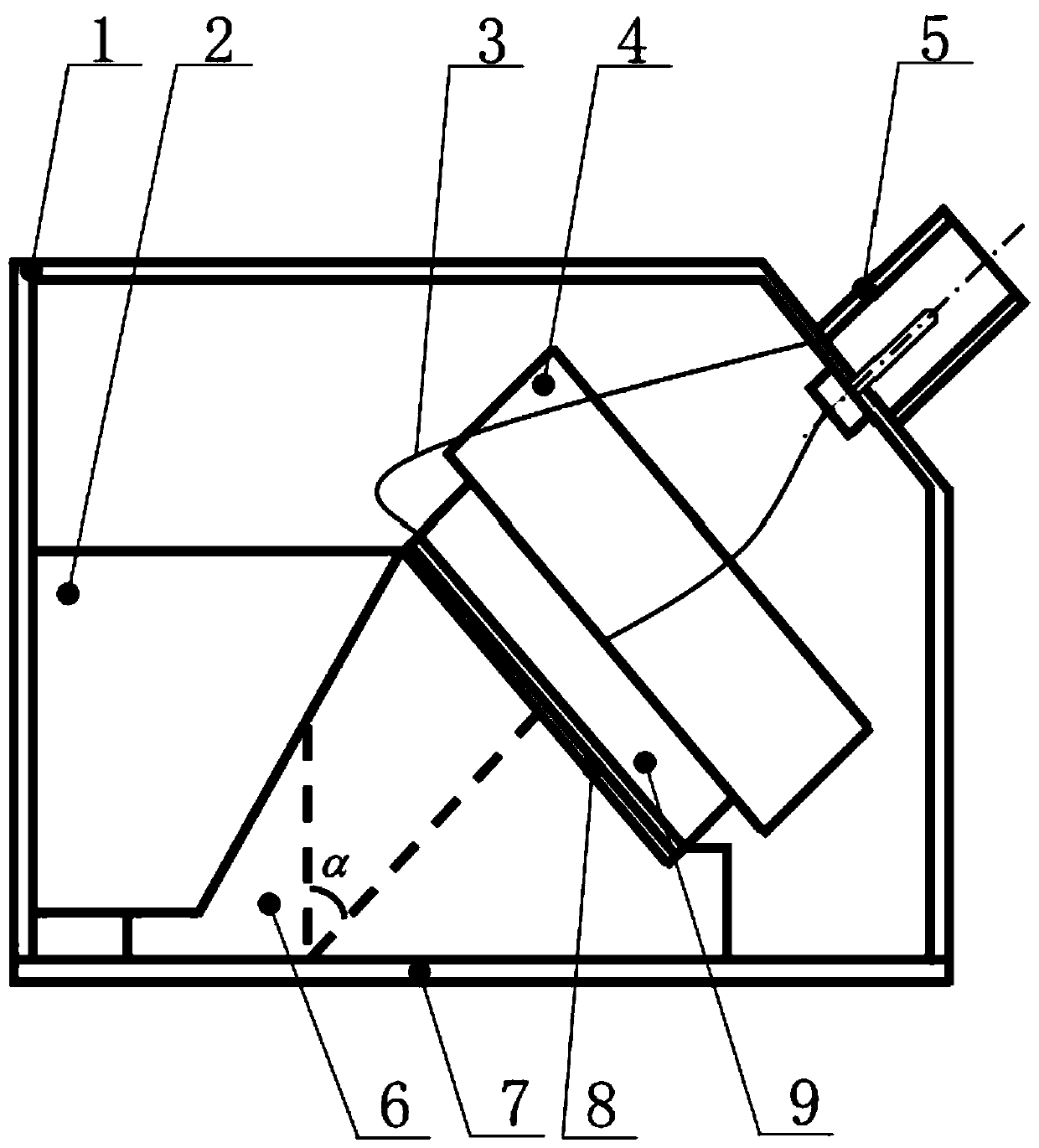

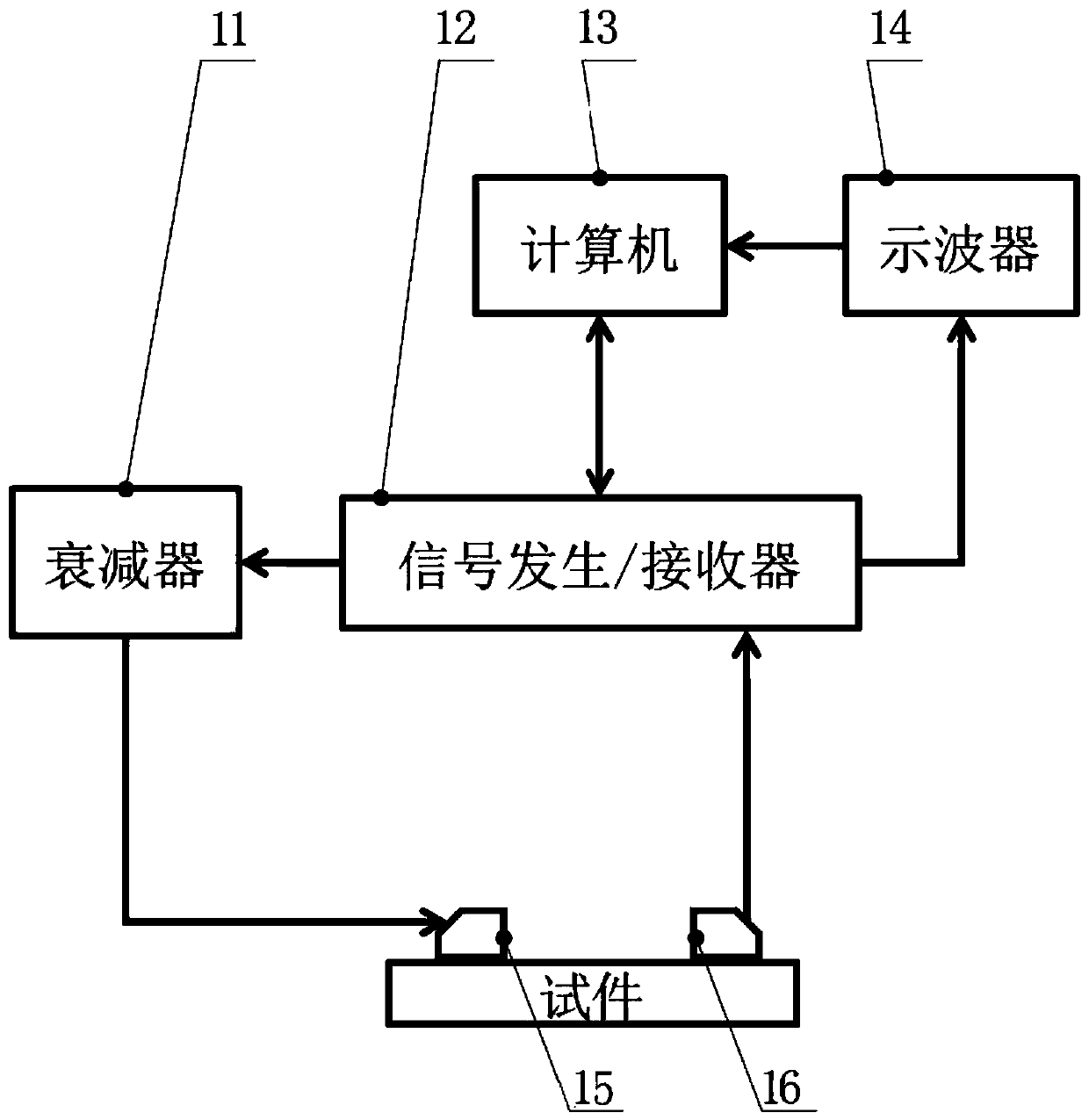

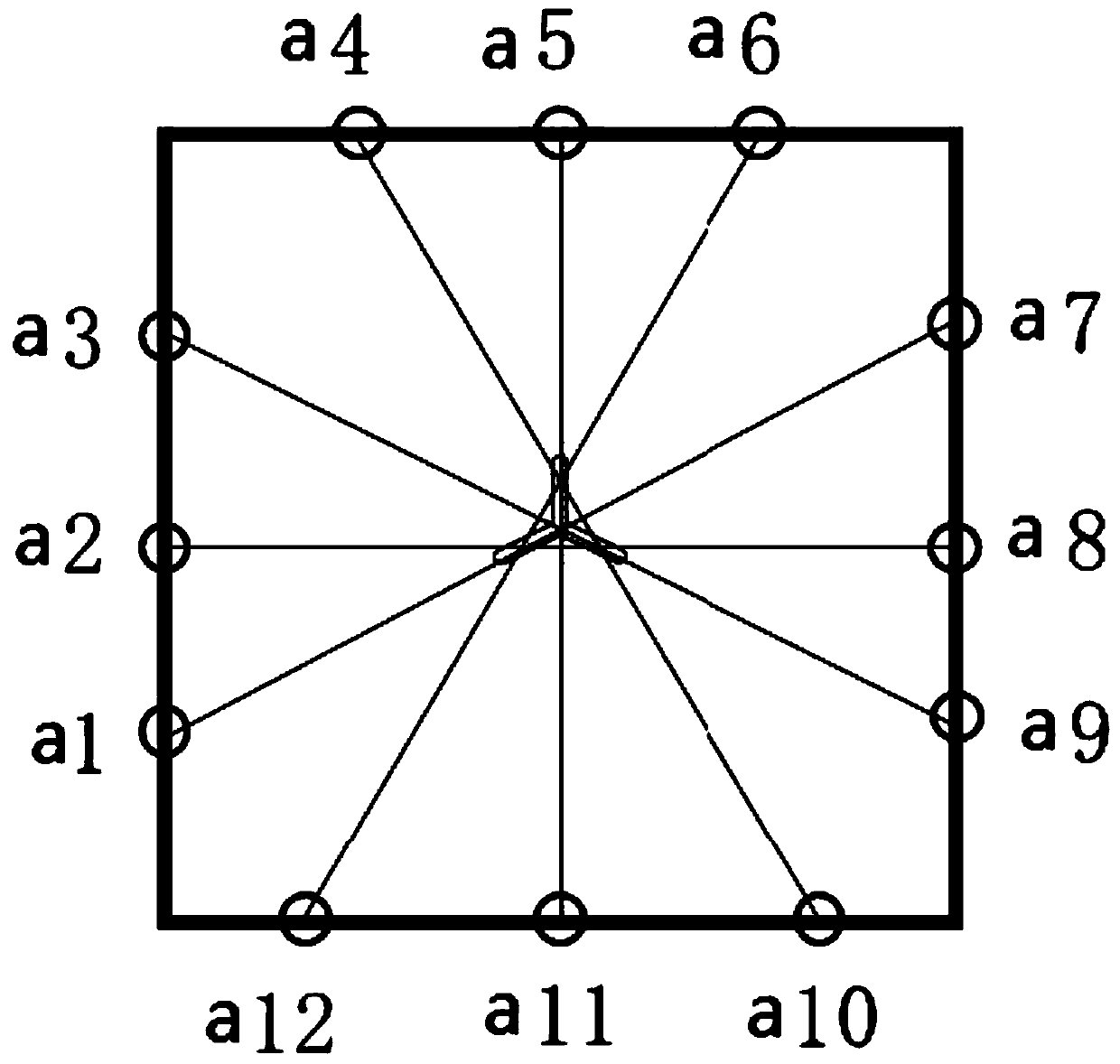

[0031] A method for imaging cracks on the surface of polymer bonded explosives, using a probabilistic damage reconstruction algorithm based on correlation analysis to image cracks with complex shapes, and designing a surface wave silicone probe to excite surface waves according to the characteristics of low sound velocity of the material, successfully obtained The size, position and shape information of surface cracks in complex shapes realize the non-destructive evaluation of surface defects of polymer bonded explosives. Firstly, the surface wave transducer designed and manufactured according to the low sound velocity characteristics of the tested material is introduced. Please refer to figure 1 , The structure of the surface wave transducer includes a plastic shell 1, a sound-absorbing block 2, a cable 3, a backing layer 4, a cable socket 5, a wedge 6, a protective b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com