Method for judging structural segregated band flaws in flat metal plate by using single-crystal straight probe

A technology of flat metal and straight probes, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, material analysis, and use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve problems such as no clear white spots and crack identification methods, and achieve Improves reliability predictability, avoids cracking, provides efficiency and accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with embodiments:

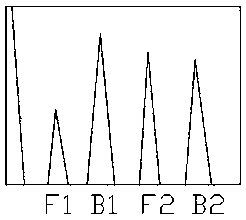

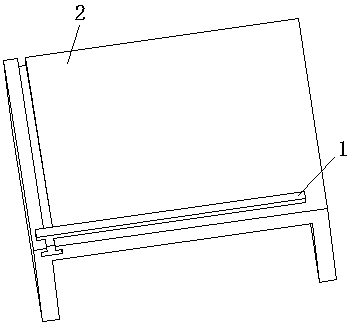

[0029] The method of single crystal straight probe to judge the internal structure segregation defects of flat metal plates is to use the A-type pulse reflection ultrasonic flaw detector, and use the single crystal straight probe to detect the hot-rolled flat steel plate. According to the size of the defect in the hot-rolled flat steel plate, Types and different types of defects have different ultrasonic reciprocating sound pressure transmittances, which can be directly distinguished by comparing the respective echo heights on the oscilloscope screen, mainly by comparing the first defect echo F1 with the first bottom echo B1 The height of the wave crest is used to qualitatively determine whether the defect is a segregation zone of metal structure. Such as figure 1 , 2 As shown, the judgment of defects needs to meet the following conditions at the same time:

[0030] a. The fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com