Energy-saving kiln

An energy-saving, furnace cellar technology, applied in the field of furnace cellars, can solve the problems that blackbody components cannot be reliably installed on the furnace wall for a long time, affect the popularization and application of blackbody energy-saving technology, and insufficient blackbody components to adhere to the furnace wall, etc. To achieve the effect of long-term fixation, simple structure, and high emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a better understanding of the present invention by showing examples of the present invention.

[0015] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

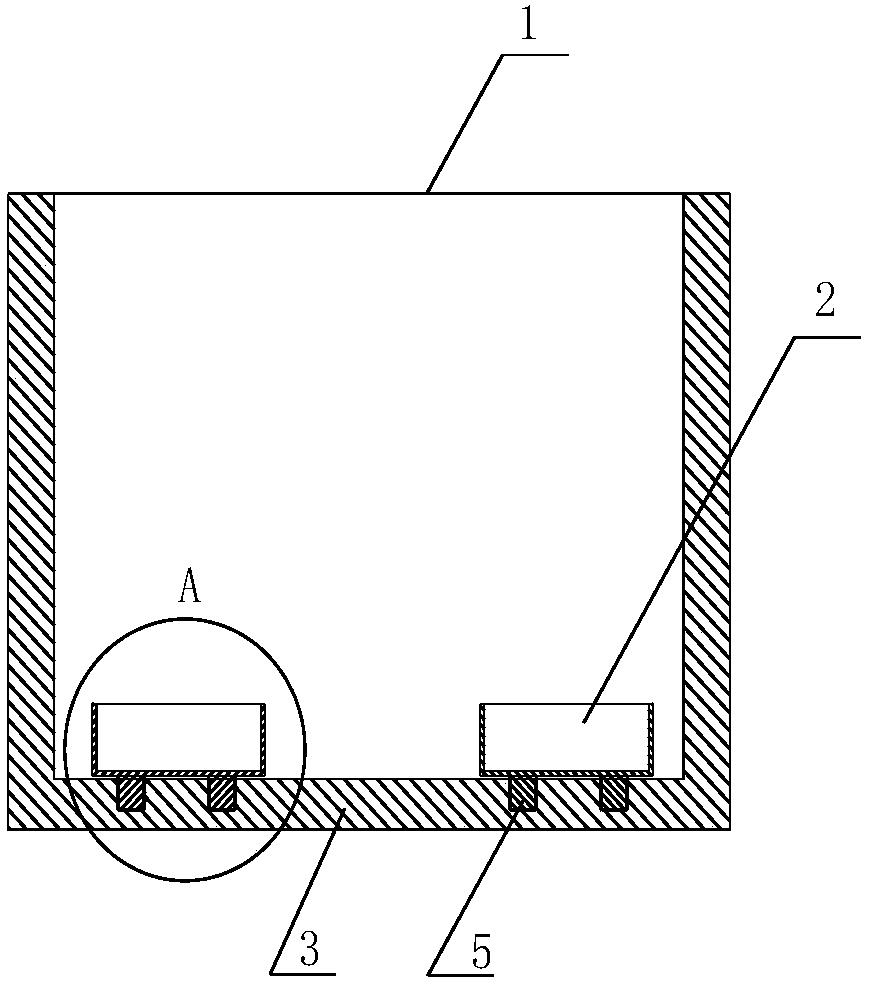

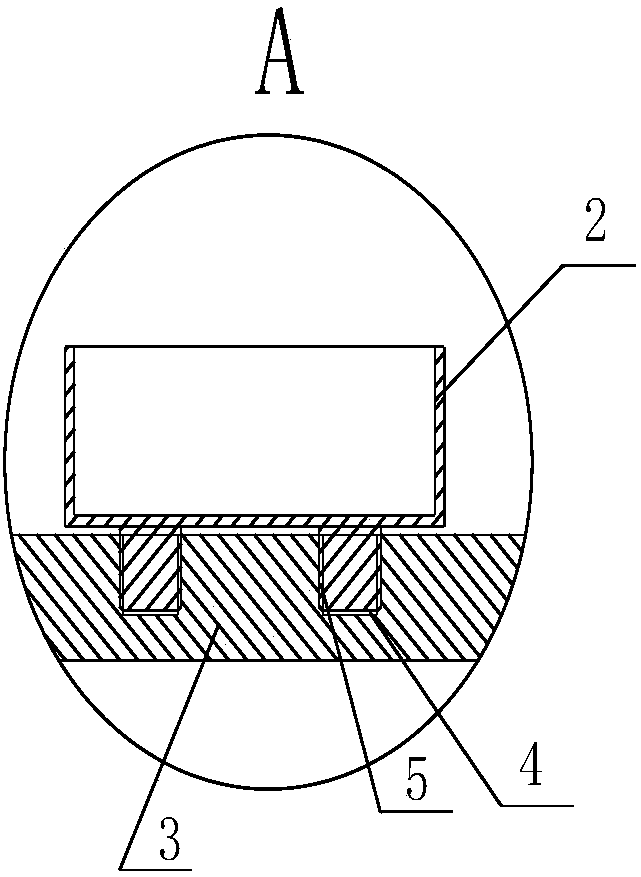

[0016] Such as figure 1 As shown, the present invention provides an energy-saving furnace, including: a furnace body 1, a black body element 2, and a high temperature resistant material; the furnace wall 3 of the furnace body 1 is provided with a mounting hole 4 for the black body element 2; The bottom of the black body element 2 is provided with a boss 5, and the boss 5 is interfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com