Stable low-noise adobe tamping equipment for constructional engineering

A construction engineering and stable technology, applied in construction, infrastructure engineering, soil protection, etc., can solve problems that affect the health of staff, affect the lives of residents, and deteriorate air quality, so as to prevent dust from flying, reduce shaking, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

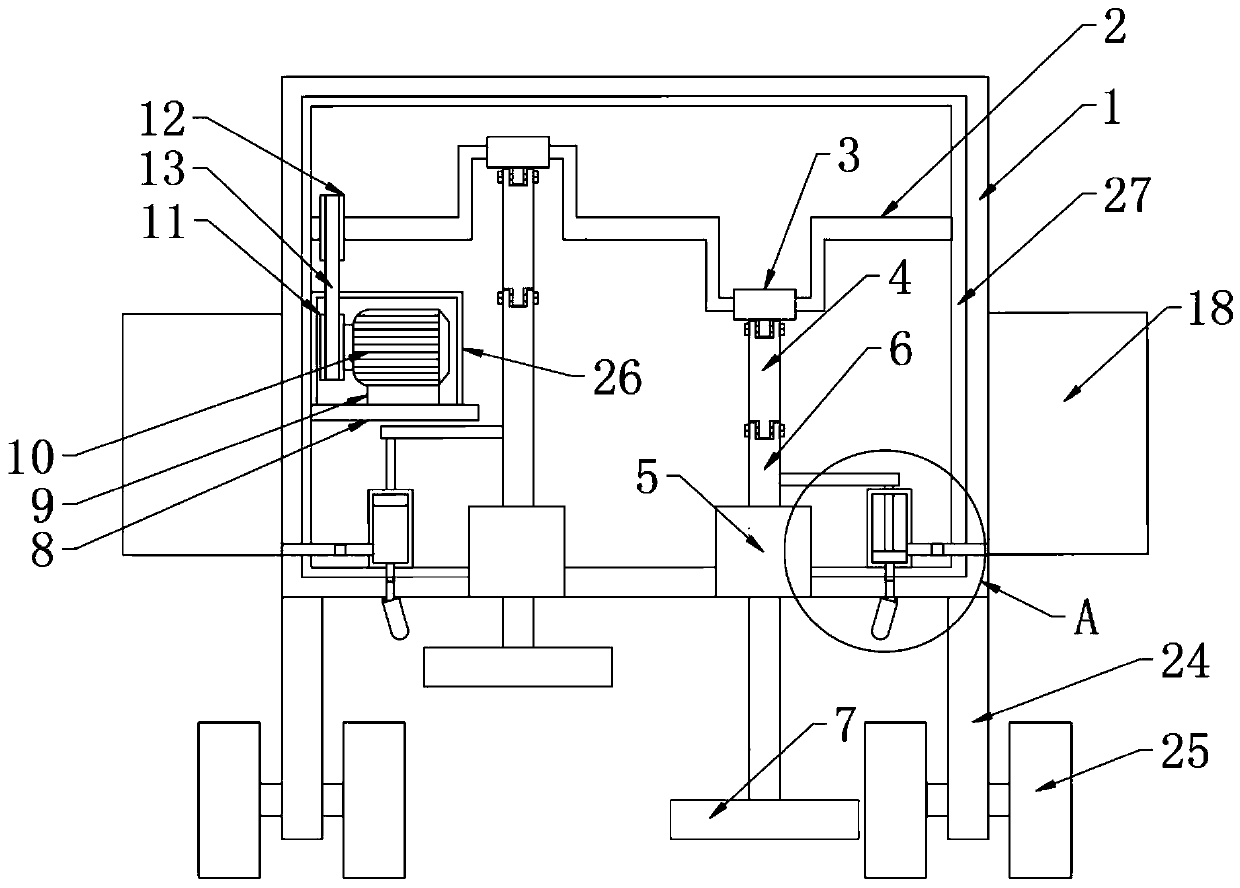

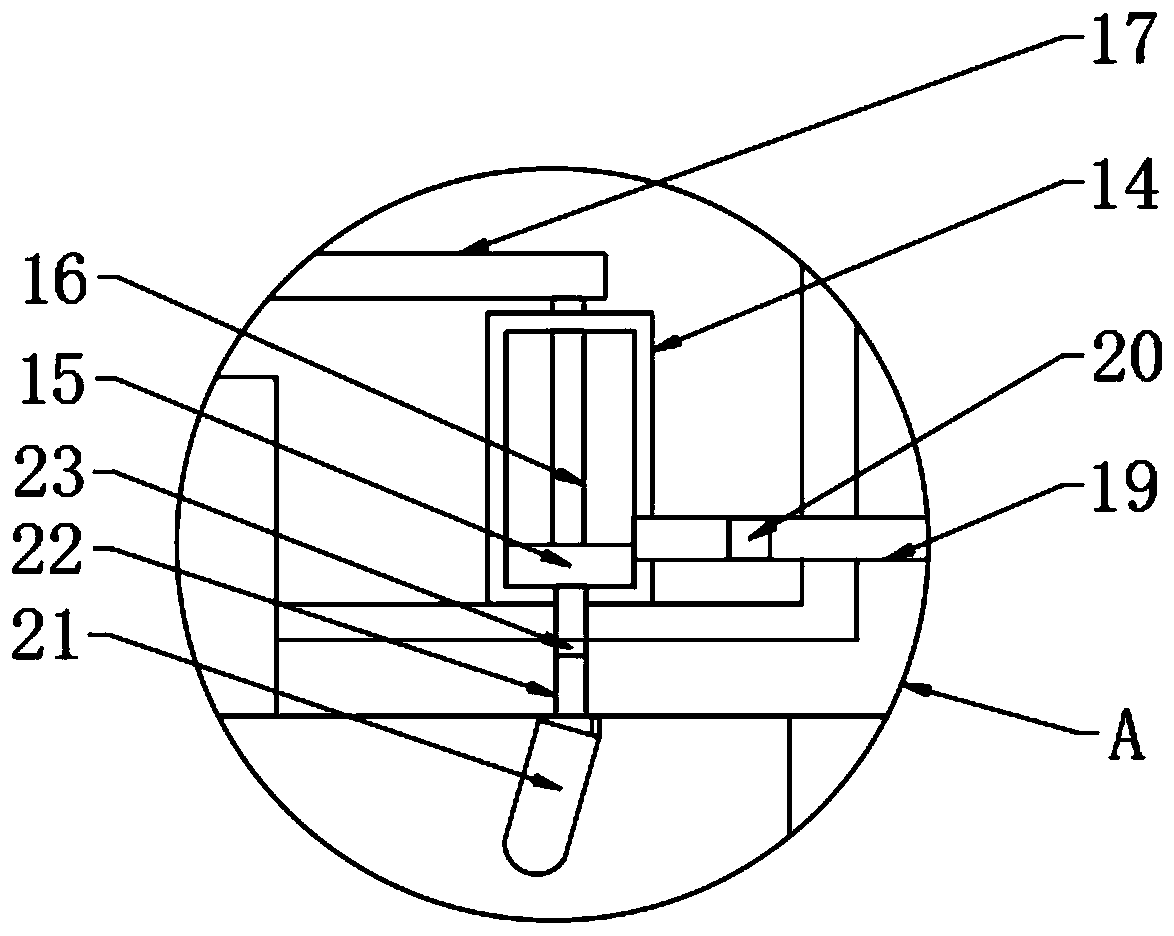

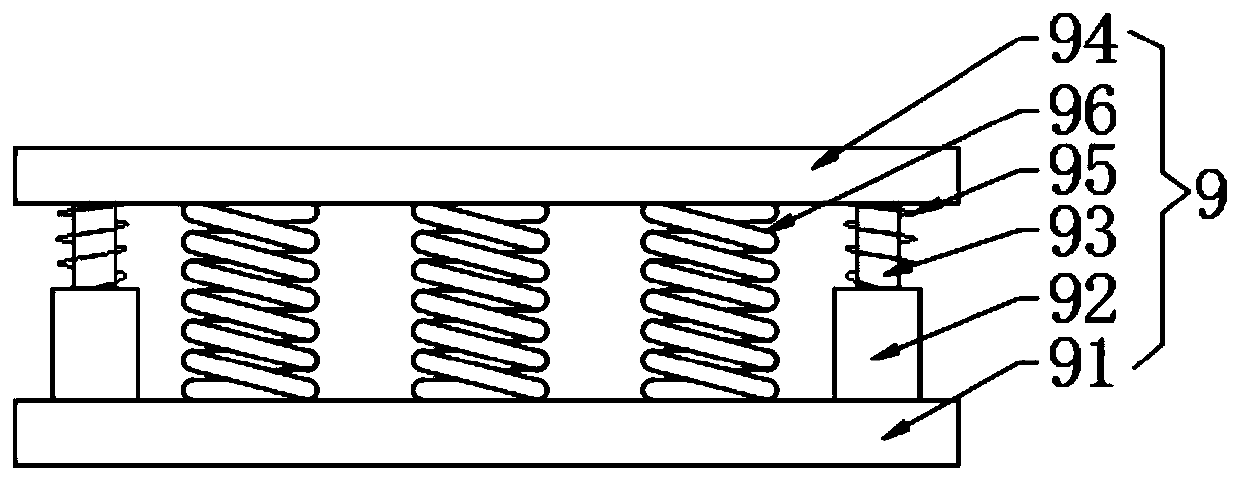

[0024] Embodiment: Move the tamping equipment to a designated position by a hand push frame, make the rammed earth plate 7 directly above the adobe, pour water into the water tank 18, start the driving motor 10, and the driving motor 10 drives the driving gear 11 to rotate, and the driving gear 11 Drive the driven gear 12 to rotate through the chain 13, thereby driving the crankshaft 2 to rotate, the crankshaft 2 drives the rotating pull rod 4 to move up and down through the movable sleeve 3, and the rotating pull rod 4 drives the movable rod 6 to move up and down, thereby driving the rammed earth plate 7 to compact the adobe Operation, when the movable rod 6 moves up and down, it drives the pressure rod 17 to move up and down, thereby driving the piston 15 to move up and down through the push rod 16. When the piston 15 moves upward, the water in the water tank 18 is carried into the sleeve 14 through the connecting pipe 19, and the When the piston 15 moves downward, the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com