A discontinuous phase change temperature-regulating fiber and its preparation method

A technology of temperature-regulating fibers and phase-change fibers, which is applied in fiber processing, fiber chemical characteristics, and rayon manufacturing, etc., can solve the problems of long-term effect and insufficient reliability, and achieve strong temperature-regulating ability, low preparation cost, and reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

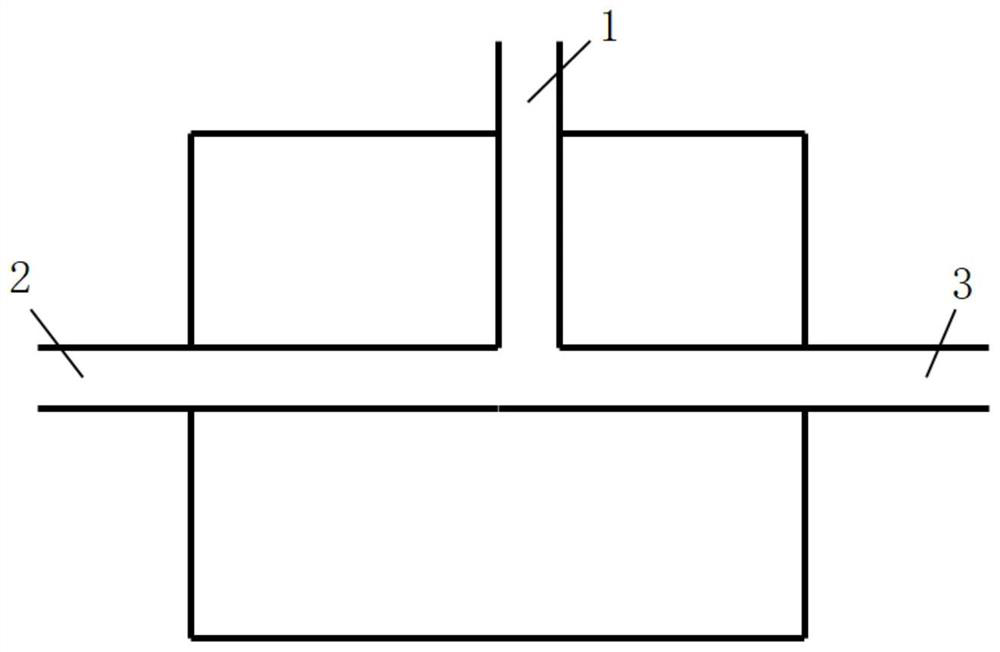

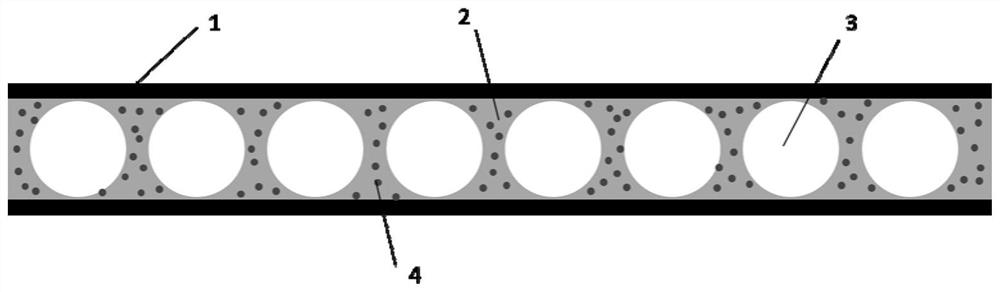

[0030] (1) Accurately weigh 10g of acrylic acid, 0.1g of azobisisobutylcyanide and 0.1g of carbon nanotubes in a 50mL beaker, then use a magnetic stirrer to stir evenly at room temperature at 200r / min, and pass in nitrogen for 10min to obtain a monomer mixture liquid.

[0031] (2) Connect the polypropylene hollow fiber to channel 3 of the microfluidic chip. At 30°C, use a microsyringe pump to inject the monomer mixture into channel 1 at a flow rate of 10 μL / min; at the same time use a microsyringe pump to inject n-octadecane liquid into channel 2 at a flow rate of 8 μL / min. The two liquids are fed into the hollow fiber through channel 3. After the fiber cavity is filled, both ends are heat-sealed to obtain a phase change fiber precursor.

[0032] (3) Place the phase change fiber precursor under a UV lamp (power 500W, dominant wavelength 253nm), fix the distance between the light source and the fiber at 10cm, and irradiate for 60min to polymerize the acrylic acid in the fiber...

Embodiment 2

[0034] (1) Accurately weigh 10g of acrylamide, 0.05g of (2,4,6 trimethylbenzoyl) diphenylphosphine oxide and 1g of boron nitride in a 50mL beaker, and then use a magnetic stirrer at room temperature 200r / min Stir evenly, and pass through nitrogen for 10min to obtain a monomer mixture.

[0035] (2) Connect the polypropylene hollow fiber to channel 3 of the microfluidic chip. At 40°C, use a microsyringe pump to inject the monomer mixture into channel 1 at a flow rate of 9 μL / min; at the same time use a microsyringe pump to inject n-eicosane liquid into channel 2 at a flow rate of 7 μL / min. The two liquids are fed into the hollow fiber through channel 3. After the fiber cavity is filled, both ends are heat-sealed to obtain a phase change fiber precursor.

[0036] (3) Place the phase change fiber precursor under a UV lamp (power 300W, dominant wavelength 366nm), fix the distance between the light source and the fiber at 10cm, and irradiate for 60min to polymerize the acrylamide...

Embodiment 3

[0038] (1) Accurately weigh 10g of methyl methacrylate, 0.08g of 2-isopropylthioxanthone and 0.5g of nano-silver powder in a 50mL beaker, then stir evenly at room temperature at 200r / min with a magnetic stirrer, Nitrogen gas was passed through for 10 minutes to obtain a monomer mixture.

[0039] (2) Connect the polypropylene hollow fiber to channel 3 of the microfluidic chip. At 30°C, use a microsyringe pump to inject the monomer mixture into channel 1 at a flow rate of 10 μL / min; meanwhile use a microsyringe pump to inject PEG2000 into channel 2 at a flow rate of 8 μL / min. The two liquids are fed into the hollow fiber through channel 3. After the fiber cavity is filled, both ends are heat-sealed to obtain a phase change fiber precursor.

[0040] (3) Place the phase change fiber precursor under an ultraviolet lamp (power 600W, dominant wavelength 382nm), fix the distance between the light source and the fiber at 10cm, and irradiate for 60min to polymerize the methyl methacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com