Liquid accelerating agent and preparing method and application thereof

A technology of accelerator and liquid, which is applied in the field of liquid accelerator and its preparation, can solve the problems of high fluorination of drinking water, etc., and achieve the effects of less investment in equipment, low price of finished products, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned chlorine-free, fluorine-free and alkali-free low-cost liquid quick-setting agent comprises the following steps:

[0035] Step 1: At room temperature, add water, amide and silicate into a stirring container for stirring at a stirring speed of 1000-3000r / min, stirring for 2 to 5 minutes to disperse the silicate evenly; then add alcohol amine and continue stirring for 7 ~10min, until the alcohol amine is mixed evenly.

[0036] Step 2, then quickly add aluminum hydroxide and aluminum sulfate into the stirring vessel, and continue stirring for 30-40 minutes until the aluminum hydroxide and aluminum sulfate are uniformly dispersed.

[0037] Step 3, adding phosphoric acid to the stirred solution, and stirring evenly, to obtain the liquid quick-setting agent of the present invention.

[0038] When the liquid quick-setting agent of the present invention is used, according to the experimental conditions of GB / T 35159-2017, the presen...

Embodiment

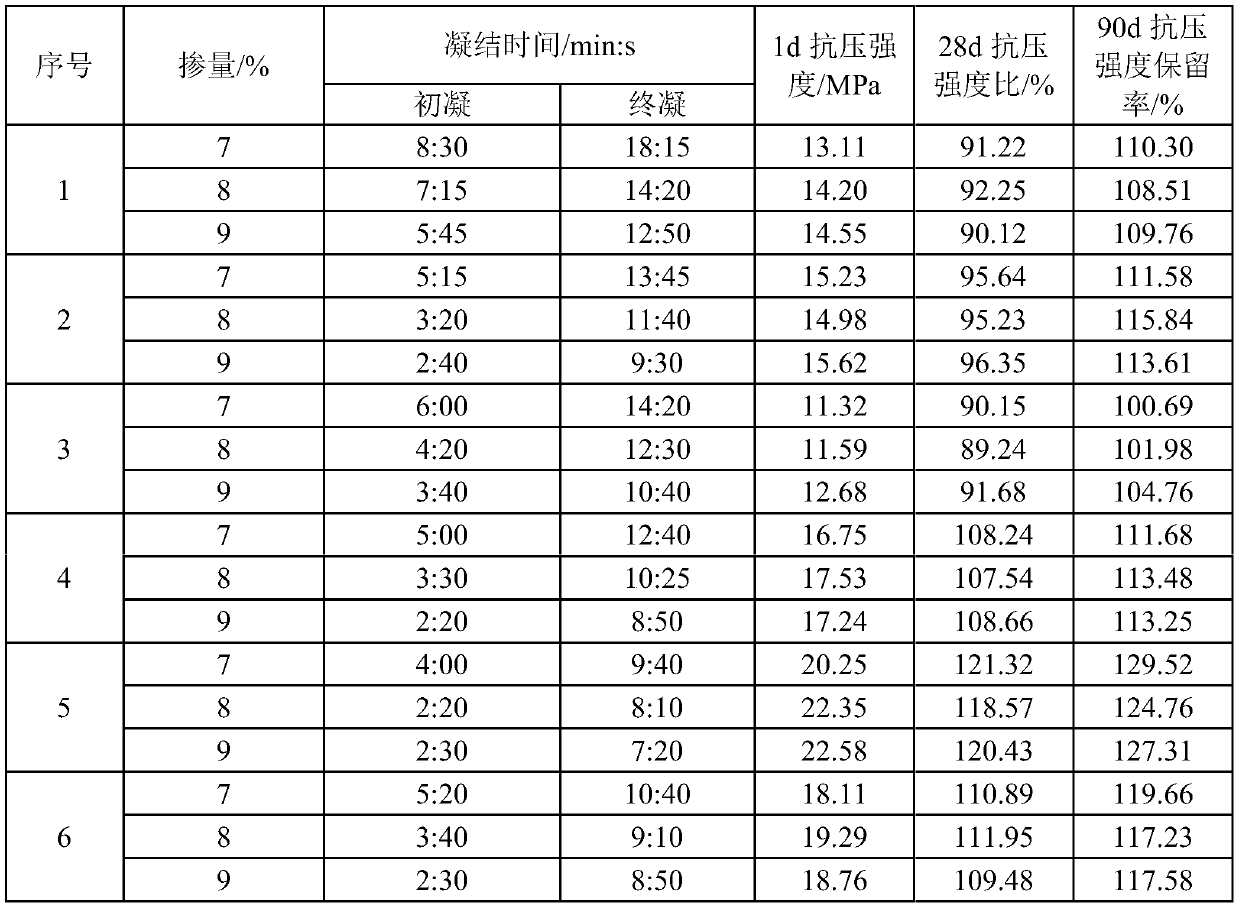

[0040]Use the preparation method of the present invention to carry out the preparation of chlorine-free, fluorine-free and alkali-free liquid quick-setting agent, and according to the test method in standard shotcrete quick-setting agent GB / T 35159-2017, use benchmark cement 400g, water consumption 140g (comprising water contained in the liquid quick-setting agent), according to the recommended amount of cement weight, mixed with chlorine-free, fluorine-free and alkali-free low-cost liquid quick-setting agent, and carried out the setting time measurement experiment; using 900g of benchmark cement, 1350g of standard sand, and 450g of water (including water contained in the liquid quick-setting agent), according to the recommended dosage of cement weight, mixed with chlorine-free, fluorine-free, alkali-free and low-cost liquid quick-setting agent, and carried out the compressive strength measurement experiment. The specific implementation results are shown in Table 1, and the ser...

Embodiment 2

[0042] In Example 2, in step 1, water, formamide and magnesium silicate were added to the stirring container, and the stirring speed was 2000r / min, and the stirring time was 4min; monoethanolamine was added and stirred continuously for 8min until the monoethanolamine was mixed evenly; in step 2 , the stirring time is 35min, until the aluminum hydroxide and aluminum sulfate are uniformly dispersed. The mass percentage of each component is: 60% of aluminum sulfate, 4% of phosphoric acid, 2% of formamide, 6% of aluminum hydroxide, 8% of monoethanolamine, 1% of magnesium silicate, and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com