Freight yard type full-automatic microhole plate washing work station

A micro-plate, fully automatic technology, applied in the stacking, transportation and packaging of objects, cleaning methods and utensils, etc., to achieve the effect of realizing intelligence and mechanization and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

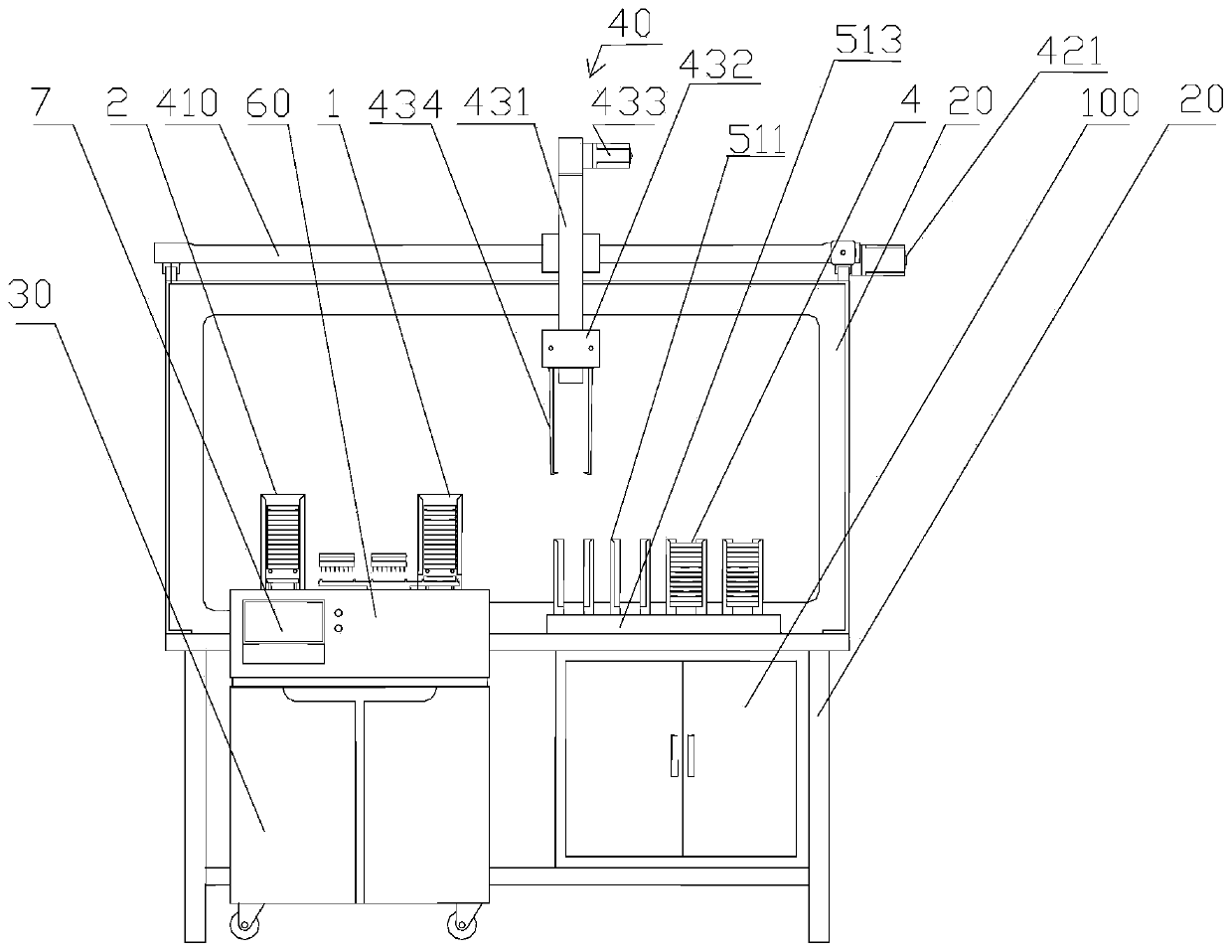

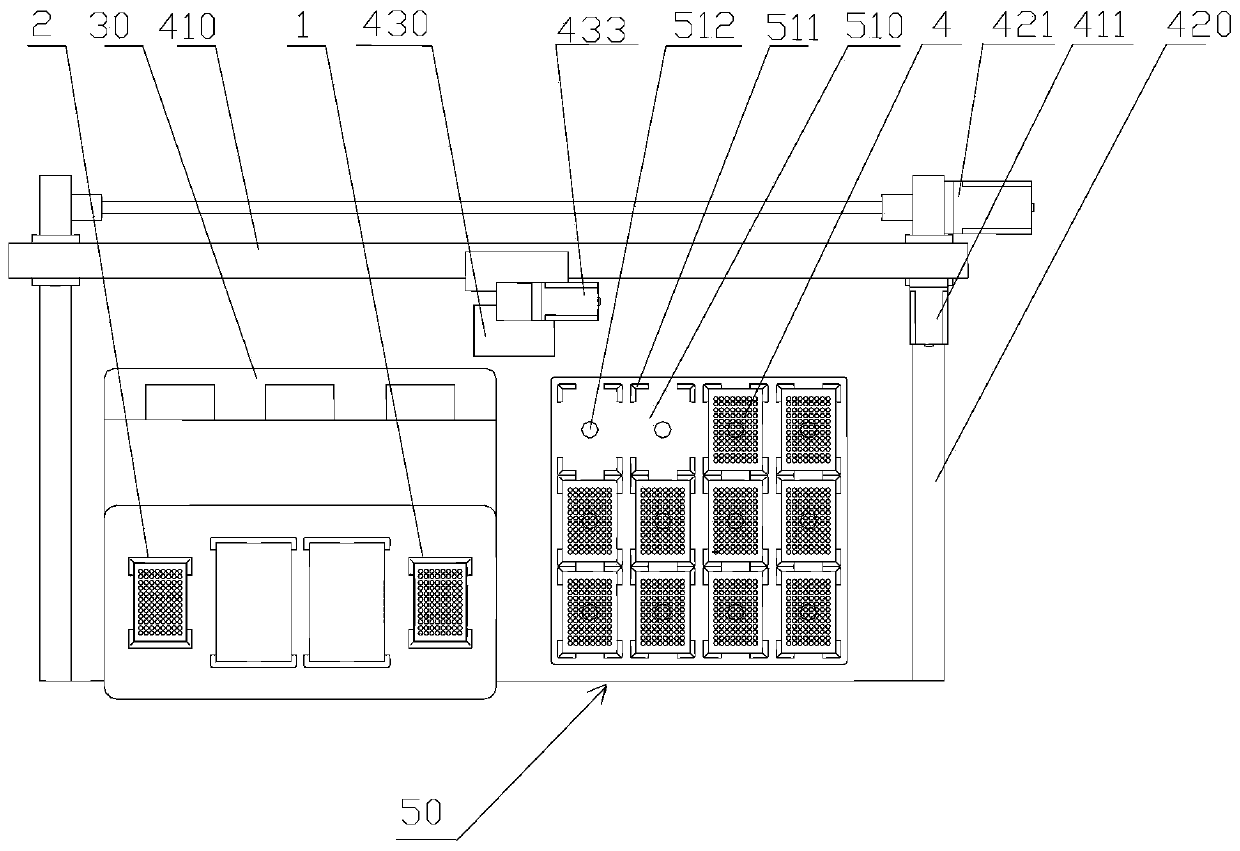

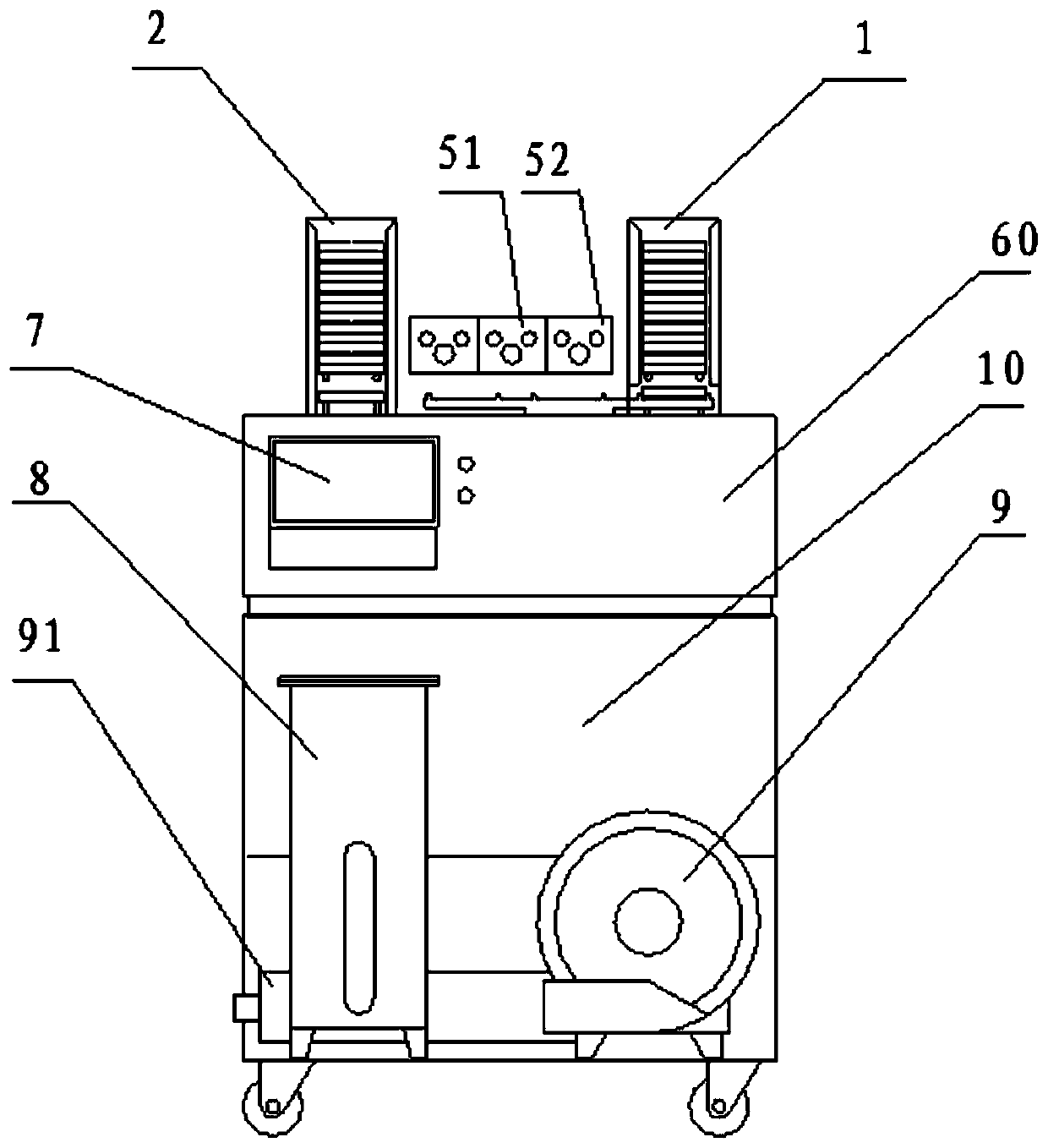

[0047] like Figure 1-11 As shown, a warehouse-type fully automatic microplate washing workstation includes a frame 20, a three-dimensional traveling mechanism 40, and a microplate washer. The three-dimensional traveling mechanism 40 is installed on the frame 20, and the microplate washer is fixed on In the frame 20, a goods yard 50 for storing the microplate 4 is formed in the frame 20; the three-dimensional traveling mechanism 40 is erected above the microplate washing machine and the goods yard 50; Transport to the microplate washer, or transport the microplate 4 processed by the microplate washer back to the yard 50.

[0048] The beneficial effect of this embodiment is: through the three-dimensional walking mechanism 40, the piles of micropore plates 4 to be processed on the goods yard 50 are transported to the microplate washer one by one, and the microplate washer performs the micropore plate 4 Processing, after the processing is completed, the three-dimensional traveli...

Embodiment 2

[0050] like Figure 1-11 as shown,

[0051] A yard-type fully automatic microplate washing workstation, comprising a frame 20, a three-dimensional traveling mechanism 40, and a microplate washer, the three-dimensional traveling mechanism 40 is installed on the frame 20, and the microplate washer is fixed in the frame 20 , the frame 20 is formed with a cargo yard 50 for storing the microplate 4; the three-dimensional traveling mechanism 40 is erected above the microplate washer and the cargo yard 50; the three-dimensional traveling mechanism 40 transports the microplate 4 stored in the cargo yard 50 to the micro The orifice plate washer, or the microporous plate 4 processed by the microorifice plate washer is transported back to the goods yard 50 .

[0052] Through the three-dimensional walking mechanism 40, the stacks of microplates 4 to be processed on the goods yard 50 are transported one by one to the microplate washer, and the microplate washer processes the microplates 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com