Stamping part

A technology of parts and components, applied in the direction of pushing out equipment, etc., can solve the problems of large drop height and workpiece deformation, and achieve the effect of small drop height, uniform force and large coverage area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

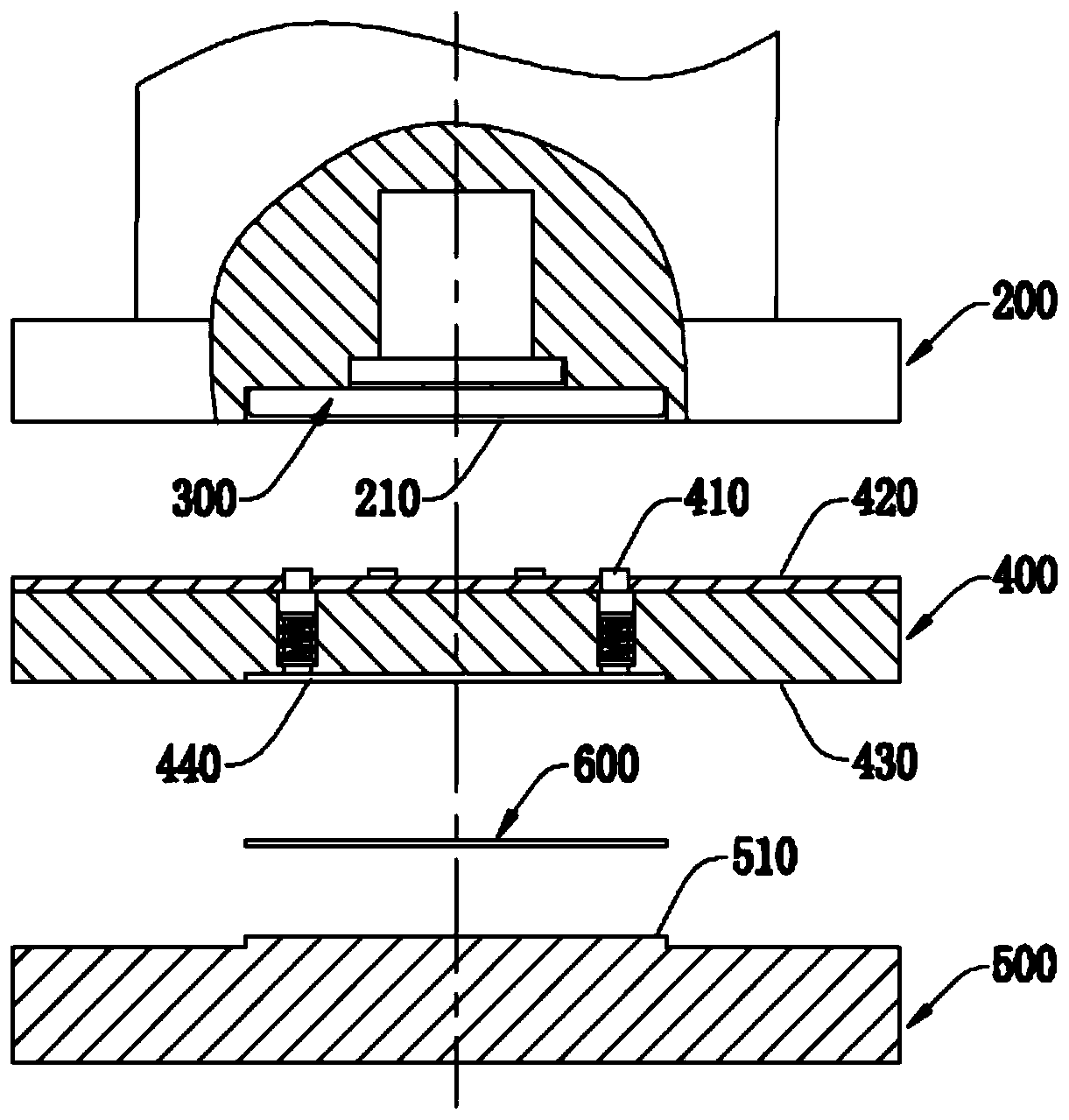

[0039] A stamped part such as figure 1As shown, the stamping part has: a die base 200, which is installed on a punch press and driven to move up and down by the punch press; an upper mold assembly 400, which is fixed on the bottom of the die base 200, moves with the die base 200, and moves up and down. The mold assembly 400 is detachably connected to the mold base 200 by bolts; the lower mold 500 is fixed on the punch press and is positioned on the mounting platform below the upper mold assembly 400, and cooperates with the upper mold assembly 400 up and down, and the lower mold 500 is detachably connected to the installation platform by bolts; the bottom of the mold base 200 is provided with an oil cylinder feeding device 300, and the upper mold assembly 400 is provided with a floating ejector assembly 410 that can float up and down, and the oil cylinder feeding device 300 against the upper end of the floating mandrel assembly 410, the lower end of the floating mandrel assemb...

Embodiment 2

[0044] A stamping part of this embodiment, the basic structure is the same as that of embodiment 1, the differences and improvements are as follows: Figure 4 As shown, the oil cylinder feeding device 300 includes an oil cylinder 310 and a material stripping plate 320, the oil cylinder 310 is fixed upside down on the bottom of the mold base 200, and is connected with the bottom of the mold base 200 by bolts, and the stripping plate 320 is fixed on The end of the piston rod 311 of the oil cylinder 310 is driven by the piston rod 311 to move the stripping plate 320 up and down.

[0045] After the oil cylinder 310 is started, the piston rod 311 stretches out to drive the stripper plate 320 to move downward, and the bottom of the stripper plate 320 bears against the upper end of the floating ejector rod assembly 410, making it move into the mold core groove 440, and the workpiece 600 is removed from the mold. The core groove 440 is ejected to achieve the purpose of separating the ...

Embodiment 3

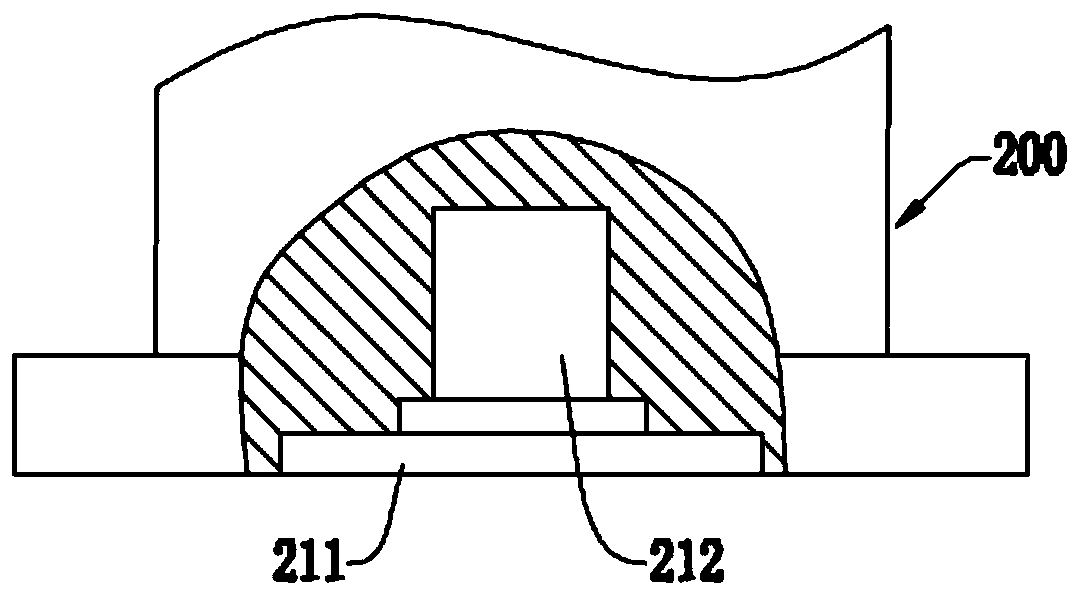

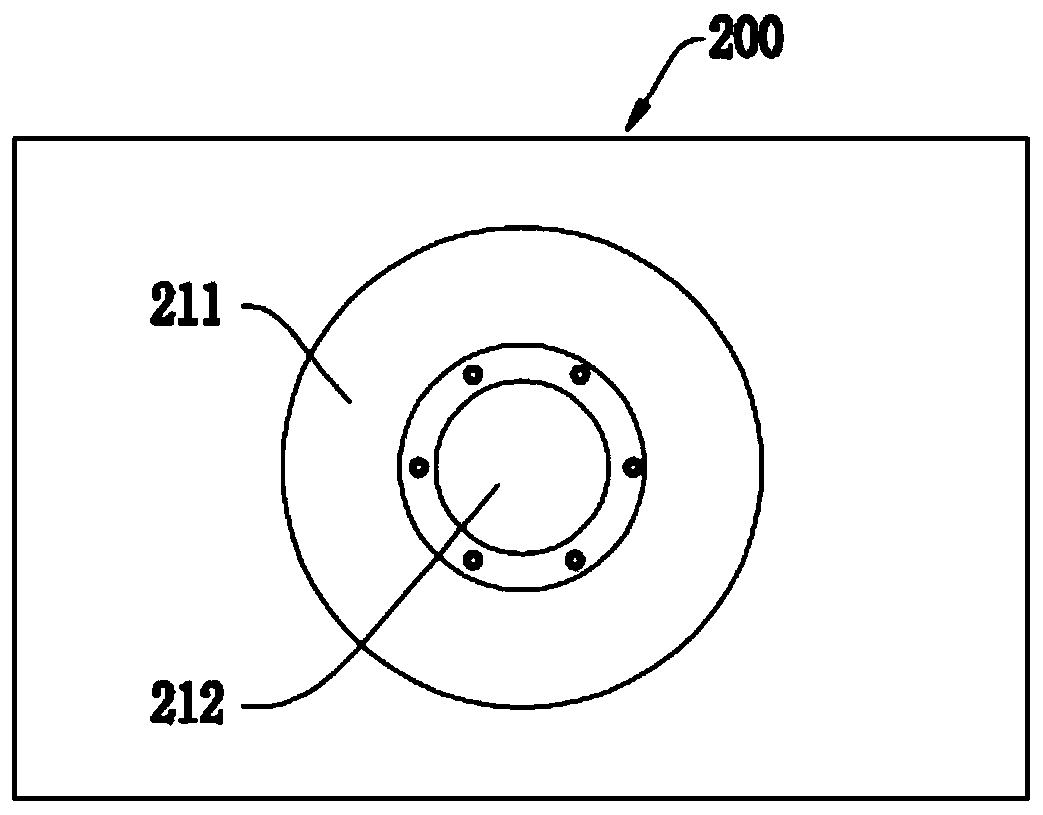

[0048] A stamping part of this embodiment, the basic structure is the same as that of embodiment 2, the differences and improvements are as follows: figure 1 As shown, the bottom of the mold base 200 is provided with an installation groove 210, and the oil cylinder beating device 300 is arranged in the installation groove 210, so as to make room for the installation position of the upper mold assembly 400.

[0049] The installation groove 210 is a cylindrical straight groove or a stepped groove. In this embodiment, the installation groove 210 is a cylindrical straight groove with a uniform inner diameter along its axis, which is easy to process.

[0050] During the blanking process, the oil cylinder 310 is started, and the piston rod 311 is stretched out to push the stripper plate 320 out of the installation groove 210, and the stripper plate 320 moves against the floating ejector rod assembly 410, pushing the workpiece 600 out of the mold core groove 440 Then control the pist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com